Introduction:

You'll find the most comprehensive information about perforated metals here.

This guide covers:

- What perforated sheet metal is

- The manufacturing process of perforated sheet metals

- Materials used in perforated sheet metal production

- Products made from perforated metals

- And much more...

Chapter One – What is Perforated Sheet metal?

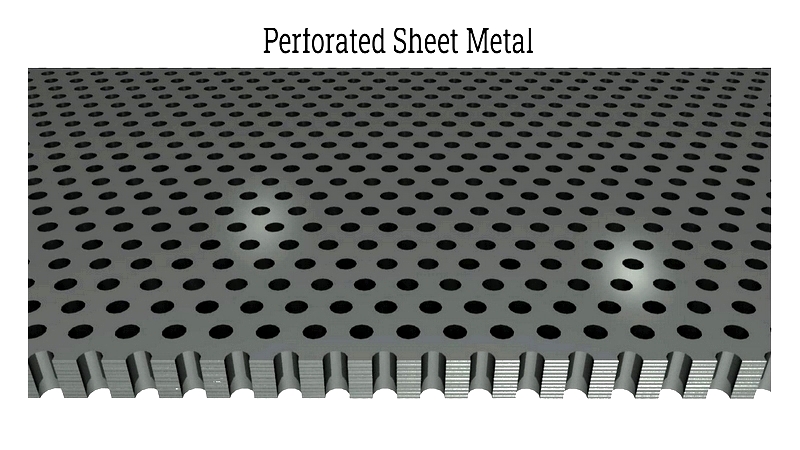

Perforated metal consists of sheet material stamped, punched, or crafted to create holes, slots, or decorative shapes. Manufacturers use various metals including steel, aluminum, stainless steel, copper, and titanium. Beyond enhancing appearance, perforation provides functional benefits like improved protection and noise reduction.

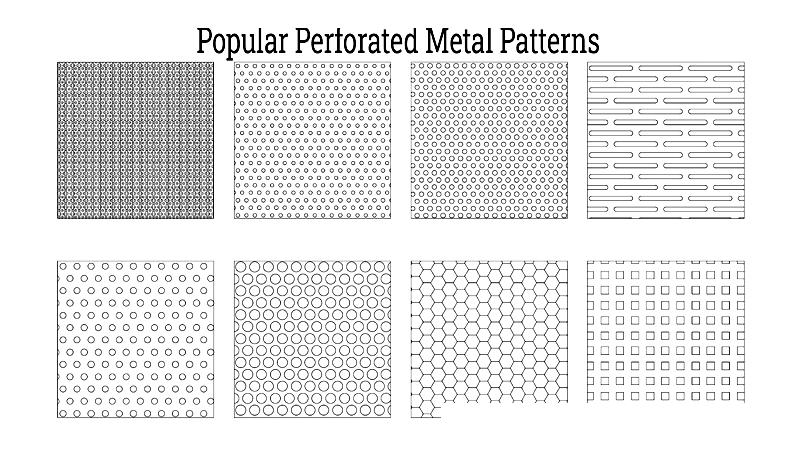

Selection depends on factors like size, gauge thickness, material type, and intended use. The range of possible shapes is extensive, including round holes, square cutouts, slotted patterns, hexagonal designs, and more.

Chapter Two – How Perforated Sheet metals are Made

Modern manufacturing has transformed perforation from labor-intensive to automated processes. The three primary techniques—punch press, rotary pin, and laser cutting—form the basis of contemporary production. These methods enable high-volume, precise manufacturing for industries including architecture, filtration, acoustics, HVAC, and automotive.

Each technique offers unique advantages for creating different configurations, shapes, and patterns to meet specific requirements.

How Perforated metals are Made

Sheet metal

Production begins with thin, flat sheets of materials like stainless steel, aluminum, or copper. These sheets can be cut, bent, or shaped as needed. Thickness is measured in gauges, with higher numbers indicating thinner materials. Material choice affects durability, corrosion resistance, and suitability for various environments.

Choosing a Pattern

Pattern selection depends on application requirements, with options ranging from standard to custom designs. Common patterns include round, square, slotted, and hexagonal holes, each offering distinct characteristics. The balance between hole size and spacing is crucial for strength and functionality.

Modern CAD software and CNC machinery enable precise, repeatable custom patterns. Generally, metal thickness shouldn't exceed hole size to maintain manufacturing efficiency.

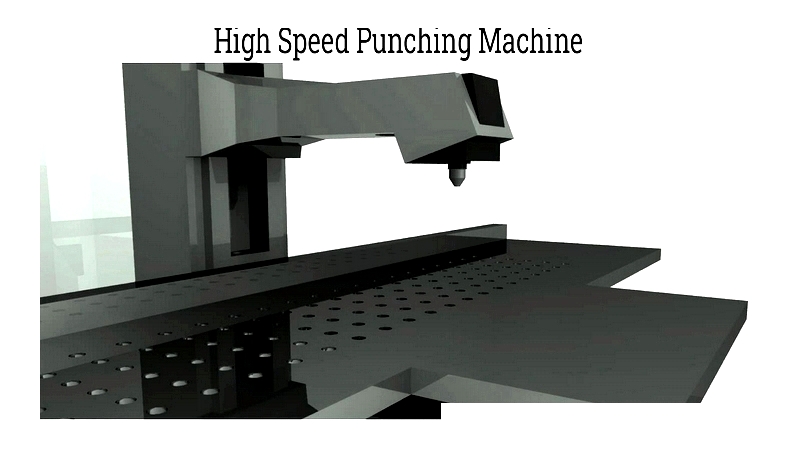

All-Across Perforating Press

This high-speed method achieves up to 1600 punches per stroke, making it ideal for large-scale production. It handles materials up to 60 inches wide and 0.25 inches thick, performing up to 600 strokes per minute.

XY Axis Punch Press

This programmable method creates intricate patterns by moving across the sheet metal. It's particularly useful for custom architectural panels and specialty components requiring unique configurations.

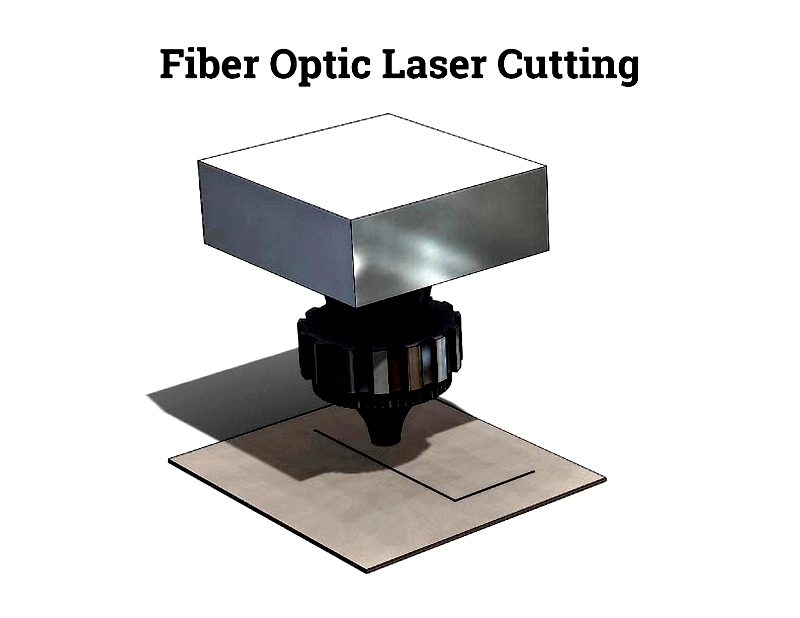

Laser Perforation

The most precise technique, laser perforation creates detailed patterns with reinforced edges. CO2 and fiber lasers offer different advantages in precision and efficiency, making them ideal for complex designs and prototyping.

Plasma Perforation

Using high-temperature plasma, this method efficiently cuts through conductive metals of any thickness. It's best for heavy-duty applications where speed outweighs precision requirements.

Water Jet Cutting

This cold-cutting technique uses high-pressure water (with or without abrasives) for precise patterns without heat distortion. It's ideal for intricate designs in architectural and decorative applications.

Nibbling Machine

This versatile method progressively cuts metal sheets, creating custom shapes and patterns. It's particularly effective for enclosures, control panels, and machine parts.

Value Added Processes

Post-perforation processing may include welding, bending, powder coating, or other finishing techniques to enhance functionality and appearance.

Welding

Perforated metals are often welded into tubular shapes for filters, exhaust systems, and structural components. Various welding methods ensure durable, seamless results.

Bending

Sheets can be bent to various angles using CNC-controlled press brakes. This process ensures consistent quality for both functional and decorative applications.

Considerations When Purchasing

Key factors include material type, gauge, pattern, open area percentage, and finishing needs. Consult manufacturers to ensure the product meets your specific performance requirements.

Summary

Understanding perforation techniques helps select the right solution for your application. Consult with suppliers to bring your design vision to life.

Chapter Three – Top Sheet metal Perforating Machines

Modern manufacturing utilizes advanced machinery for precise, efficient perforated metal production. These machines create products for filtration systems, architectural facades, and more.

Trumpf TruPunch 5000

Manufacturer: Trumpf

Key Attributes:

- High-speed hydraulic punching machine

- Handles complex punching and forming operations

- Integrated automation for efficiency

- Tool rotation for varied patterns

Amada EMK 3610NT

Manufacturer: Amada

Key Attributes:

- Energy-efficient electric servo-driven press

- Automated processing capabilities

- User-friendly interface

- Supports prototyping and production

Finn-Power C5 Compact Express

Manufacturer: Prima Power

Key Attributes:

- Compact servo-electric punch press

- Ideal for small to medium production

- Energy-efficient operation

- Precision alignment capabilities

Durma TP6A

Manufacturer: Durma

Key Attributes:

- Heavy-duty CNC hydraulic press

- Handles thick-gauge materials

- Automatic tool changing

- Intuitive programming interface