Introduction

This article provides an in-depth exploration of metal finishing types.

Key topics covered include:

- Principles of metal Finishing

- metal Finishing Process Types

- Applications and Benefits of metal Finishing

- Additional important Information

Chapter 1: metal Finishing Principles

This chapter explores metal finishing and its various processes.

Understanding metal Finishing

metal finishing encompasses techniques that apply protective coatings to metal surfaces. These processes include cleaning, polishing, and treatments that enhance metal product quality. Methods like electroplating and electroless plating provide benefits such as corrosion resistance and increased strength.

Electroplating uses electrical current to deposit metal ions onto substrates. Though distinct, it shares objectives with other finishing techniques.

The plating process applies metal electrostatically to conductive surfaces, representing modern finishing methods. Finishing broadly refers to processes that improve both appearance and functionality of metal items used in various settings.

Raw metal appears rough and unappealing. To enhance utility, it requires polishing, finishing, and transformation. metal finishing is crucial in metalworking.

Final finishing techniques improve visual appeal while reducing wear, extending lifespan and aesthetic value.

Finishing enhances material properties including electrical/chemical resistance, durability, and vulcanization. Beyond aesthetics, it improves industrial performance by increasing torque resistance and facilitating soldering.

Corrosion prevention is essential for all metals. Finishing reduces corrosion risks and prepares surfaces for painting. Comprehensive finishing minimizes cleaning needs by addressing surface defects. Manufacturers use various techniques to ensure product durability, making finishing vital for quality metal production.

Selecting Finishing Methods

Choosing appropriate finishing techniques is critical in manufacturing. Each method offers unique treatments for specific surface characteristics.

Finishing techniques include mechanical surface modifications. Careful selection is necessary as each method provides distinct advantages.

Finishing achieves desired appearance and texture while meeting design specifications and preventing rust. It improves strength, thickness, durability, and hardness.

Method selection impacts product value. Considerations include costs for water, coatings, energy, labor, and waste management.

Beyond direct costs, equipment maintenance expenses must be evaluated. metal type influences method choice, requiring thorough assessment for profitability. Processing time affects delivery schedules and supply chain efficiency.

While electroplating takes time, alternatives like buffing offer faster solutions, impacting delivery timelines and supply chain performance.

Chapter 2: metal Finishing Process Types

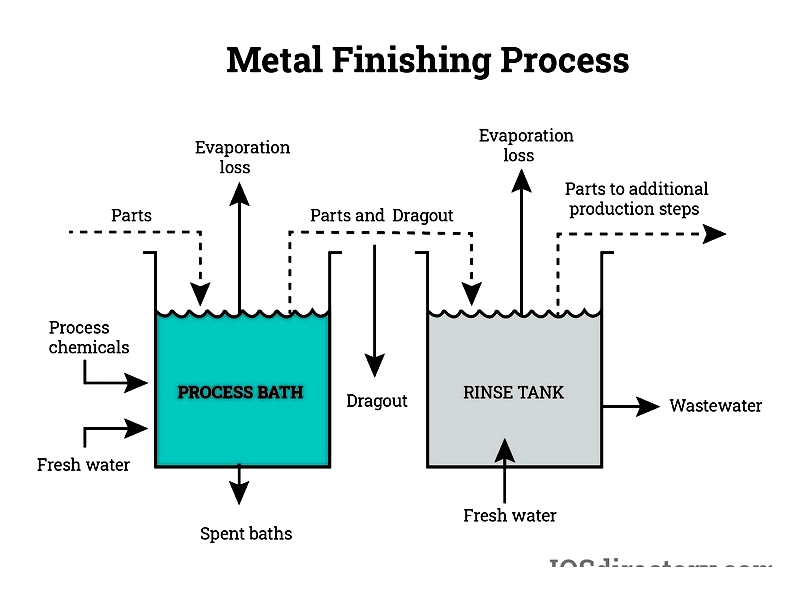

metal finishing is essential for product durability, performance, and aesthetics. Processes include plating, chemical coating, grinding, buffing, electroplating, and sandblasting. Modern finishing is crucial for automotive, aerospace, electronics, and construction industries, providing corrosion resistance and surface protection. All processes begin with surface preparation, which significantly impacts quality and lifespan.

Finishing ranges from advanced electroplating to simple polishing. Method selection depends on desired finish, environmental resistance, part geometry, and application. Understanding these processes helps engineers select optimal solutions balancing cost, efficiency, and performance.

Surface Preparation

Successful metal surface finishing requires proper preparation. Inadequate preparation leads to coating failures like flaking or corrosion. Initial cleaning uses chemicals, degreasers, or dry cloths. Light sanding may remove gloss or contaminants for better coating adhesion.

Inspecting for rust is crucial as it affects appearance and structure. Rust removal methods include sanding, wire brushing, or chemical treatments.

Surface Preparation Steps

- Disassembly – Necessary for complex multi-part objects to ensure complete finishing.

- Stripping - Removes excess material without damaging workpieces using various chemicals.

- Polishing – Smooths surfaces and removes oxidation using buffers or polishing wheels.

- Cleaning – Eliminates contaminants using solvents, aqueous cleaners, or rinsing.

Proper pretreatment ensures optimal paint adhesion, reduces defects, and enhances long-term corrosion protection for decorative or protective coatings.

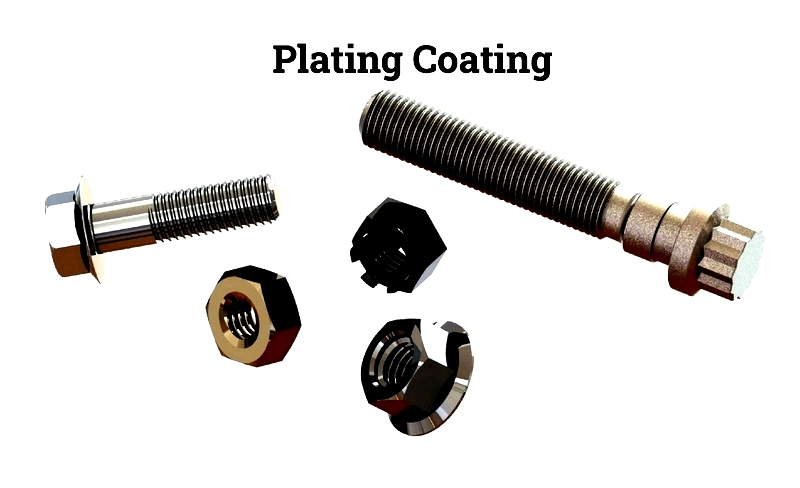

Plating

Plating deposits metal layers on conductive substrates. Widely used in electronics and automotive industries, it enhances appearance and provides wear/chemical resistance. Processes include electroplating and electroless plating, modifying surface conductivity and improving properties like solderability.

Plating involves pretreatment, setup, plating, and post-treatment. Common plating metals include zinc, copper, gold, and nickel.

Additional methods include immersion, PVD, and plasma spray coating. Plating services are customized for thickness, finish, and end-use environment.

Plating metal Types

Plating enhances metal strength and lifespan. Selection depends on desired functionality, whether aesthetic or performance-oriented.

Chrome Plating - Uses chromium compounds to apply chrome layers. Hard chrome plating provides exceptional wear resistance for industrial components.

Hard Chrome Plating - Deposits chrome layers (2-250µ) using chromic acid solutions. Offers low friction and excellent abrasion/corrosion resistance.

Nickel Plating - Electroless nickel-phosphorus alloy plating (2-14% phosphorus) increases hardness and corrosion resistance for harsh environments.

Teflon (PTFE) Plating - Combines nickel with PTFE for non-stick, low-friction coatings used in food processing equipment.

Tin Plating - Provides non-toxic, corrosion-resistant coatings through electrodeposition or hot dipping, ideal for electronics.

Zinc Plating - Electro-galvanization process that prevents steel oxidation, commonly used for automotive fasteners.

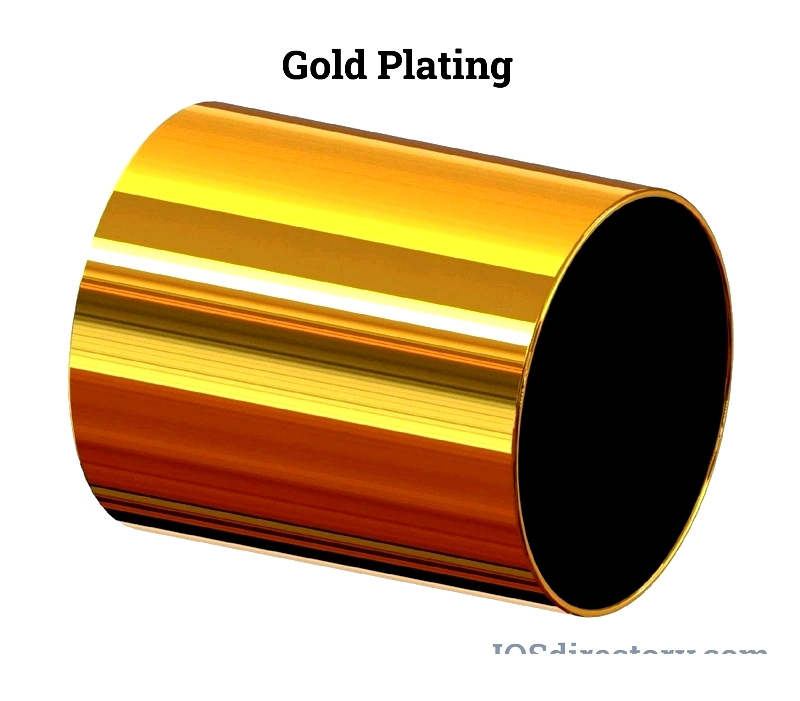

Gold Plating - Applies thin gold layers for exceptional conductivity and tarnish resistance in electronics and decorative applications.

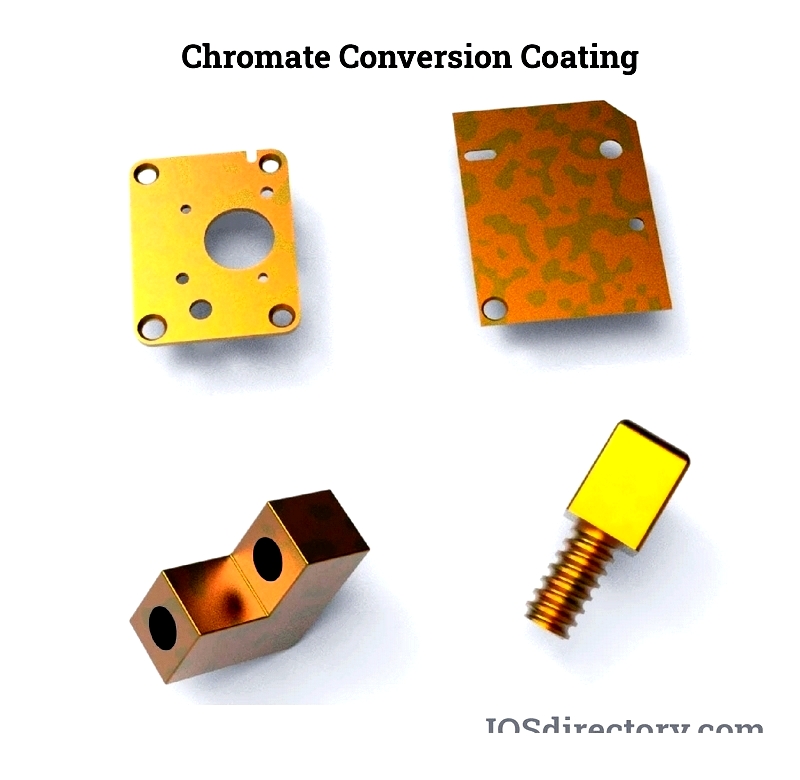

Conversion Coating

Conversion coating modifies metal surfaces to create protective oxide/phosphate layers. Processes use acidic baths or electrical treatments for corrosion protection. Examples include chromate, phosphate, and black oxide. Anodizing is a specialized conversion coating for aluminum.

Unlike plating, conversion coating alters existing surfaces to improve paint adhesion. It integrates with the metal, providing enhanced protection crucial for aerospace and electronics industries.

Conversion Coating Materials

Alodine Coating - Chromate-based coating (0.25-1µm) protects aluminum while maintaining conductivity for aerospace applications.

Black Oxide Coating - Creates matte black finishes through chemical treatment, improving appearance and providing moderate corrosion resistance when oiled.

Electroplating

Electroplating uses electric current to deposit metal ions onto workpieces. The process involves an anode, cathode, electrolytic solution,