Introduction

This section provides an overview of factory automation along with a list of companies that offer, implement, and plan automation solutions.

You will learn about:

- The fundamentals of Factory Automation

- Different types of Factory Automation

- Planning and implementation of Factory Automation

- Equipment used in Factory Automation

- And more...

Chapter 1: Understanding Factory Automation

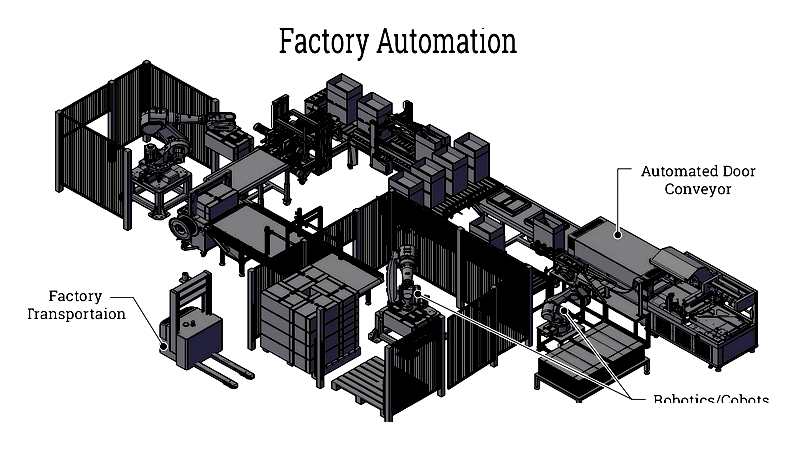

Factory automation integrates advanced technological processes to enhance productivity, increase manufacturing output, and significantly improve production efficiency. Through streamlined operations, products are manufactured, assembled, packaged, and prepared for distribution. At its core, factory automation relies on computer programming to efficiently manage each phase of processing and production.

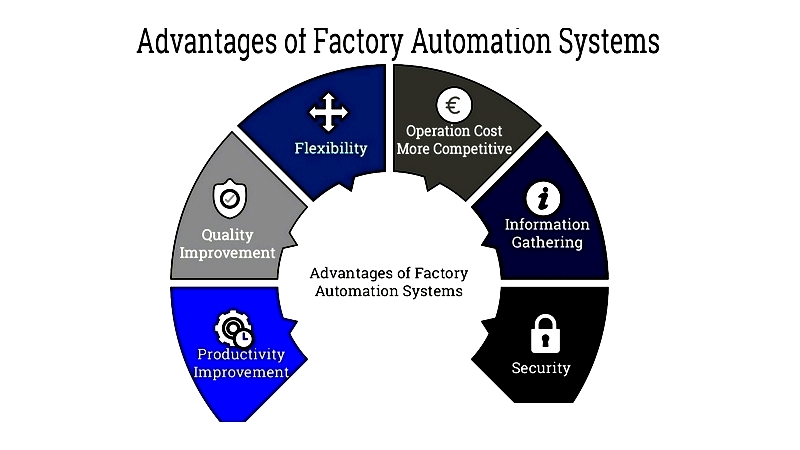

The rapid growth of factory automation is driven by intensifying global market competition. To maintain competitiveness, businesses are adopting automation to optimize operations, reduce costs, and boost productivity. Factory automation enables continuous 24/7 production with minimal errors, reduced waste, and superior product quality.

Factory automation encompasses comprehensive technology systems controlled by distributed control systems (DCS) or supervisory control and data acquisition (SCADA) systems. Programmable logic controllers (PLCs) and remote terminal units (RTUs) positioned throughout factories receive signals to direct equipment in performing tasks. These components are customized to meet specific product and process requirements. Key elements of factory automation systems include PLCs, advanced solutions, cybersecurity measures, and operational technology (OT), all integrated to effectively oversee and manage factory operations.

Chapter 2: Varieties of Factory Automation

Factory automation plays a crucial role in modern industrial manufacturing and smart factory operations. As manufacturing processes evolve, automation helps facilities improve efficiency, productivity, and product quality while lowering operational costs. Defining factory automation is complex due to its diverse applications across industries, from automotive manufacturing to pharmaceuticals. Each automation system is tailored to specific product needs and production environments, utilizing technologies like robotics, industrial control systems, PLCs, and artificial intelligence (AI).

Automation often brings to mind autonomous machines and industrial robots working seamlessly for mass production. While this may seem futuristic, advancements in automation engineering, machine vision, and industrial IoT have made this a reality for many manufacturers. Today's factory automation systems lead Industry 4.0, transforming industrial manufacturing through data-driven, interconnected, and self-optimizing solutions.

Factory automation systems range from those requiring significant human-machine interaction to fully autonomous solutions with minimal human involvement. Many plants deploy collaborative robots (cobots) that work safely alongside humans, combining human skills with automated precision and speed. The choice between automated and manual processes depends on throughput requirements, product variability, quality standards, and scalability.

Driven by advancements in robotics, machine learning, and cloud-based monitoring, automation technology is revolutionizing factories worldwide. The global factory automation market is expected to reach $400 billion by 2030, reflecting widespread adoption across industries seeking to optimize production, workplace safety, and resource utilization.

There are four main types of factory automation systems: fixed, programmable, flexible, and integrated. These categories differ in production volume, workflow flexibility, system complexity, programming capabilities, and human involvement. Understanding each type's strengths and applications helps manufacturers select the optimal system for their operational goals.

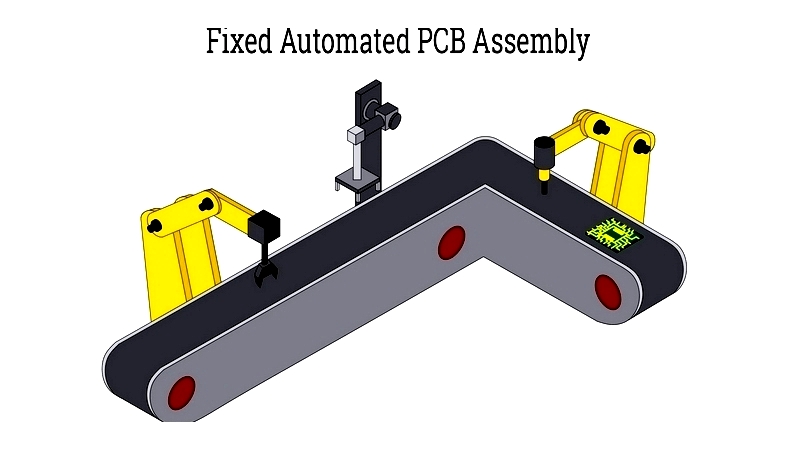

Fixed Automation

Fixed automation, or hard automation, is used for high-volume production of single products. These systems are designed for dedicated processes like repetitive assembly line operations with minimal variability. once configured, fixed automation systems cannot be easily reprogrammed for other products. The substantial initial investment makes them cost-effective only for large-scale, predictable demand. Common in automotive and electronics manufacturing, these systems offer durability and high throughput.

Despite their inflexibility, fixed automation employs advanced technologies like machine vision and custom tool integration for consistent, high-precision output. The costs are typically amortized over their long operational lifespan, making them ideal for lean manufacturing environments focused on continuous output.

Examples of Fixed Automation Systems

- Automated Assembly

- Web Handling

- Converting Systems

- Chemical Processes

- Conveyor Systems

- Transfer Lines

- Paint Processes

- Coating Processes

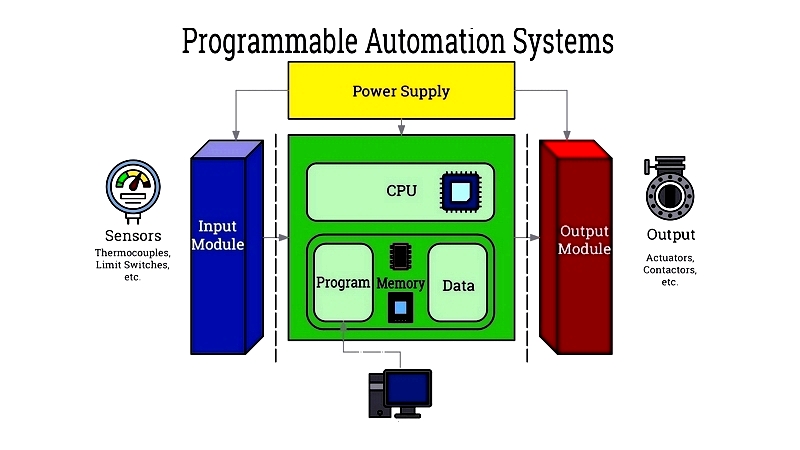

Programmable Automation Systems

Programmable automation allows manufacturers to switch between products by updating system instructions. Often using CNC machines, PLCs, and industrial robots, it supports batch manufacturing and mid-volume production. This flexibility benefits industries with variable demand or customization needs, such as electronics and aerospace.

Reconfiguring production lines involves simply modifying software programs, eliminating manual tooling changes. These systems excel at producing small to medium batches, supporting agile manufacturing strategies. While initial costs and technical expertise may be barriers, programmable automation reduces labor costs, increases consistency, and minimizes downtime during product transitions.

Key examples include CNC machining centers, robotic welding cells, pick-and-place robots, and AGVs. Modern programmable automation often incorporates IoT sensors and MES for real-time monitoring and optimization.

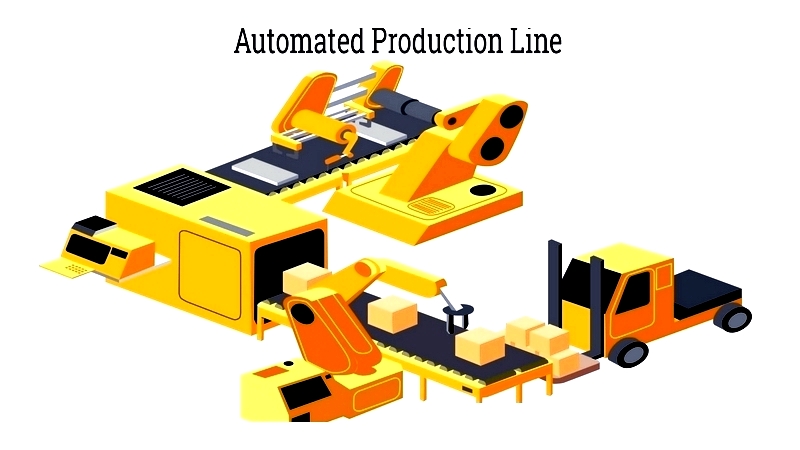

Automation Production Lines

Automated production lines enable high-speed, repeatable manufacturing through interconnected workstations. Similar to Henry Ford's innovations, today's lines use conveyors or robotic transporters to move parts between work cells. Each station performs specific tasks in sequence, using smart controllers and PLCs for precision.

These lines are widely used in automotive, electronics, and packaging industries. While humans may monitor processes or conduct quality checks, automation handles repetitive tasks. Enhanced by sensors and data analytics, modern lines support predictive maintenance, improve equipment effectiveness, and reduce defects.

End-to-End Automation (E2E)

End-to-end automation covers the entire manufacturing process from raw materials to final packaging. Enabled by interconnected hardware and software, including ERP and SCADA, it allows lights-out factories operating continuously with minimal supervision. Such systems boost productivity, reduce errors, enhance traceability, and create resilient supply chains.

As Industry 4.0 advances, E2E automation leverages robotics, AI-powered quality control, and predictive analytics. Solutions may include automated material handling, RPA, machine learning, and AMRs. Successful implementation requires robust OT and IT architecture, often paired with lean manufacturing and Six Sigma methodologies.

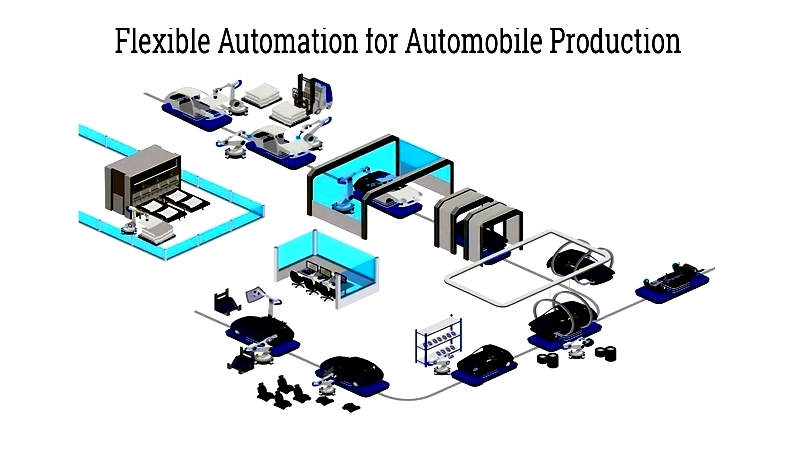

Flexible Automation (FA)

Flexible automation adapts quickly to changing production needs, supporting high-mix, low-volume manufacturing. Unlike fixed automation, flexible systems accommodate frequent changeovers with minimal downtime using programmable technologies and robotic arms. FA bridges programmable and integrated automation, allowing equipment and software reconfiguration for customized orders.

Valuable in automotive, electronics, and medical device industries, FA optimizes throughput while maintaining quality. Robots and CNC machinery can be quickly retasked, enabling rapid, cost-effective product launches. FA also supports rapid prototyping and mass personalization trends.

Integrated Automation

Integrated automation, or Computer-Integrated Manufacturing (CIM), connects all manufacturing operations into a seamless digital ecosystem. Combining industrial robotics, automated inspection, and real-time analytics, it enables continuous improvement and process optimization. Components include DCS, IIoT sensors, and MES platforms, synchronizing all automation assets.

These solutions minimize errors, reduce manual interventions, and accelerate time-to-market. Supporting digital transformation and smart manufacturing, integrated automation ensures reliability, security, and predictive decision-making across operations.