Introduction

This article offers detailed insights into NEMA enclosures, covering their manufacturing process, construction materials, applications, advantages, and limitations.

Continue reading to find answers to questions such as:

- What does NEMA stand for?

- How do NEMA enclosures safeguard electrical and electronic equipment?

- What distinguishes NEMA ratings from ingress protection (IP) ratings?

- How are UL and NFPA standards connected to NEMA enclosures?

- What materials and manufacturing processes are used for NEMA enclosures?

- What varieties and dimensions of NEMA enclosures do top manufacturers offer?

- How should NEMA enclosures be specified when ordering or submitting an RFQ?

- Where are NEMA enclosures typically used?

- And more

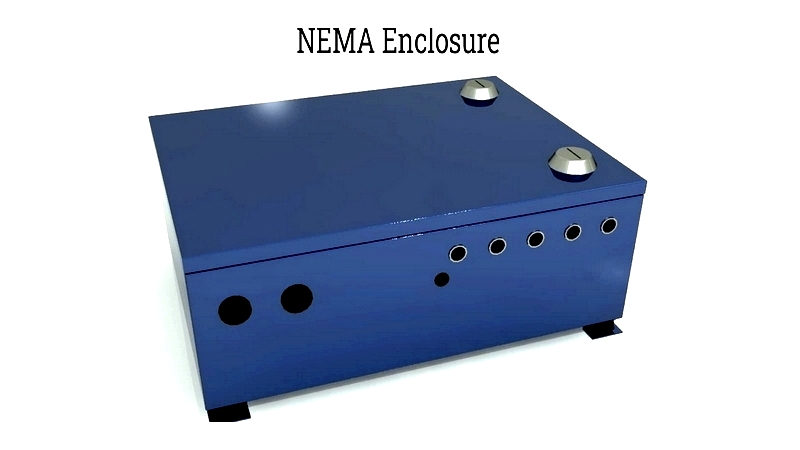

What are NEMA Enclosures?

NEMA enclosures are specialized containers engineered to shield electrical components from environmental factors. Depending on their NEMA rating, these enclosures provide various levels of protection, including:

- Indoor, outdoor, or combined indoor/outdoor applications

- Defense against moderately wet conditions like dripping water and light splashes

- Environments requiring regular hose-downs or occasional water submersion

- Outdoor settings exposed to snow, sleet, or ice, including industrial freezers for food processing

- Dusty industrial environments such as factories, mining operations, and oil & gas facilities

- Areas with exposure to greases, oils, solvents, and non-corrosive coolants

- Corrosive environments containing saltwater, acids, or alkaline solutions

NEMA enclosures not only protect internal equipment but also safeguard workers and surrounding property:

- Explosion-proof NEMA enclosures can contain internal explosions, preventing ignition of volatile chemicals in hazardous areas.

- They prevent worker injuries by shielding against contact with electrical components.

- Lockable enclosures deter unauthorized access to electrical and electronic equipment.