Introduction

This article provides an in-depth exploration of magnets.

It offers comprehensive insights into topics including:

- Principle of Magnets

- Types of Magnets

- Applications of Magnets

- And Much More...

Chapter 1: Understanding the Principle of Magnets

This chapter examines the fundamentals of magnets, including their manufacturing techniques and operational mechanisms.

Defining a Magnet

Magnets are objects that exert a distinctive force on other materials without physical contact. This magnetic force can attract or repel. While many substances display some magnetic properties, only a few generate sufficient force to be classified as magnets. The Earth itself functions as a massive magnet.

Magnets feature two regions where magnetic force is strongest, known as poles. These opposite poles are labeled the North Pole (north-seeking) and South Pole (south-seeking) on rectangular bar magnets.

Mechanism of Magnetism

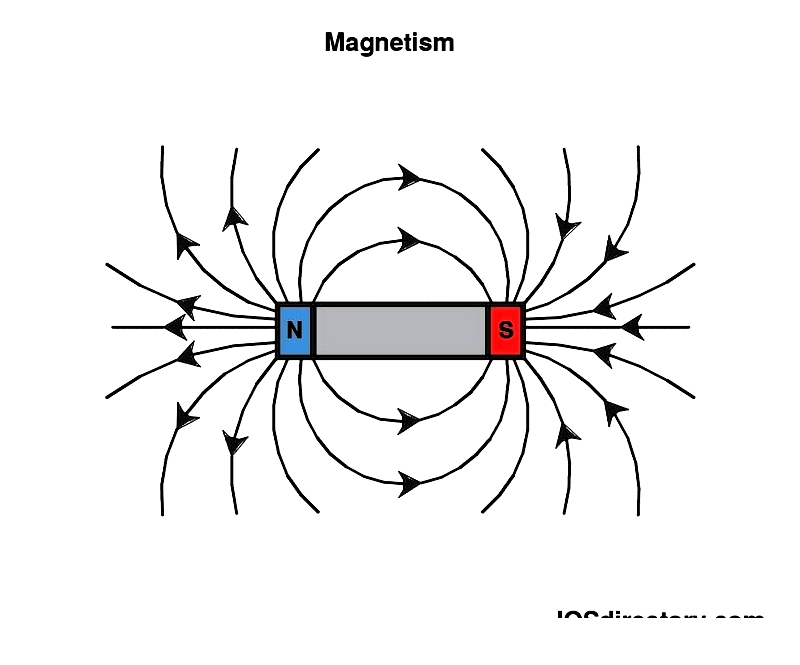

Magnetism originates from the behavior of tiny particles called electrons. All matter consists of atoms containing electrons, neutrons, and protons. As electrons orbit the nucleus, they create small magnetic fields. In certain materials, numerous electrons align their spins uniformly, producing a combined magnetic effect that manifests as a significant magnet.

Magnets can be created by rubbing metal with an existing magnet, using unidirectional motion to align electrons. Electric current also generates magnets. Since electricity involves electron flow, moving electrons in a wire produce a magnetic field similar to atomic electron spins. This type is called an electromagnet.

Nickel, cobalt, iron, and steel are ideal for permanent magnets due to their electron arrangement. once magnetized, these metals retain their properties indefinitely, known as hard magnets. Some metals show temporary magnetism near hard magnets, classifying them as soft magnets.

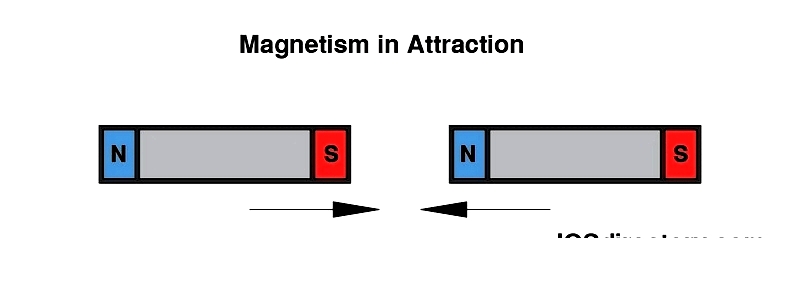

Most elements like wood or water exhibit weak magnetic properties. However, magnets strongly attract objects containing iron, nickel, or cobalt. They can also attract or repel other hard magnets because each has two opposing poles. Opposite poles attract, while like poles repel.

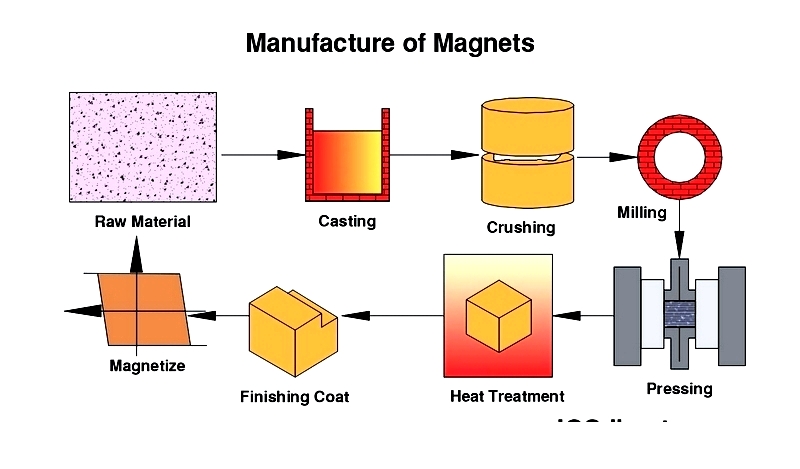

Magnetic Production Process

Magnets are commonly produced through powder metallurgy. Different types require varied manufacturing methods. Electromagnets use metal casting, while flexible magnets employ plastic extrusion - heating, blending, and forcing materials through an opening under pressure. Below is a general overview of magnet production.

Powder Preparation

Iron, boron, and neodymium are melted in an air-free furnace to prevent reactions. The cooled alloy is fragmented and pulverized into 3-7 micron powder. Since the powder is flammable when exposed to oxygen, it must remain air-sealed.

Compaction Procedure

Isostatic compaction places powdered metal into molds under magnetic alignment. Hydraulic pressure compresses the material near its final thickness, typically using 10,000-15,000 psi. For complex designs, powder is sealed in evacuated containers before gas pressure shaping.

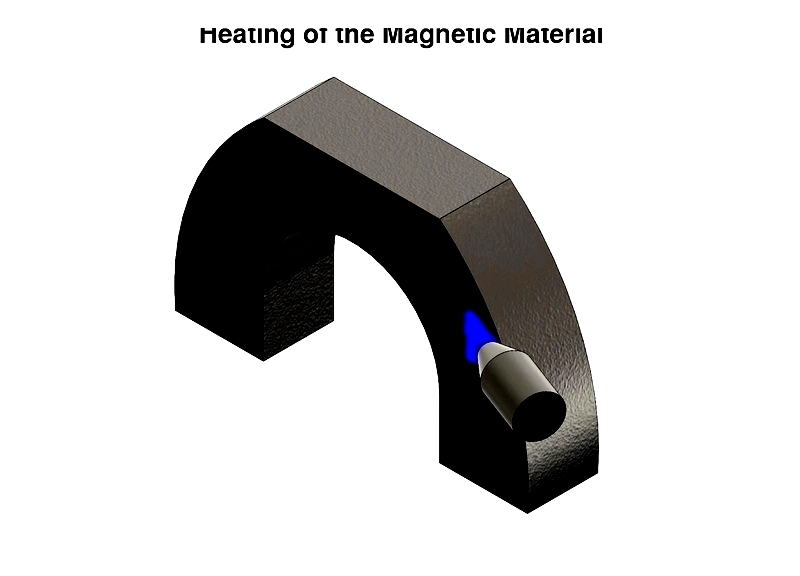

Material Heating

After compaction, powdered metal undergoes sintering in an oven. This three-stage process involves: removing moisture with low heat, bonding particles near melting temperature, and gradual cooling to complete sintering.

Annealing Process

Annealing follows heating, using controlled temperature cycles to relieve internal stresses and strengthen the material.

Finishing Magnets

Sintered magnets are typically machined - ground smooth or cut into segments. Their hardness requires diamond wheels for cutting/grinding. Precision cutting minimizes additional grinding, though care prevents cracking.

Shaped diamond wheels achieve "near net shape" dimensions. Final machining removes excess material before protective coating application.

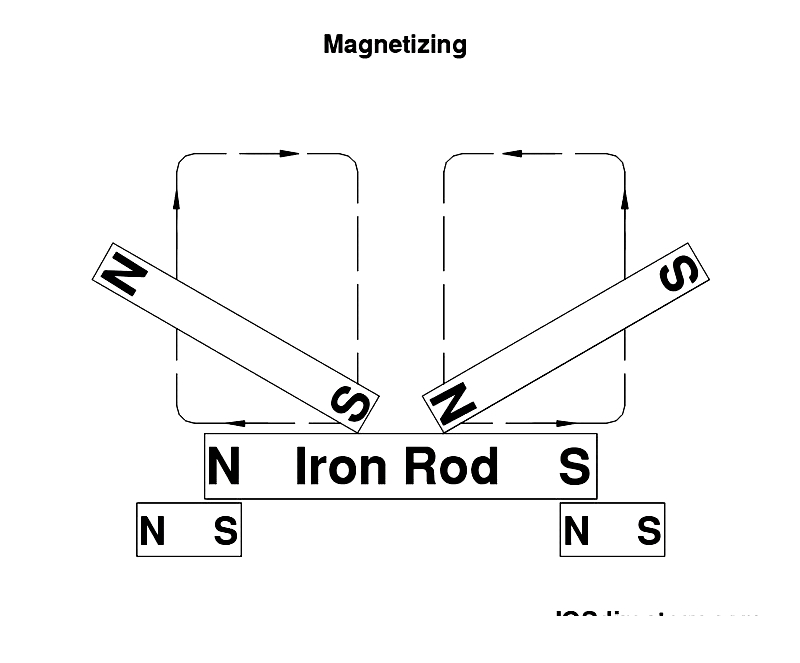

Magnetization Process

Finished magnets are magnetized using solenoids configured for various sizes/shapes. Large assemblies may be magnetized together to reduce handling charged units. Strong magnetizing fields are crucial here.

Material remains compressed metal until final manufacturing. Though isostatic pressing aligns powder, no magnetism occurs until electromagnet activation creates permanent magnets.

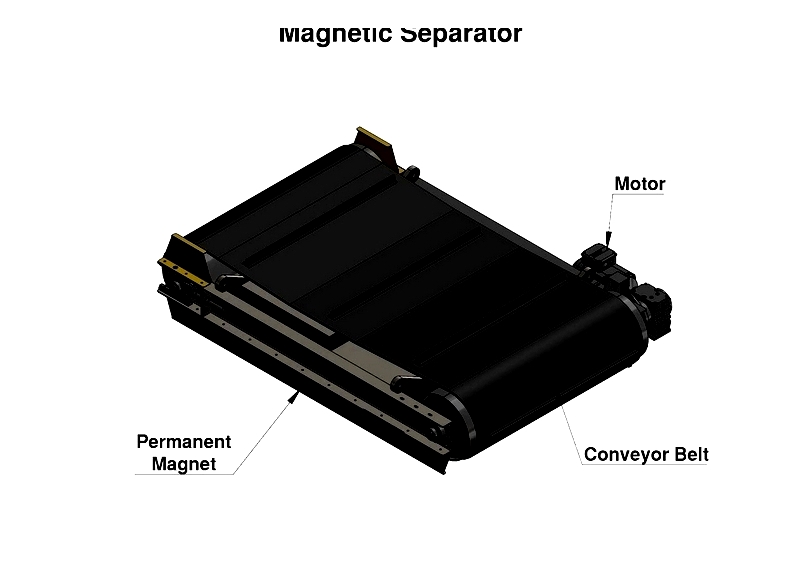

Magnetic Separation Method

This technique uses magnets to efficiently extract magnetic materials from mixtures. Effective for ferromagnetic minerals (cobalt, iron, nickel), it doesn't work for non-magnetic metals (silver, gold). Mechanical methods help isolate magnetic elements; separator drum magnets capture particles, forming concentrates.

Magnetic separation is vital for electromagnetic cranes in waste/shipping management, efficiently removing unwanted metals. Common in recycling, it purifies ores and removes impurities. Traditional tools include magnetic pulleys, overhead magnets, and drums.

Particularly useful in iron mining due to magnetic attraction. In food/pharmaceutical sectors, it eliminates metal contaminants, enhancing purity and recycling efficiency.

Chapter 2: Magnet Varieties

Magnets serve critical roles across industries and technologies. Understanding different types helps select optimal solutions for specific needs. Below we detail primary magnet categories - both permanent and temporary - including their properties, manufacturing, and applications. This knowledge proves valuable whether seeking industrial, rare earth, or specialty magnets for engineering/electronics.

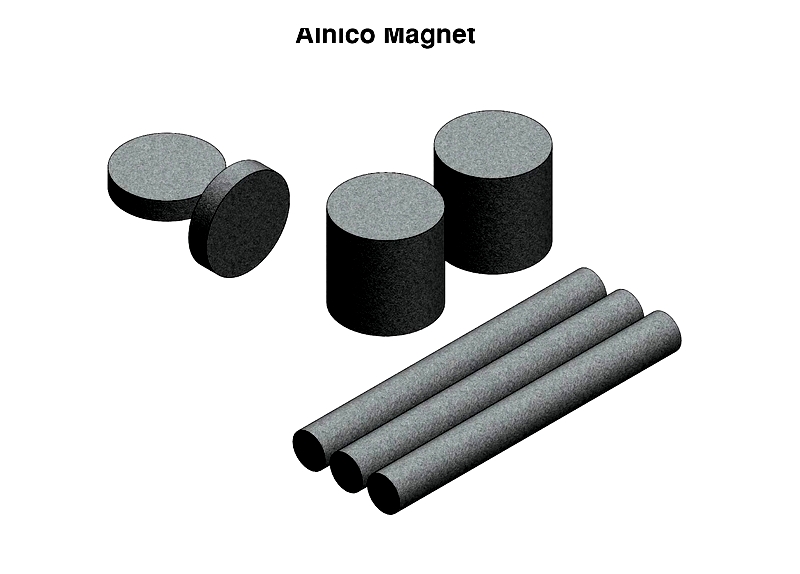

Alnico Magnets

Available in cast, sintered, and bonded forms (cast being most common), these permanent magnets contain nickel, aluminum, iron, cobalt, plus minor titanium/copper. Their high coercivity and stability stem from iron/cobalt particle shape anisotropy within a weakly ferromagnetic nickel-aluminum matrix. High-temperature tempering enhances durability for demanding environments.

Spinodal decomposition determines final particle sizes early. Alnicos boast excellent temperature coefficients, maintaining stable field output despite temperature fluctuations. They withstand higher temperatures than other magnets, ideal for industrial sensors and guitar pickups.

Demagnetization reduces with improved working points, like increased length-to-diameter ratios. All external factors must be considered though. Optimal performance often requires good magnetic circuits, especially in assemblies.

Bar Magnets

These rectangular steel/iron permanent magnets are classic educational tools featuring north/south poles. Freely suspended, they align with Earth's magnetic north, serving as simple compasses. They demonstrate magnetic fields/flux lines via iron filings.

Two main types exist: cylindrical (rod) magnets with strong magnetic properties from thick diameters, and rectangular versions preferred for manufacturing due to consistent fields. Broken pieces retain both poles (magnetic dipole). Force concentrates at poles, attracting ferromagnetic materials (cobalt, nickel, iron) for research, crafts, and small-scale separation.