Introduction

This article provides an in-depth exploration of push button switches.

Key topics covered include:

- Principles of Push Button Switches

- Push Button Switch Design and Customization

- Types of Push Button Switches

- Applications, Benefits, and Drawbacks of Push Button Switches

- And more...

Chapter 1: Understanding the Principles of Push Button Switches

This chapter examines the functions and mechanisms of push button switches.

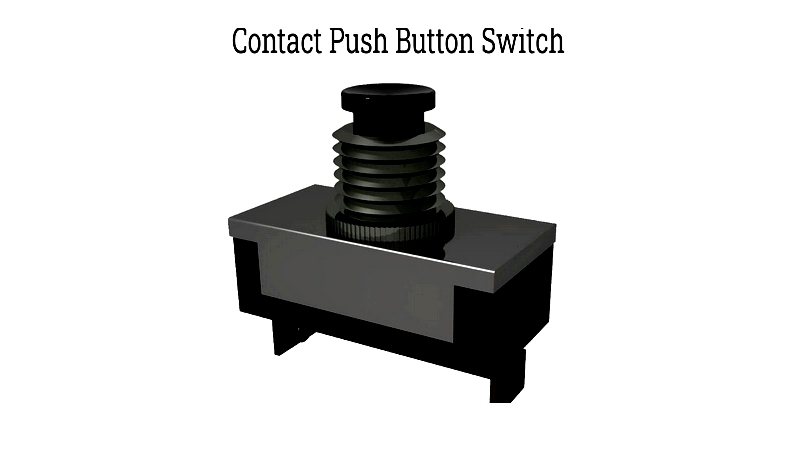

What Are Push Button Switches?

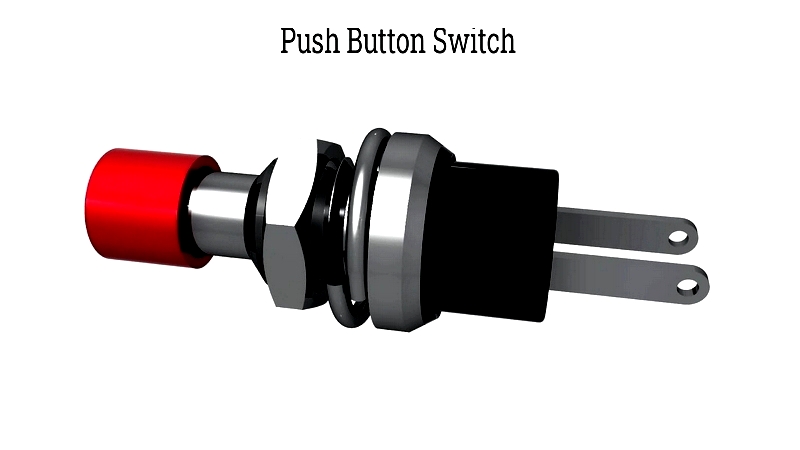

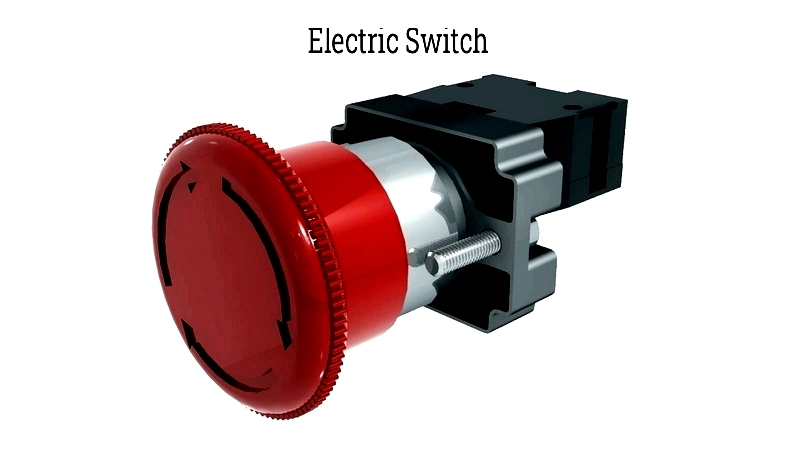

Push button switches, also known as pushbutton switches, are devices that establish or interrupt circuit connections when pressed. They are commonly used to control various electronic systems and devices.

These switches come in different designs, including keys and buttons, and are classified as either momentary or maintained. The most common momentary switch is the push button. A normally closed push button (push-to-break) disconnects the circuit when pressed, while a normally open push button (push-to-make) completes the circuit when pressed.

Maintained push button switches remain in position until pressed again, toggling between locked and released states. While most have two states, some configurations offer more. These switches are vital in numerous applications, from computers and traffic signals to industrial equipment, security systems, ATMs, military hardware, gaming machines, and fitness equipment.

How Push Button Switches Work

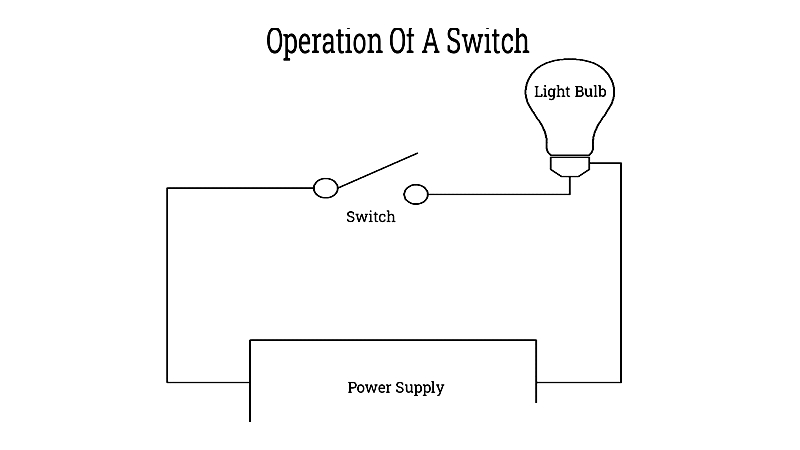

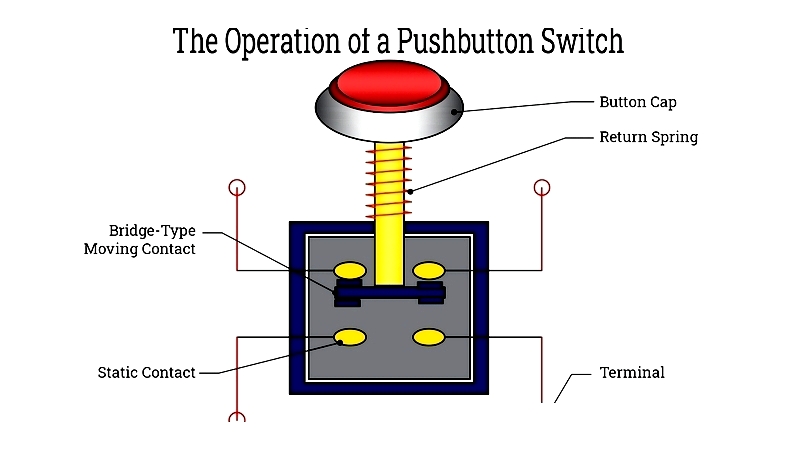

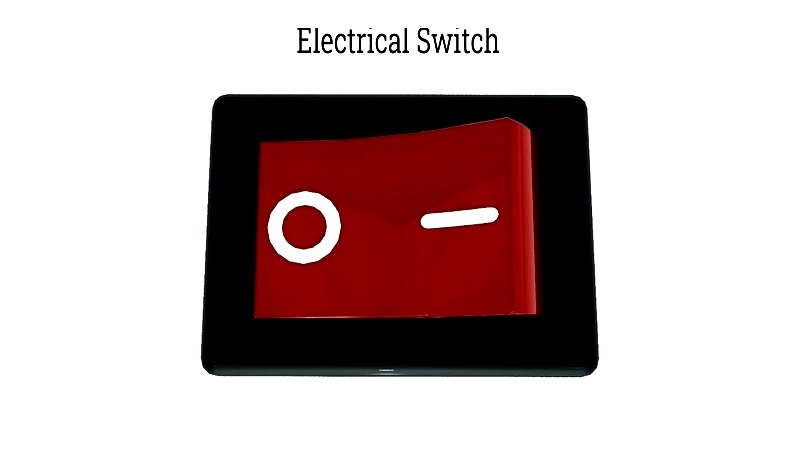

Like other electrical switches, push button switches modify their connected circuits. An open circuit blocks current flow, while a closed circuit allows electricity to pass. Some switches maintain circuit closure temporarily, while others do so permanently. Spring-loaded switches return to their open state when released.

Brief circuit interruptions can redirect power. Switches with sustained current flow feature distinct on/off positions that toggle with each press. Push buttons are essential for controlling electrical current, effectively conducting and interrupting energy as needed. Typically, circuit interruption involves creating an air gap between contacts that must separate quickly.

Switch resistance can be adjusted—high for open circuits, low for closed circuits. Most push button switches have few moving parts. Their responsiveness to the actuator, whether manual or automatic, is crucial. The actuator changes the connection state to enable or disable the circuit.

Actuation can occur through physical movement (levers, slides) or other stimuli (overvoltage, light changes). Many switches include protective fuses. Different electronic devices require varied circuitry solutions—from simple light bulb setups to complex computer keyboard circuits. Regardless of complexity, switches remain fundamental for circuit control.

Chapter 2: Push Button Switch Design and Customization

As fundamental electrical components, push button switches share basic functionality with toggle switches. Both are user-friendly, with push buttons requiring a press for operation. Many provide tactile feedback to confirm activation. Their reliability and versatility make them suitable for industrial panels, consumer electronics, automotive dashboards, and machinery interfaces.

Push button switches come in flush, recessed, or elevated designs. Recessed buttons prevent accidental activation, flush switches offer sleek integration, and elevated buttons enhance accessibility. Custom options include color variations, LED indicators, and engraved symbols for improved usability across different environments.

Key Design Features and Customization Options

Design considerations focus on application-specific requirements. Customization options include:

- Functionality: Momentary (spring-return) or maintained (toggle) operation

- Contact Configuration: SPST, DPDT, and multi-pole variants

- Environmental Protection: Waterproof, dustproof designs with IP ratings

- Visual Indicators: LED backlighting for status feedback

- Terminal Types: Solder, quick-connect, and screw terminals

Selection criteria include actuation force, cycle life, mounting style, and compliance with safety standards like RoHS or UL.

Relays in Electric Switches

Relays are electrically operated switches that control circuits using low-power signals. An electromagnetic coil activates a metal contact to change circuit connections. When de-energized, the contact returns to its default position. Latching relays maintain state without continuous power, making them suitable for applications requiring sustained circuit states.

Solid-state relays use semiconductors instead of electromagnetics, offering faster switching and longer lifespan. Optocouplers, combining LEDs with photodiodes, exemplify this technology. Growing automation and IoT demands continue to drive relay innovation.

Actuator Mechanisms

Actuators manually control switch operation. In push button switches, they open and close circuits. Modern designs balance ergonomics with reliability for industrial, commercial, and residential use.

Common actuator types include:

- Toggle: Lever-operated switches

- Rotary: Handle-turned controls, now common in precision equipment

- Biased: Spring-based mechanisms

Specialized actuators like piezoelectric and capacitive types support touch-sensitive applications in medical and consumer devices.

Connectors and Contactors in Electric Switches

Contactors function as heavy-duty switches, making and breaking electrical connections. Industrial models control motors and machinery, ensuring reliable operation.

Common contactor materials include:

- Copper/Alloys: Brass for general applications

- Silver/Alloys: High conductivity with oxidation resistance

- Gold: Corrosion-resistant but costly

- Platinum: Specialized uses

- Carbon: Nonmetallic conductor

Material selection impacts performance, safety, and longevity. Application environment and electrical load requirements guide proper switch selection.