Introduction

This article provides an in-depth exploration of electric heaters.

You will learn about topics such as:

- Why choose an electric heater?

- How electric heaters work

- Selecting the right electric space heater

- Different types of electric heaters

Why Use an Electric Heater?

While many consider electric heaters unnecessary in modern buildings with central heating, they actually offer energy-efficient warmth. These heaters complement central systems by providing targeted comfort while reducing energy consumption. Their primary benefit is potential cost savings on heating bills.

When temperatures aren't cold enough to trigger central heating, electric heaters create a cozy environment where extra clothing might be impractical. They're particularly useful for individual comfort during work or leisure activities.

For single occupants, electric heaters can be more economical than running whole-house systems. Their portability makes them ideal for home offices, bedrooms, or kitchens. Modern designs are lightweight and easily moved between spaces.

According to the U.S. Department of Energy, heating and cooling account for over half of electricity costs. Using electric heaters strategically can reduce these expenses. While an electric furnace might cost $1800 annually, heating a single room with an electric heater during winter months could cost about $315 at $0.12 per kilowatt hour.

Climate affects electric heater effectiveness. In mild regions like California, they're rarely needed, but in colder states like Minnesota or North Dakota, they provide significant savings. Remember that electric heaters work best for individual rooms alongside central heating systems.

To maximize efficiency, combine electric heaters with central heating using smart practices. Key benefits include lower costs and enhanced comfort. Proper techniques ensure energy conservation and effective integration.

Programmable thermostats help reduce heating expenses by adjusting temperatures when rooms are unoccupied. The Department of Energy estimates lowering the thermostat 10-15 degrees during these times can save 5-15% on heating costs.

Another strategy involves lowering building temperatures while using electric heaters in occupied rooms. Identifying frequently used spaces and equipping them with suitable heaters makes this approach effective.

Electric heaters support environmental sustainability by heating specific areas without wasting energy. Unlike gas or oil systems, they produce no air pollution. Infrared models are especially eco-friendly.

How Electric Heaters Work

Electric heaters operate similarly to central heating systems but on a smaller scale. With numerous models available, careful selection ensures the best fit for your needs.

All heaters contain electrical resistors that convert electricity to heat. Resistance, often viewed negatively, is actually essential for heat generation. Higher resistance materials create more heat by impeding electrical current.

Resistors serve multiple functions: regulating current flow, maintaining voltage consistency, and providing surge protection. Their quality directly impacts heater efficiency and lifespan.

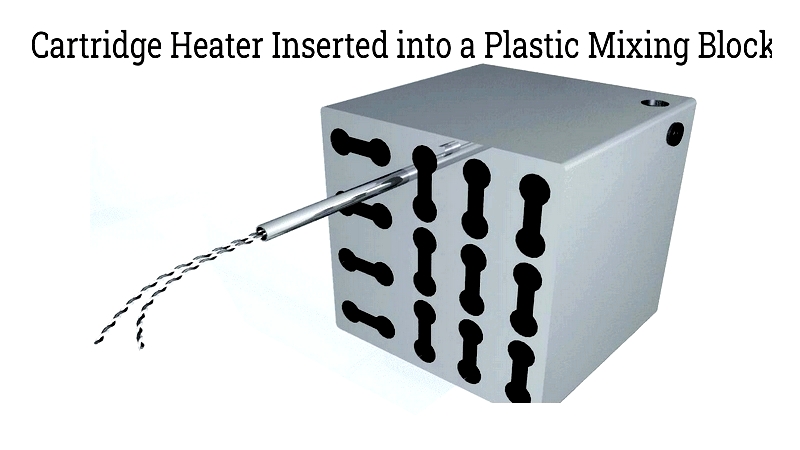

Various resistor types exist, including ceramic cylinders, mica-wrapped wires, and magnesium oxide-insulated models. Each offers distinct advantages for different applications and power requirements.

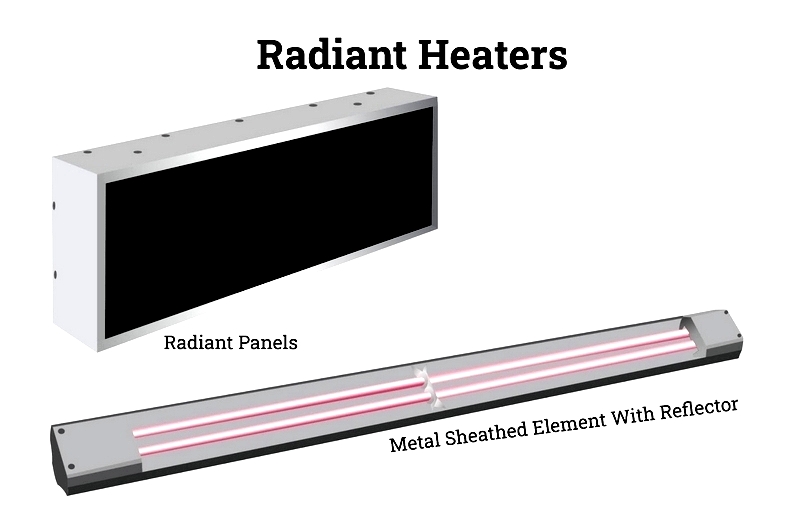

When activated, current heats the nichrome wire heating coil. Fans then circulate warm air through convection, similar to hair dryers. Fanless models use radiant heating, warming nearby air gradually - ideal for small spaces.

Electric heaters come with or without thermostats. Basic models have simple on/off switches, while advanced versions feature temperature controls that automatically maintain desired warmth. Most modern heaters include thermostats as standard features.

Choosing an Electric Space Heater

While older electric heaters earned poor reputations, modern versions offer significant improvements. Today's wide selection makes choosing more complex than in previous decades.

First determine your required heat output based on room size. Standard heaters typically cover 400 square feet, while powerful models reach 1,000 square feet. Proper measurement prevents buying unsuitable units.

Consider energy-saving features when evaluating options. Programmable timers and thermostats offer convenience and efficiency. Price generally reflects features - basic radiant heaters cost less than thermostat-equipped models.

Assessing noise levels can be challenging when shopping. online product listings often provide this information, which physical stores might lack. Generally, baseboard and radiant heaters operate most quietly without fans.

Making an informed electric heater purchase requires research. Careful consideration helps select energy-efficient models that reduce electricity costs. Utilize available resources to make smart buying decisions.