Introduction

This article covers everything you need to know about J extrusions and their applications.

You will learn about:

- What J Extrusions are

- Their common uses

- Manufacturing processes

- Materials used in production

- And more...

Chapter 1: Understanding J Extrusions

J extrusions are trim pieces shaped like the letter "J." They create clean edges that direct water flow while providing a professional finish. The name comes from their design - a flat base with two curved sides, where the longer leg forms the J shape. This extended leg allows secure attachment to walls or panels, often featuring slots or holes for nails or screws.

Also called J channels, these extrusions serve various trimming purposes. Their shape can be customized to fit specific edges or trim requirements.

Manufacturers make them from extrudable materials like aluminum, steel, and plastic. These materials provide durability, making them effective protective barriers. Since they're often used outdoors, J channels typically receive protective coatings like baked-on paint or powder finishes.

Chapter 2: Types of J Extrusions

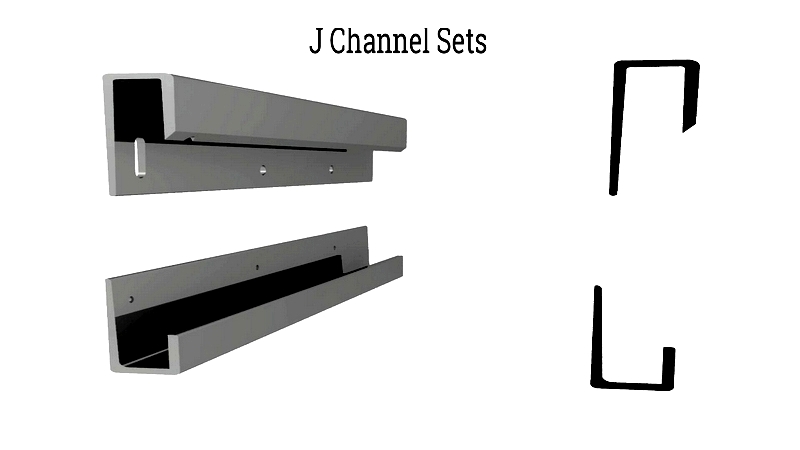

J extrusions, commonly called J channels in construction, come in various types designed for specific applications. These metal profiles feature different leg lengths and bottom widths to suit installation needs. They're widely used as trim components, edge protectors, and finishing elements in buildings. The three main types include unhemmed, hemmed, and versions with integrated nailers. Choosing the right type ensures proper function for siding, paneling, or framing projects.

Indented J Channel

Indented J channels have a specially designed back on their longer leg. This creates space to hold displays, glass panels, or mirrors slightly away from walls, allowing airflow and reducing moisture. They're particularly useful for interior displays and shower enclosures, where the recess provides extra grip for heavy panels.

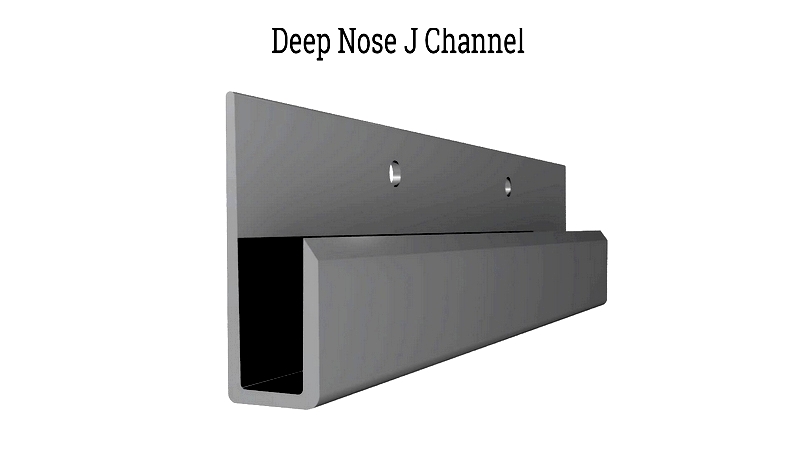

Deep Nose J Channel

These feature an extended front leg that accommodates uneven surfaces. Made from aluminum, stainless steel, or galvanized steel, they offer stability and protection. Their design makes them ideal for mounting mirrors, glass, and wall panels in commercial spaces.

The extended "nose" provides extra support for large, thin surfaces, making them valuable for drywall termination and panel installation.

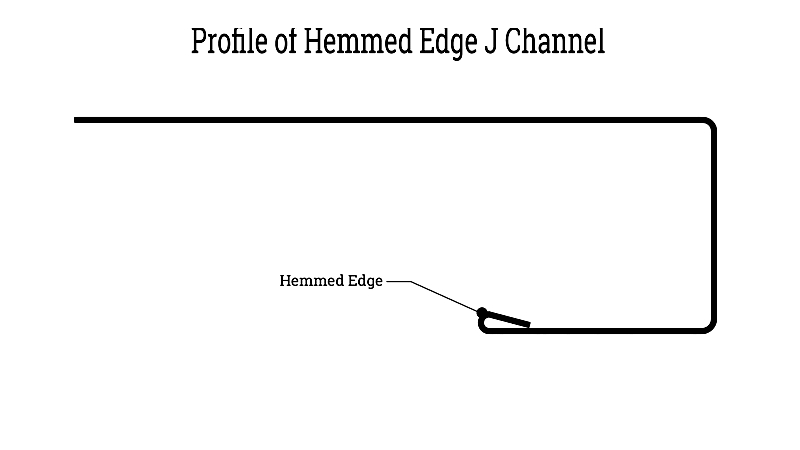

Hemmed J Channels

These have a rolled edge created by folding the leg over itself. This eliminates sharp edges, making them safer to handle and reducing surface damage risk. Architects often specify them for visible areas like window trim where a clean finish is important.

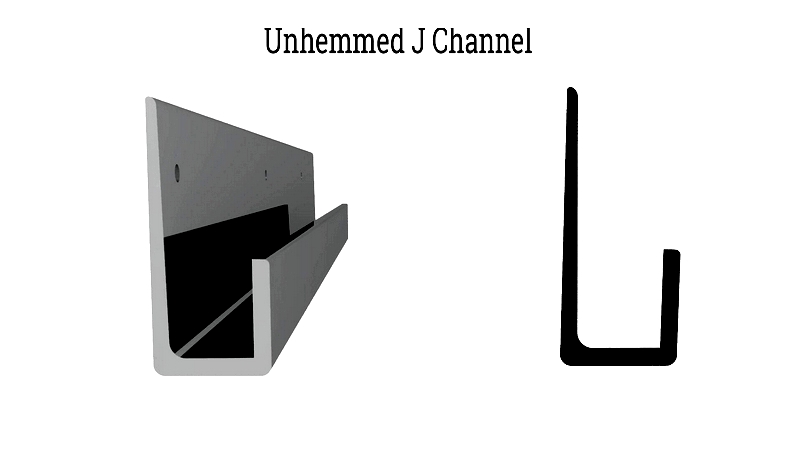

Unhemmed J Channels

The standard version with straight legs, suitable for general use. Available in various sizes, they work well for base trim, edge protection, and transitions. Coatings can be added for durability and color matching.

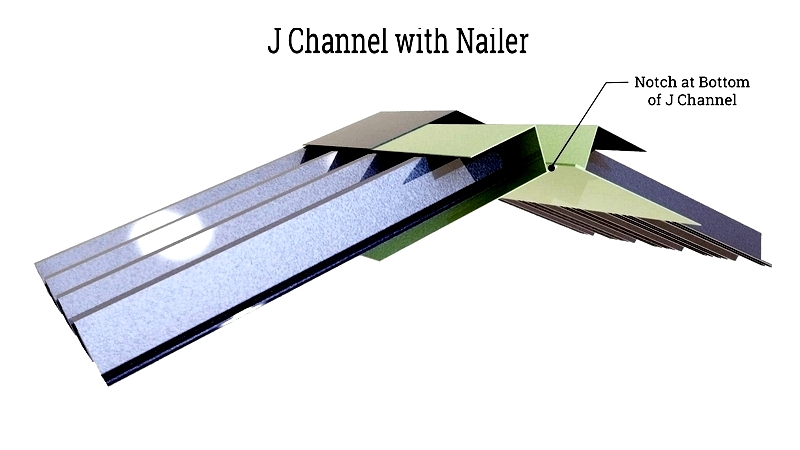

J Channel with Nailer

Designed for roofing and siding systems, these feature an extended leg that forms a notch for secure fastening. They provide stable mounting for panels in demanding weather conditions.

These represent just some available options. Modern J extrusions come in various sizes, finishes, and materials. Consider your project's requirements when selecting the right type.

For help choosing J channels or custom profiles, consult a reputable supplier or visit our resource page.

Chapter 3: Manufacturing J Extrusions

J extrusions are made through aluminum extrusion processes that ensure precision and quality. While available in plastics and steel, aluminum is preferred for its lightweight durability and corrosion resistance.

J Channel Extrusion

The process involves pushing heated aluminum through a J-shaped die. This method produces accurate, uniform profiles for construction and industrial uses.

Types of Aluminum Used

Common alloys include 6063 and 6061, valued for strength and corrosion resistance. These work well for windows, doors, and industrial applications.

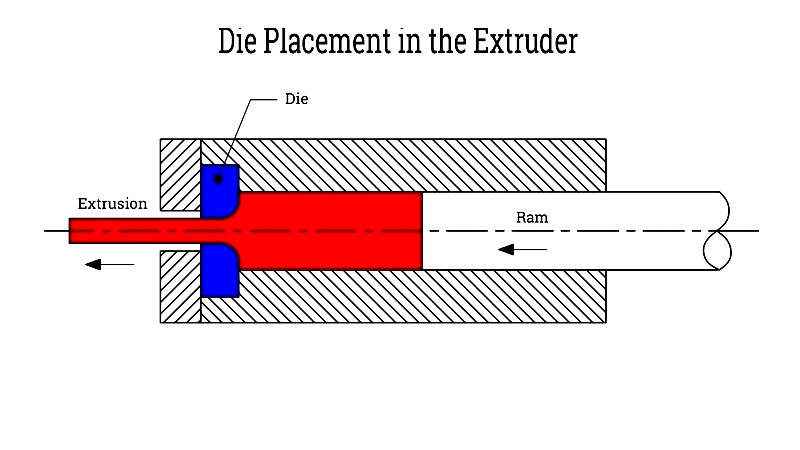

Extrusion Dies

Precision dies shape the aluminum into J profiles. Proper die design and maintenance ensure consistent quality.

Preparing the Die

Dies are preheated to 450-500°C before extrusion to ensure smooth material flow and product consistency.

Heating the Billet

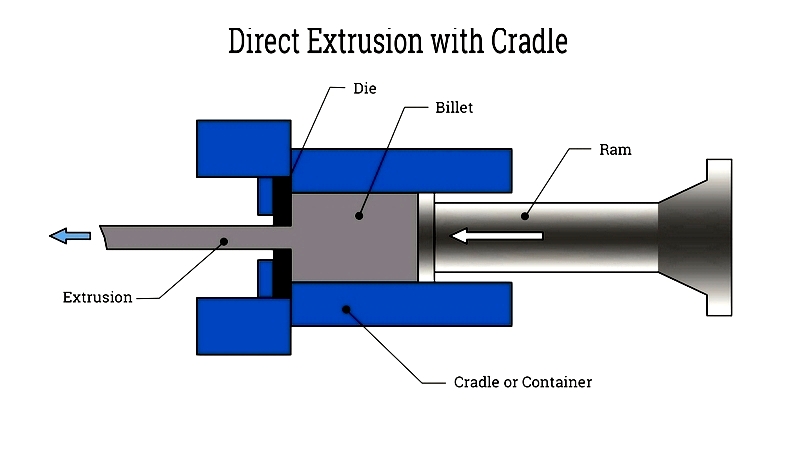

Aluminum billets are heated to optimal temperatures for shaping without melting, ensuring proper form and strength.

The Extrusion Process

A hydraulic ram forces the billet through the die. Direct extrusion is most common for J channel production.

Cooling

After exiting the die, profiles are quickly cooled to stabilize their properties and prevent distortion.

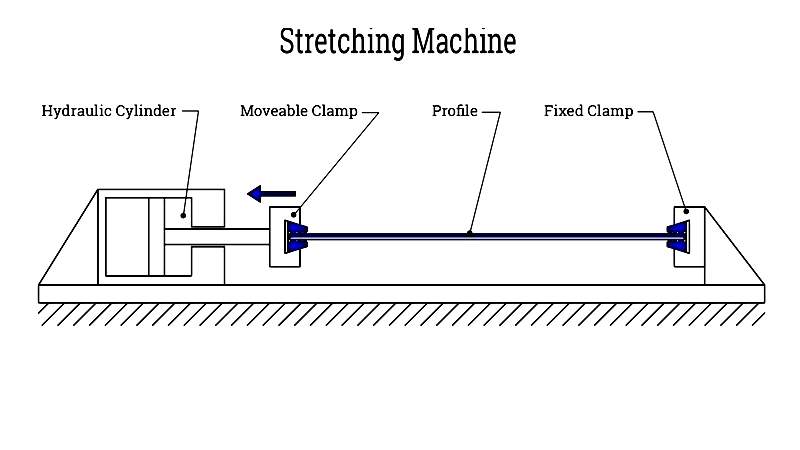

Cutting and Stretching

Extrusions are cut to length and stretched to correct any bending from the process.

Finishing

Final steps may include heat treatment, coating, or machining to meet specific requirements.

When sourcing J extrusions, consider alloy, finish, and intended use. Consulting manufacturers can help select the best product for your needs.