Introduction

This article provides an in-depth analysis of electric heaters and their benefits.

Key topics include:

- What is an Electric Heater

- Components of Electric Heaters

- Types of Electric Heaters

- Advantages and Disadvantages of Electric Heating

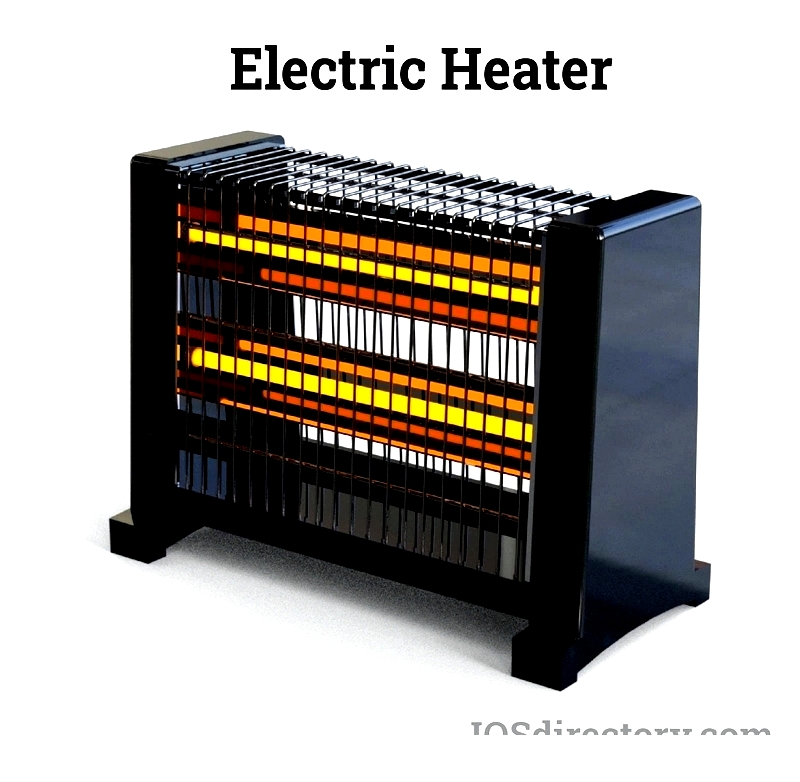

Chapter 1: What is an Electric Heater?

Electric heating works through a resistor in a circuit that has limited free electrons, making it resistant to electrical conduction. When electrons encounter this resistance, heat is generated, providing the necessary energy for electric devices to function. Although highly efficient, electric heating can be costly due to its significant electricity consumption. Electricity typically costs more than other energy sources like water, gas, and fossil fuels. However, electric heaters often have lower upfront and installation costs, making them attractive to consumers. For home use, electric heaters are usually insulated with plastic to prevent shocks and reduce energy waste.

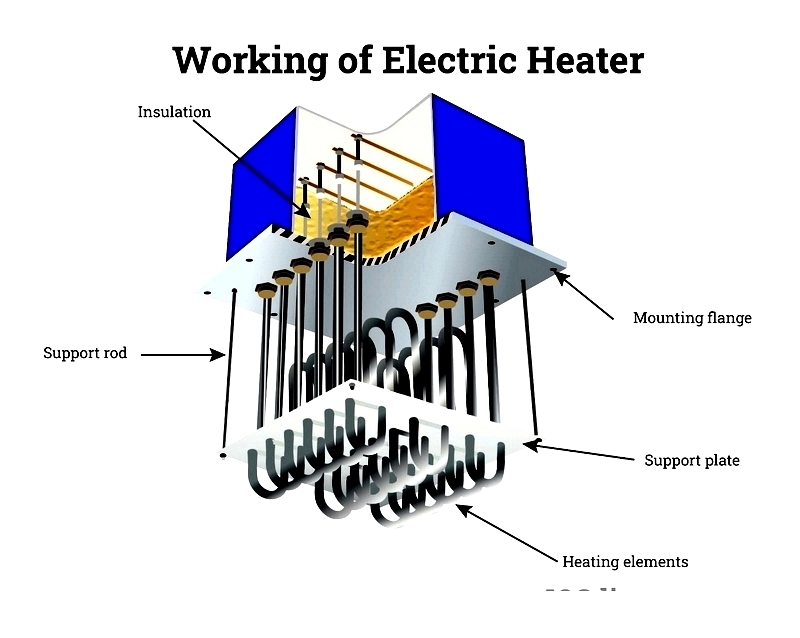

Chapter 2: What Is The Design of an Electric Heater

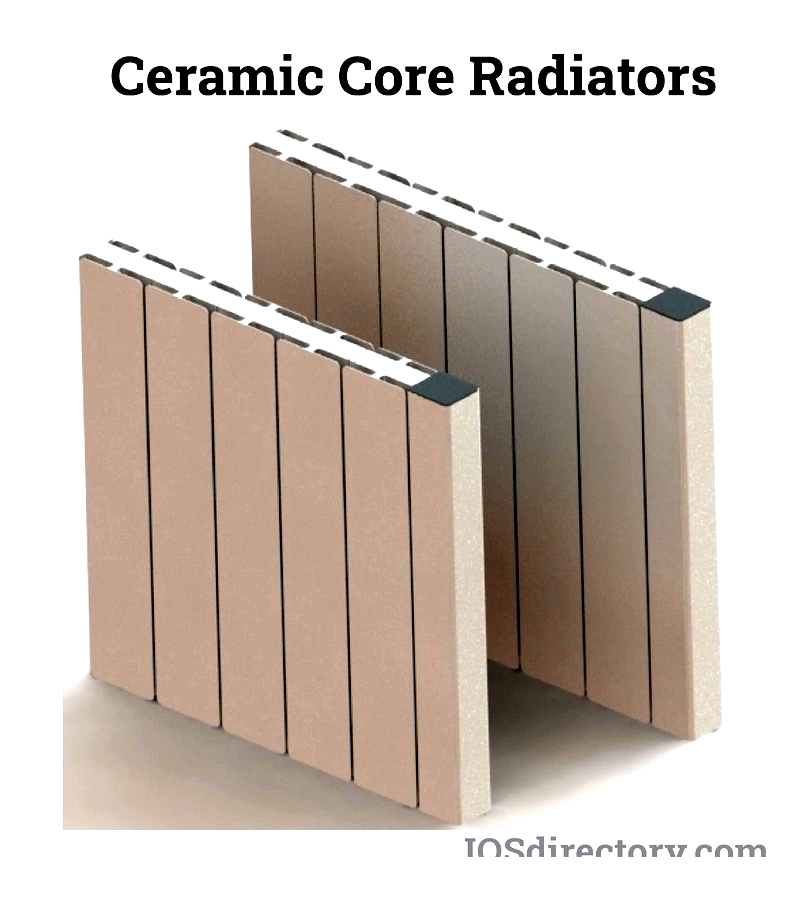

Electric heaters are essential components in residential, commercial, and industrial heating systems, valued for their efficiency, safety, and versatility. The basic design consists of a heating core that produces warmth when an electric current passes through it. Two primary types of heating cores are used: oil-filled heaters and dry core electric radiators. Dry cores, often made from durable ceramic elements, are lightweight, leak-proof, and highly reliable. These ceramic core radiators are known for their energy efficiency and excellent heat retention, making them a top choice for modern energy-saving heating solutions. The outer casing is typically made from heat-conductive metals like aluminum or steel, which help distribute heat quickly, improving performance and reducing energy costs.

Oil-filled electric radiators use thermal oil heated by internal elements to provide consistent radiant and convective warmth. These heaters require no maintenance or oil refills during their lifespan and are favored for their steady heat output. The heat-transfer fluid remains stable, ensuring optimal performance. Resistor coils in electric heaters come in various forms, including exposed coils on insulators, resistance elements embedded in insulation with protective casings, or precision elements integrated into printed circuits. Advanced designs often feature expanded fins to increase surface area, enhancing heat dissipation—ideal for space heaters that require quick and even heating.

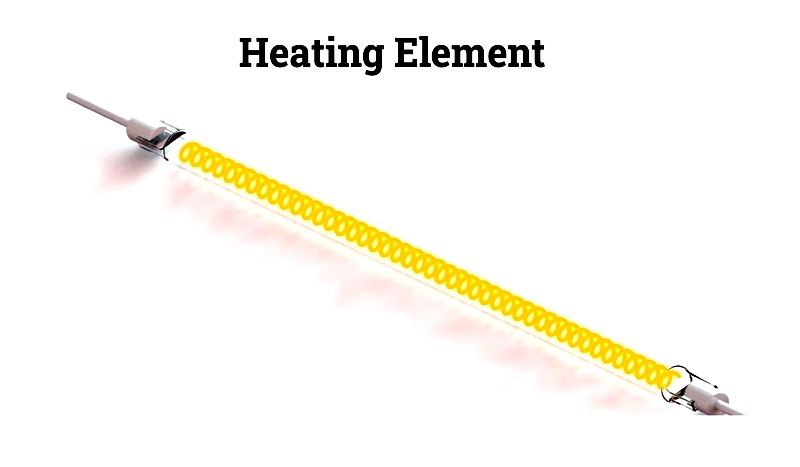

A key component of every electric heater is the heating element, which acts as an electrical resistor. These elements are typically made from high-temperature materials like nichrome wire (nickel-chromium alloy) or other specialized alloys. Electric heaters convert electricity into heat through Joule heating, following Joule's Law. Heating elements can be made from metal alloy wires, carbon composites, or printed-circuit layouts for applications such as infrared heaters and baseboard heaters. Modern devices often use nichrome wires with ceramic insulation for safety, durability, and efficient heat transfer.

Types of Wire in Electric Heating

Selecting the right resistance heating wire is crucial for safety, efficiency, and performance in electric heating systems. There are three main types of electric resistance heating wires, each suited to specific heater designs and requirements. Understanding these wires helps consumers and engineers make informed choices for both household and industrial heating solutions.

Open Wire

Open wire heating elements use nickel-chromium wire mounted on ceramic or mica insulation. These are found in fan heaters, toaster ovens, and lab equipment. Proper enclosure is essential, as exposed wires pose a shock risk if touched. Despite this, open wire heaters are valued for their fast heat output.

Open Ribbon Wire

Similar to open wire, open ribbon wire heats faster due to its larger surface area. This type is used in industrial ovens, electric grills, and strip heaters. However, the increased exposure heightens shock risks, requiring strict safety measures and compliance with standards.

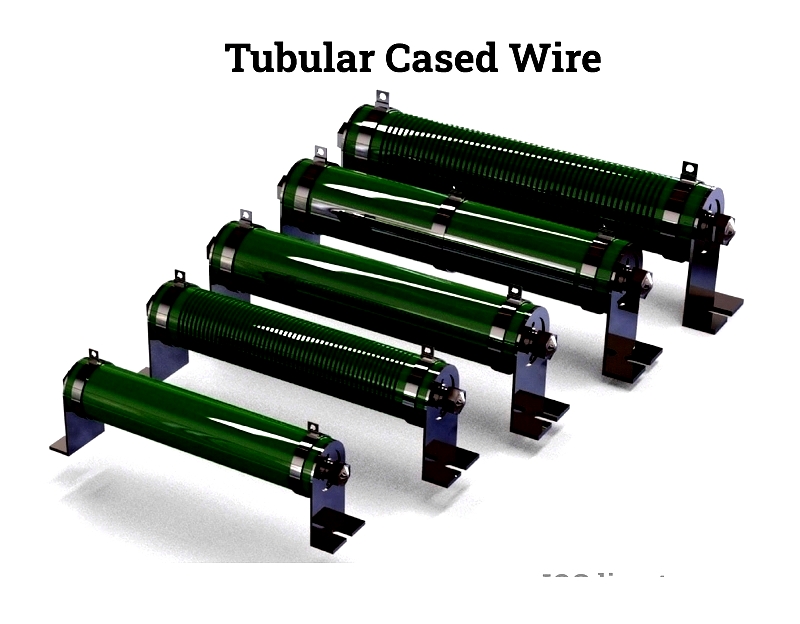

Tubular Cased Wire

Tubular cased wire is the foundation of most modern heating elements, offering efficiency, protection, and durability. These elements feature nickel-chromium wire encased in magnesium oxide powder and sealed in a steel tube. They are used in baseboard heaters, immersion heaters, tankless water heaters, and industrial heat exchangers. Encased wires protect users from shocks and ensure long-lasting performance across various applications.

Working of Electric Heaters

Electric heaters use Joule heating to convert electricity into controllable thermal energy. When activated, current flows through the resistive element, generating heat that warms the surrounding area. Convection heaters circulate warm air naturally, while radiant or infrared heaters direct heat to objects and people. Many models include thermostats, timers, and temperature controls for customization and energy savings. This combination of efficiency, safety, and control makes electric heaters ideal for homes, offices, and industrial spaces.

When choosing an electric heater, consider factors like energy efficiency, heating capacity, safety certifications, and intended use. Manufacturers continue to innovate, improving reliability, reducing environmental impact, and adding features like smart controls. Understanding electric heater design and operation helps buyers make informed decisions for optimal comfort and value.