Introduction

This article provides an in-depth exploration of conveyor ovens.

You will learn about the following topics:

- What is a conveyor oven?

- Types of conveyor ovens

- Types of conveyor belts for conveyor ovens

- Applications of conveyor ovens

- And much more…

Chapter One - What is a Conveyor Oven?

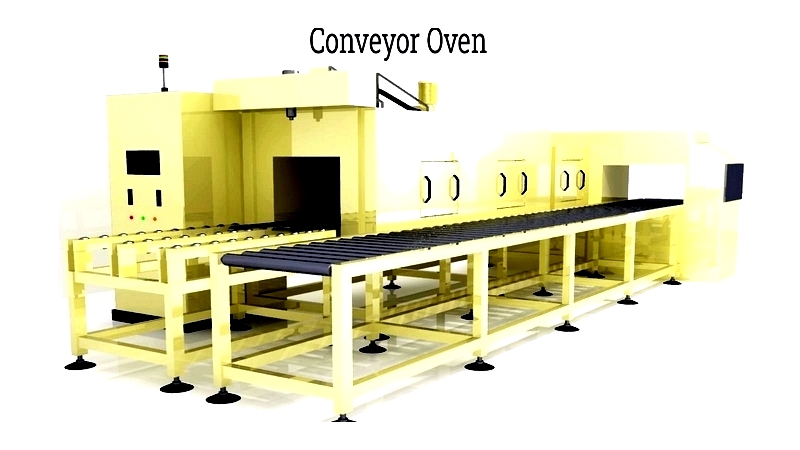

A conveyor oven is a continuous flow oven with open ends and a conveyor belt that runs from one side to the other. Similar in design to batch ovens, conveyor ovens offer the added benefit of keeping products in motion while ensuring consistent and even heating. They are particularly suitable for mass production and large-volume manufacturing processes.

Conveyor ovens come in various designs, including horizontal, vertical, inclined, and spiral configurations. Different conveying methods such as powered rollers, belts, chain-on-edge, overhead systems, and power-and-free arrangements are also available. These setups are ideal for high-output production facilities where time efficiency makes batch ovens impractical.

Conveyor ovens incorporate diverse conveying systems, including overhead systems, chain-on-edge, rollers, belts, and various chain setups in different dimensions and configurations. These systems can accommodate products ranging from a few pounds to several hundred pounds.

Chapter Two - What are the different types of conveyor ovens?

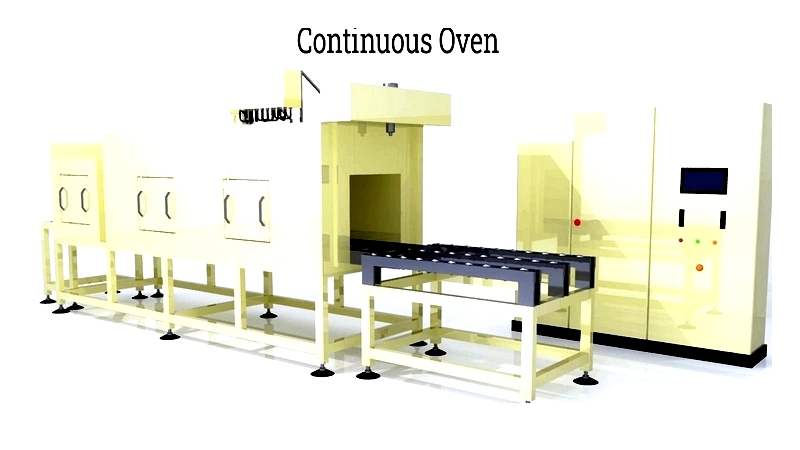

Industrial ovens play a crucial role in modern manufacturing, food processing, and finishing industries by providing a controlled, high-temperature environment for essential heat treatment processes such as curing, drying, annealing, or baking. These thermal processing systems feature fully enclosed heating chambers to ensure uniform and repeatable results. Conveyor ovens are a specialized category of industrial ovens designed for high-throughput and continuous processing. By using automated conveying systems, they enable consistent movement of parts, products, or food items through controlled heat zones, maximizing efficiency, reliability, and product uniformity.

Modern custom conveyor oven systems are engineered to meet specific throughput requirements, material types, and product dimensions. These industrial solutions incorporate various conveyor technologies—such as belt, chain-on-edge, overhead, and carousel methods—along with diverse heating elements like electric, infrared, gas-fired, and hybrid systems. The strategic configuration of airflow (horizontal/vertical or vertical/horizontal) and multi-zone temperature controls further optimizes process consistency and energy efficiency, serving critical needs in sectors like automotive, aerospace, electronics, and food production.

Vertical Conveyor Ovens

Vertical conveyor ovens, including advanced paternoster models, are ideal for manufacturing environments with limited floor space. These ovens use automated trays that cycle continuously or in stages, attached to conveyor chains in a vertically looping sequence. Known for their compact footprint, vertical conveyor ovens offer excellent temperature uniformity, long equipment lifespan, reliable operation, and minimal maintenance. Their ergonomic design simplifies loading and unloading, making them easy to integrate into batch and continuous processing lines for applications like powder coating, composite curing, and electronics drying.

Overhead Conveyor Ovens

Overhead conveyor ovens use a rugged monorail-style mechanism to transport parts or products through multiple processing zones. These ovens excel in high-volume operations such as parts finishing, paint curing, or thermal cleaning, where automated handling and high throughput are essential. Heavy-duty conveyor chains, capable of navigating vertical and horizontal curves, allow for customized layouts that maximize floor space and workflow efficiency. Overhead conveyor ovens feature airtight entrances to prevent heat loss and contamination, with conveying paths designed in serpentine or looped circuits for energy efficiency and optimized dwell time. These systems are widely used in automotive, metalworking, and appliance manufacturing.

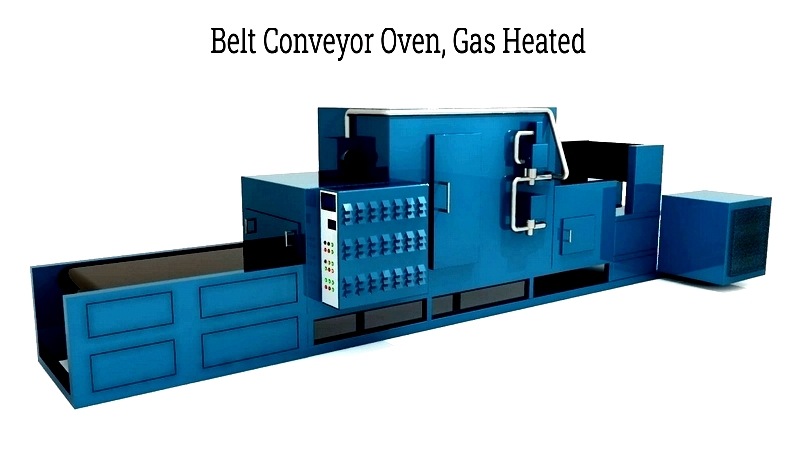

Belt Conveyor Ovens

Belt conveyor ovens use heat-resistant woven wire or mesh belts to convey parts through the heating process. These continuous ovens are highly flexible for processing large quantities of small to medium-sized components, such as stamped metal parts, circuit boards, or food products. The conveyor belt can be adjusted for continuous transport or indexing, depending on dwell time and production flow. Precise temperature controls, zoned heating, and adjustable speeds make these ovens adaptable for preheating, drying, curing, and dehydration. Open or closed mesh belt designs ensure optimal airflow for uniform thermal profiles and consistent product quality.

Chain-On-Edge Conveyor Ovens

Chain-on-edge conveyor ovens, also known as spindle conveyors, feature robust floor- or frame-mounted chain drives. Fixtures or spindles attached to the chain securely hold parts in place, maintaining precise orientation as they move through heating zones. This system is ideal for coating, drying, or curing small, cylindrical, or irregularly shaped items like bearings, rollers, fasteners, or painted components, ensuring 360-degree exposure to heat or coating sprays. Multiple passes and multi-zone control offer process flexibility for continuous or indexed operation, accommodating complex production demands with ease.

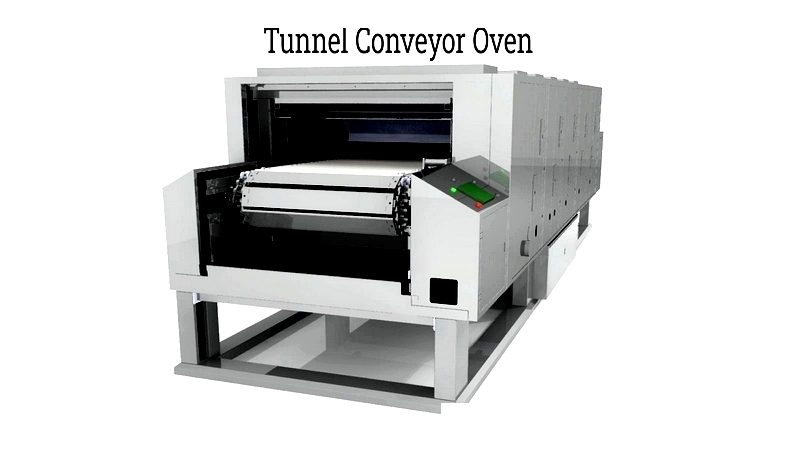

Tunnel Conveyor Ovens

Tunnel ovens are a core technology for high-capacity, continuous-flow thermal processing in industries like commercial baking, pizza production, snack manufacturing, ceramics calcination, and powder coating. These linear ovens offer configurable dimensions, high-temperature capabilities, and precise zone-by-zone temperature control for superior consistency. Tunnel conveyor ovens support various heat sources, including electric, infrared, and gas-fired systems, enabling rapid, energy-efficient processing. Their modular design allows seamless integration with automated conveyor lines, supporting large-scale, 24/7 production and regulatory compliance for safety, hygiene, and emissions.

Carousel Conveyor Ovens

Carousel conveyor ovens are ideal for operations requiring flexible loading and unloading at a single point, enhancing operator safety and workflow efficiency. These compact ovens use circular or oval conveyor paths, combining horizontal airflow for even temperature distribution with space-saving design. They are perfect for precision heat treating, solder reflow, or batch drying, where variable load sizes and frequent part changes are needed. Carousel ovens ensure high repeatability and easy integration into laboratory, electronics, and high-mix manufacturing environments.

Hybrid Conveyor Ovens

Hybrid conveyor ovens combine multiple heating technologies in a single system for customized performance. Common combinations include gas-fired heat with radiant panels or convection and infrared heating for energy efficiency and rapid processing. These ovens are tailored for complex needs like multi-stage paint curing, adhesive drying, or advanced material processing, where variable temperature profiles and targeted heat application are critical. By selecting the right hybrid configuration, manufacturers can optimize costs, reduce cycle times, and improve product quality while meeting compliance and sustainability goals.