Introduction

This article provides a comprehensive overview of overmolding.

Readers will gain understanding of:

- The definition and process of overmolding

- Overmolding guidelines

- Key considerations in overmolding

- Types and processes of overmolding

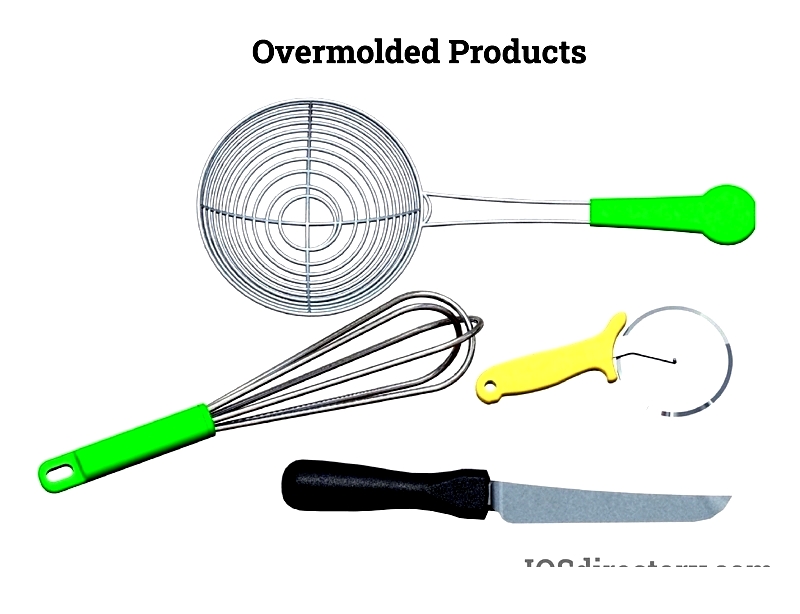

- Applications of overmolding

- Benefits of overmolding

- And more...

Chapter One: Understanding Overmolding and Its Process

What is Overmolding?

Rubber and plastic materials are essential components in numerous everyday products, valued for their strength, flexibility, and ability to be shaped for industrial applications. Certain formulations withstand extreme conditions, making them ideal for demanding uses. Overmolding further enhances these materials' functionality by creating layered products that offer improved durability, aesthetics, and additional features.

This technique applies to various manufacturing sectors, using injection molding to combine multiple materials into a single unit. The process allows two or more material layers to bond together. Both rubber and plastic can serve as the base material (substrate), which may be partially or fully covered by overmolded materials.

Originally developed to improve product appearance, injection overmolding now enhances performance by increasing chemical resistance, providing electrical insulation, improving grip, and more.

Two primary overmolding processes exist:

- Soft Material Over Hard Material: Thermoplastic elastomers (TPE) like TPE-V, TPE-U, TPE-E, and TPE-A are molded onto substrates such as ABS. These "soft cladding" solutions offer improved insulation, chemical resistance, ergonomics, grip, aesthetics, and functionality.

- Hard Material Over Hard Material: This secondary process often involves molding hard plastic over metal inserts or combining transparent and opaque rigid plastics.

Overmolding benefits industries requiring rapid prototyping, particularly for custom parts combining rubber/plastic with metals. It enhances product grip while maintaining durability - improving power tool handles or surgical instruments, where TPU often outperforms ABS. The technique also serves aesthetic purposes, like team-colored mouthguards or branded tractor components.

This innovative tooling method reduces production costs, shortens cycle times, and expands design possibilities. Its adoption spans mobile phones, pens, automotive, appliances, tools, and consumer goods.

How is Overmolding Performed?

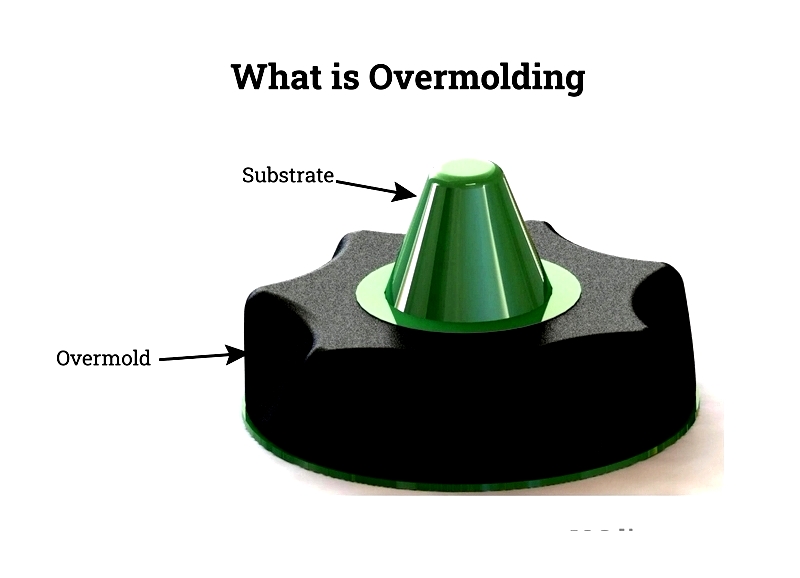

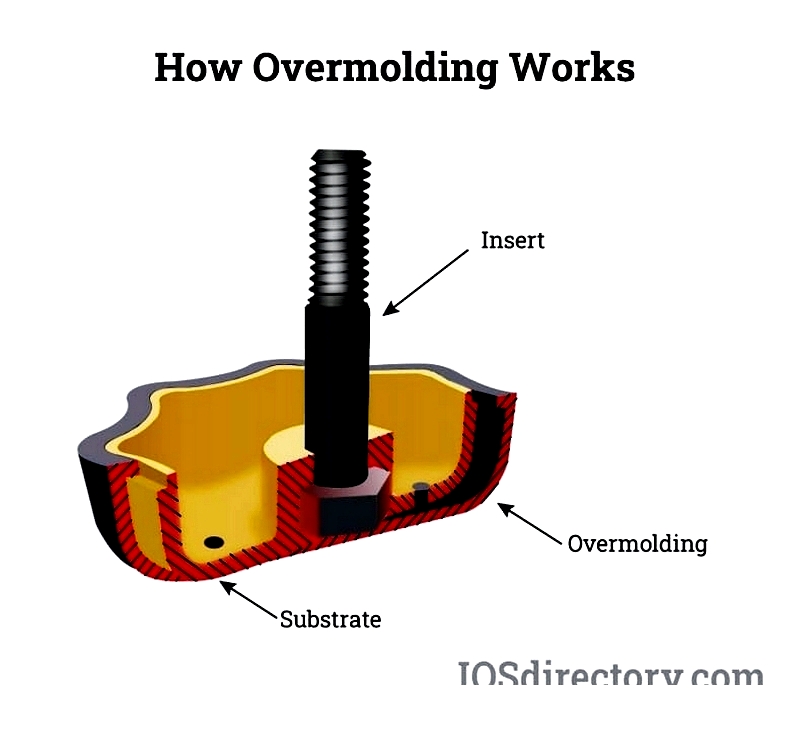

The process combines two or more materials (identical or different) to create components. Understanding overmolding requires knowledge of its two stages: substrate preparation and the overmolding process itself.

The substrate forms the base material, while the overmold material is applied atop it. Some designs may incorporate multiple overmold layers, depending on product requirements and manufacturing innovation.

Guidelines for Overmolding

This technique enhances physical properties and aesthetics while following injection molding principles with additional considerations:

- Maintain proper draft angles, uniform wall thickness, and clean transitions

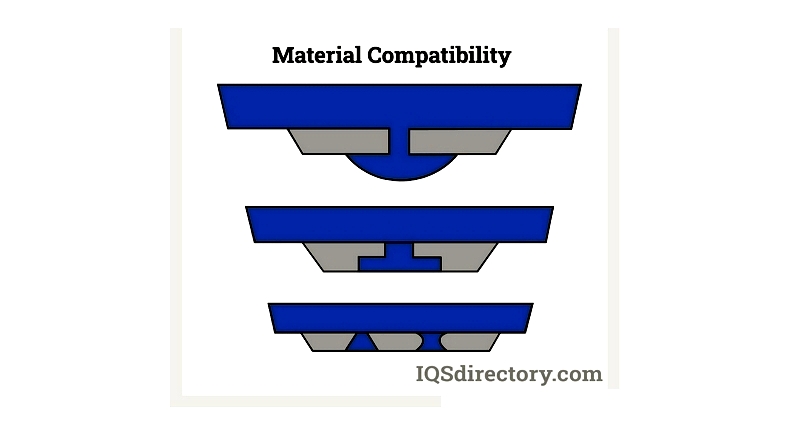

- Overmold material should have lower melting temperature than substrate and not exceed its thickness

- Use mechanical interlocks when chemical bonding isn't feasible

- Substrate texture aids adhesion; overmolded surfaces should align with or slightly recess below substrate

Chapter Two: Key Considerations in Overmolding

Manufacturers must evaluate several factors to ensure quality and performance in overmolded products. This specialized injection molding technique serves automotive, medical, electronics, and industrial sectors. Customers should assess these factors when selecting overmolded components to optimize production efficiency, durability, and satisfaction. Key considerations include:

Bonding

Effective substrate-overmold adhesion is crucial. In ideal cases, the overlay breaks before separating from the substrate. While chemical bonds are preferred, they're not always necessary. For example, electronic housing gaskets only require sufficient bonding to prevent misalignment during assembly, eliminating the need for manual gasket installation.

The primary goal is material fusion through two-shot molding, insert molding, or multi-material processes. When materials don't bond naturally, mechanical retention features like indentations or textured surfaces enhance connection.

Engineers often combine mechanical interlocks (undercuts, grooves) with chemical bonding for optimal results, especially in waterproof, high-impact, or vibration-resistant applications.

Bonding Techniques:

- Physical: Uses buckle designs or surface treatments with mechanical joints

- Chemical: Leverages molecular interactions for stronger bonds

Temperature

Material selection must account for processing and operational temperatures. Medical devices, automotive components, and electronics require materials with stable heat deflection temperatures (HDT), low thermal expansion, and high temperature resistance.

Friction

Surface friction affects both grip and bond durability. Rougher textures improve mechanical bonding, while TPEs, silicones, and TPVs enhance grip in tools, automotive interiors, and consumer goods.

Thickness

Material thickness impacts vibration damping, sound insulation, and impact protection. While thicker layers improve performance, excessive thickness affects molding precision and cycle times.

Materials

Key materials include thermoplastics (PP, PC, ABS), engineering plastics (nylon), TPEs/TPUs, LSR, and metals for insert molding. Selection depends on chemical resistance, UV stability, biocompatibility, flexibility, and cost.

Hardness

Shore hardness (A/D scales) balances durability with tactile feel. Applications requiring impact protection or soft grips must optimize hardness for both performance and user experience.

Additional Considerations

Other important factors include:

- Surface Preparation: Cleaning and texturing improve bonding

- Mold Design: Proper vents and gates ensure material flow

- Regulatory Compliance: Meeting FDA, RoHS, UL standards

- Cost Optimization: Minimizing tooling costs and waste

Understanding these considerations helps manufacturers select optimal materials and processes, resulting in reliable, cost-effective overmolded products.