Introduction

This article provides an in-depth exploration of aqueous part washers.

Key topics covered include:

- Working Principles of Aqueous Part Washers

- Varieties of Aqueous Part Washers

- Applications and Advantages of Aqueous Part Washers

- Safety Considerations for Aqueous Part Washers

- Additional relevant information

Chapter 1: Understanding Aqueous Part Washers

This chapter examines the fundamental concepts of aqueous part washers, including their design and operational principles.

What Are Aqueous Part Washers?

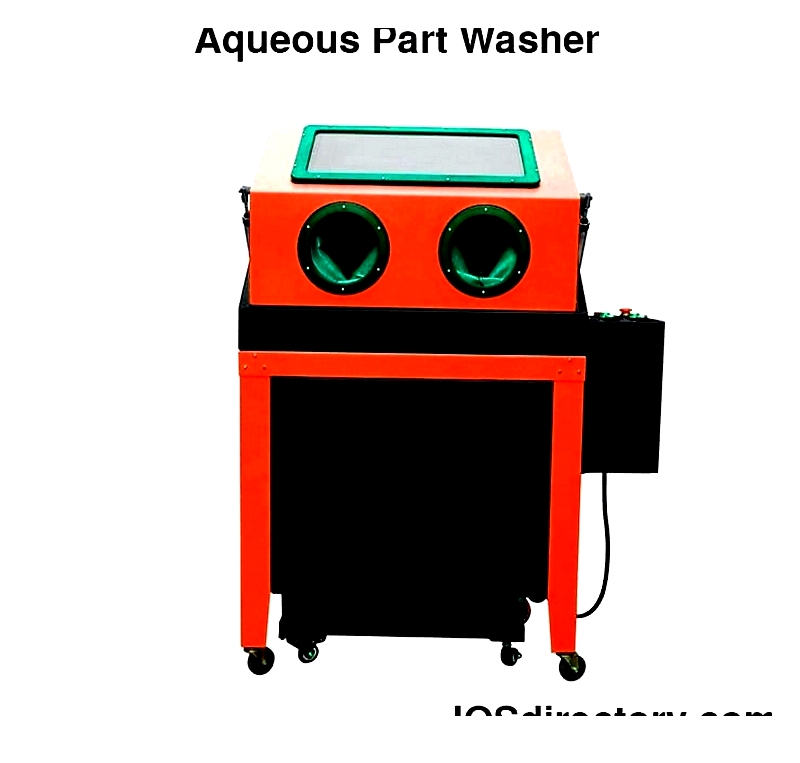

An aqueous part washer is a cleaning device, available in fully or semi-automated configurations, designed to thoroughly clean and remove stubborn grease from various sized components. These machines clean and dry parts, preparing them for shipping or further surface treatments.

Cleaning is essential as manufacturing processes often leave parts coated with chemicals, oils, and residues.

Design Features of Aqueous Part Washers

The basic design of aqueous part washers considers the size, shape, and configuration of parts to be cleaned. Other factors include weight distribution, surface area, and hidden cavities. Manufacturers often incorporate CNC programming, loading baskets, racks, trays, conveyor belts, and rotary tables in certain models.

Most parts washers use water-based solvents to immerse, boil, or spray-clean dirty components. Key components include water heaters, pumps, filtration systems, brushes, scrubbers, and enclosed cabinets.

Water Heater Components

The water heater is a crucial part of the cleaning system. It uses gas, steam, or electricity to heat cleaning solutions, accelerating the cleaning process. Higher temperatures enhance chemical reactions between solvents, detergents, and cleaning agents.

Filtration System Function

The filtration system cleans incoming water. During operation, cleaning agents flow from the cleaning tank to the storage tank through dual filters. The first filter captures large debris, while the second catches finer particles.

Parts Washer Pump Operation

The pump circulates cleaning solutions (solvent, water, or detergent) through the system. Operating continuously at high temperatures and flow rates, it moves solutions between tanks to ensure thorough cleaning. Inefficient pumping reduces cleaning effectiveness.

Scrubbers and Brushes

Scrubbers typically consist of sprayers or brush arrays. Cleaning solution is pumped from the tank to these components to aid the cleaning process.

Washer Cabinet Design

Washer cabinets come in various sizes and capacities to meet different cleaning needs. High-pressure aqueous solutions clean parts inside cabinets or on conveyor belts. Proper water pressure is crucial for effective contaminant removal. Cabinets are built to withstand high-pressure operations and resist corrosive materials.

Low Water Shut-Off Valve

Maintaining proper water levels is critical to prevent heater damage. An automatic shut-off valve stops operation when water levels are too low, resuming only when levels are restored.

How Parts Washers Work

Parts washer operation involves timed cycles. Parts are placed on a turntable, the door is closed, and the cleaning cycle begins. High-temperature, high-pressure water-detergent solutions remove dirt and contaminants.

A closed-loop waste minimization system is integral to operation. Key operational factors include:

Power and Pressure

Cleaning effectiveness depends on power level—higher power provides stronger cleaning action. This comes from solution pressure and flow rate, which combine to remove soils and residues.

Solution Temperature

Higher temperatures reduce oil and grease viscosity, making them easier to remove. Heating solutions to about 160°F (71°C) improves grease breakdown.

Temperature increases of approximately 54°F (12.22°C) can double chemical reaction rates, yielding faster, more thorough cleaning.

Chemical Solution Composition

Chemical additives enhance cleaning power. Some solutions have abrasive or corrosive properties for tougher stain removal. Alkaline chemicals are commonly used to reduce environmental impact.

Chapter 2: Types of Aqueous Part Washers

Aqueous part washers are essential industrial cleaning devices available in various types, each designed for specific cleaning needs in manufacturing, automotive, aerospace, and metalworking applications. They use water-based solutions, eco-friendly detergents, and advanced mechanical systems to remove oil, grease, carbon deposits, and other contaminants.

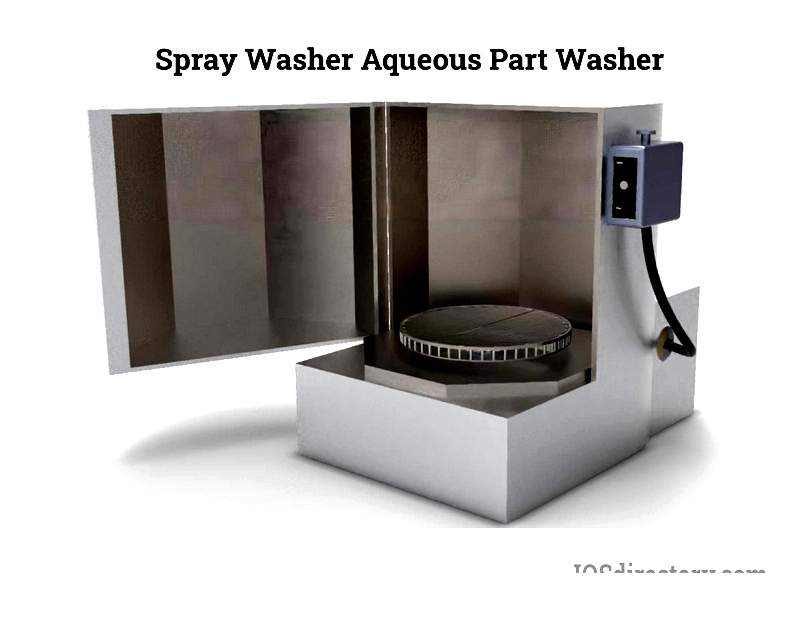

Spray Washer Systems

Automated spray washers use high-impact cleaning via spray jets. These cabinets employ heated aqueous solutions at moderate to high pressures to clean various surfaces. Available in multiple capacities, they handle small parts to large engine blocks. Strategically placed nozzles ensure complete coverage, reducing cycle times and labor in industries like automotive and aerospace.

Parts are loaded into perforated baskets and rotated under powerful sprays. This method cleans complex geometries and removes stubborn residues. Spray washers offer energy-efficient, eco-friendly solutions for high-throughput precision cleaning.

Sink-Top Washers

Designed for manual cleaning of individual or small batches, sink-top washers feature a sink mounted on a sealed drum. A recirculating pump and brushes allow precise cleaning of delicate components. Ideal for maintenance and small operations requiring spot cleaning.

Ultrasonic Washers

These systems use cavitation technology for high-precision cleaning of intricate components. Ultrasonic waves create microscopic bubbles that remove contaminants from hard-to-reach areas. Suitable for medical instruments, electronics, and aerospace hardware.

Available as benchtop units or large-scale systems, ultrasonic washers deliver thorough cleaning for automated and precision applications.

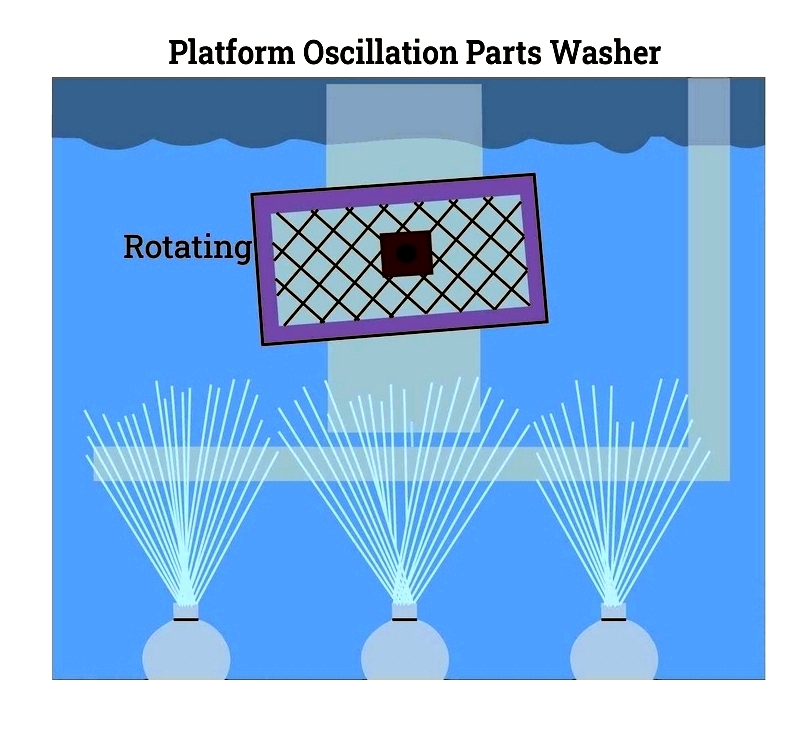

Immersion Washers

These robust systems clean by submerging parts in water-based solutions. Agitation mechanisms enhance cleaning of complex geometries like gears and valves. Some models combine immersion with sprays or ultrasonics for multi-stage cleaning.

Conveyor Washers

Continuous cleaning systems ideal for mass production. En