Introduction

This article provides information about spur gears, including their applications and advantages.

You will explore topics such as:

- What is a Spur Gear?

- Types of Spur Gears

- Applications of Spur Gears

- Manufacturing Process of Spur Gears

- Advantages of Spur Gears

- And More...

Chapter One – What is a Spur Gear?

A spur gear is a cylindrical gear with teeth parallel to its axis, used to transmit mechanical motion while controlling speed, power, and torque between shafts. As the most common type of cylindrical gear, spur gears feature a simple design with straight teeth evenly spaced around the gear's circumference. While spur gear designs may vary in hub shape and thickness, these variations do not affect the gear's face.

Spur gears are widely used in mechanical systems due to their efficiency in adjusting speed and torque by transferring power between shafts. Their design is ideal for applications requiring quick and efficient changes in motion, speed, and torque. Typically, spur gears are arranged in series to achieve these adjustments effectively.

Chapter Two – What are the different types of spur gears?

Spur gears are among the most commonly used components in power transmission systems. Their effectiveness in transferring rotary motion and torque depends on gear design, construction, and material quality. Manufacturing spur gears requires high-quality materials such as alloy steel, stainless steel, brass, bronze, and engineering plastics to ensure durability, load capacity, and low wear rates. Precise dimensional specifications during fabrication are essential for optimal performance, minimizing vibration, and maximizing energy efficiency in gear trains and motion control applications.

Spur gears come in various sizes, from miniature precision gears used in instrumentation and robotics to large industrial gears in conveyors, motors, and heavy machinery. Despite size differences, all spur gears share key characteristics and functional elements, including:

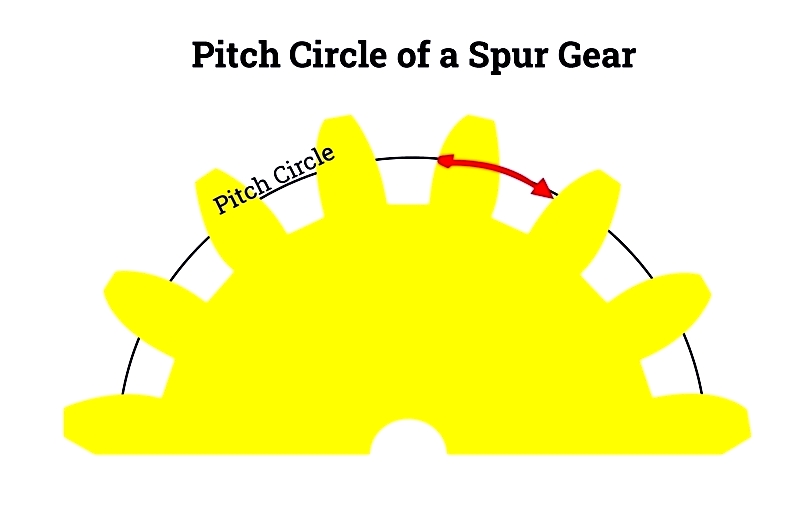

Pitch Circle

The pitch circle is an imaginary reference circle that defines tooth positioning on a spur gear. It serves as a critical geometric baseline for gear design, representing the distance between tooth faces. The area above the pitch circle is the addendum (tooth height), while below is the dedendum (tooth depth). In properly meshed gears, the pitch circles of mating gears are tangent, ensuring precise power transmission and minimizing backlash.

Diametral Pitch

Diametral pitch (DP) measures the number of teeth per inch of the gear's pitch diameter. It helps determine gear compatibility for smooth meshing. Selecting the correct diametral pitch is crucial for achieving desired gear ratios, increasing power density, and reducing noise in high-speed applications.

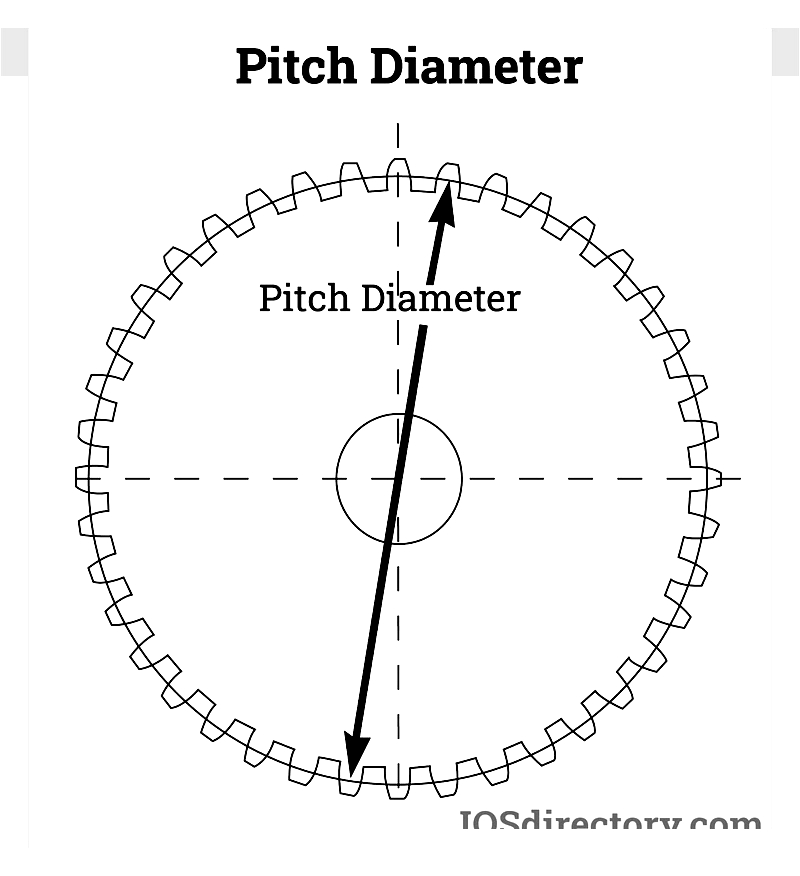

Pitch Diameter

Pitch diameter is the diameter of the pitch circle, a fundamental parameter for calculating center distance and gear module. It determines gear size, load distribution, and is essential when selecting compatible spur gears for gearboxes or coupling drives.

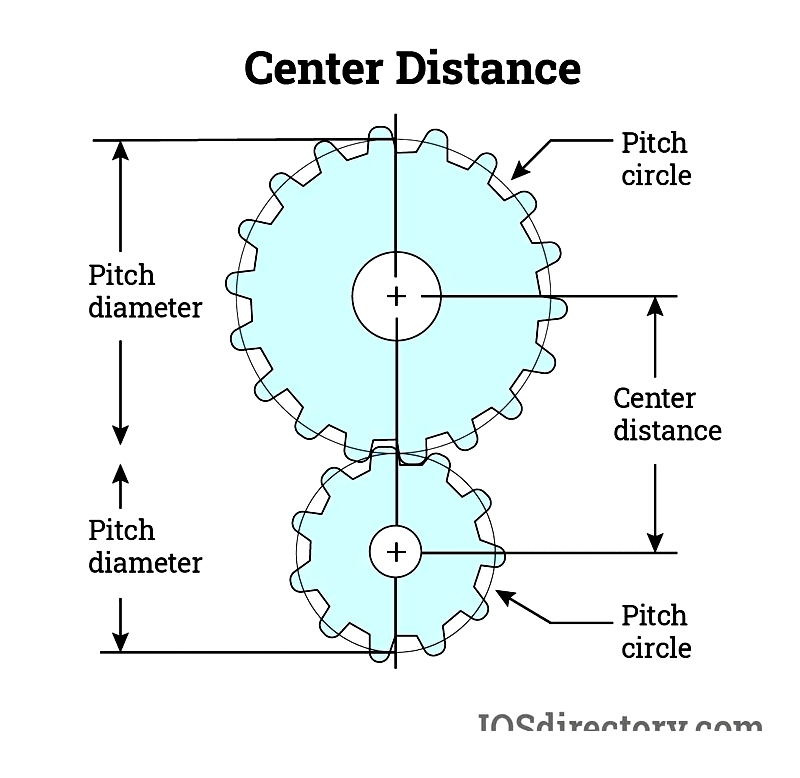

Center Distance

Center distance is the linear measurement between the rotational axes of two meshing gears. It is calculated by summing the pitch radii of both gears. Proper center distance calculation ensures efficient gear engagement, prevents tooth interference, and extends gear life in gear trains and motion systems.

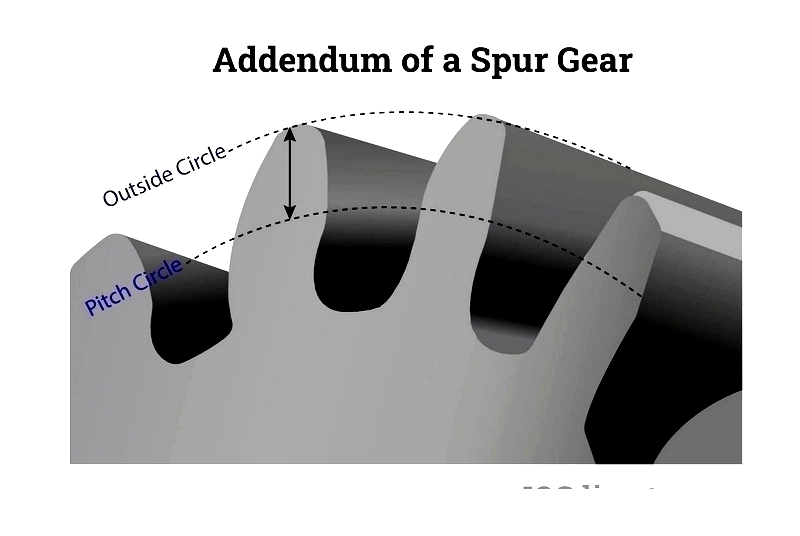

Spur Gear Addendum

The addendum is the radial distance from the pitch circle to the crest of a gear tooth. Proper addendum sizing affects tooth strength and prevents undercutting or premature wear during power transmission.

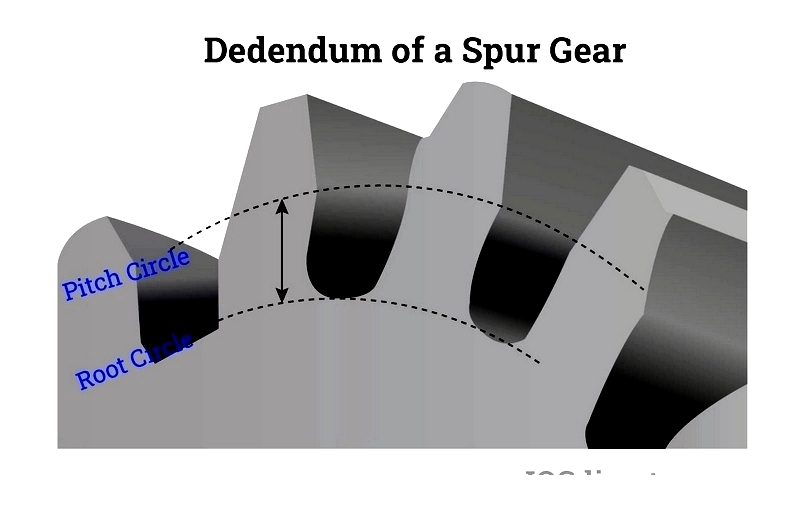

Gear Dedendum

The dedendum measures the radial depth of a tooth below the pitch circle. It exceeds the addendum to provide clearance for engaging gears, reducing jamming risks and ensuring effective lubrication and load capacity.

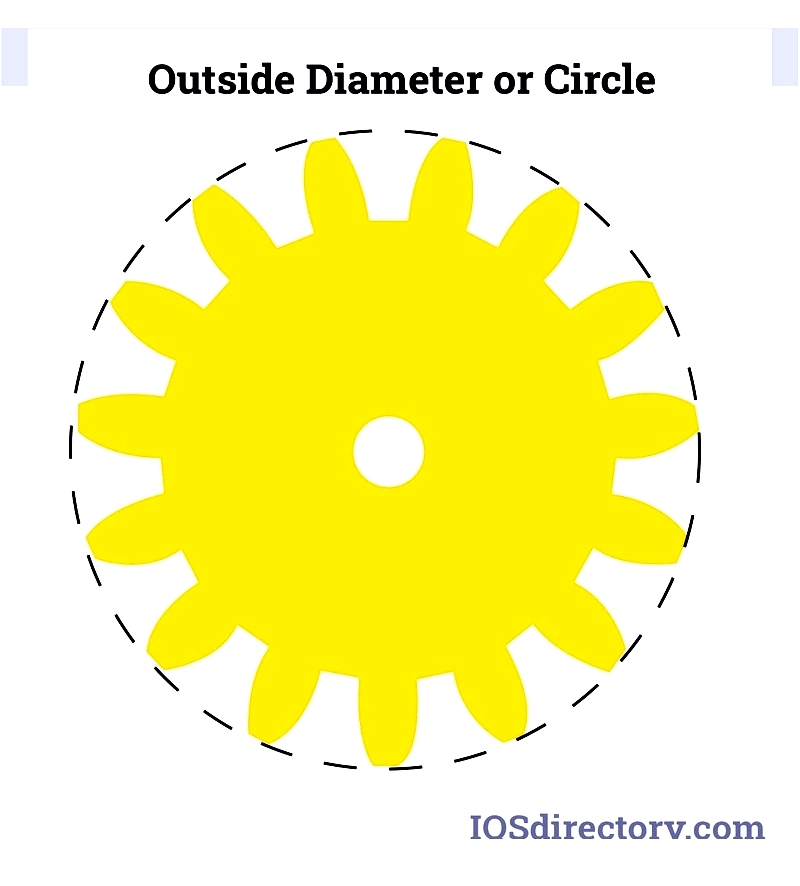

Outside Diameter (OD)

The outside diameter (OD) is the total diameter of a spur gear measured from the outermost tips of the teeth. This measurement ensures proper gear alignment in assemblies and helps calculate maximum tooth size and housing design.

Root Diameter

The root diameter is the diameter of the circle at the bottom of the gear teeth. It is critical for determining gear strength and fatigue resistance and helps evaluate minimum shaft size for gear mounting.

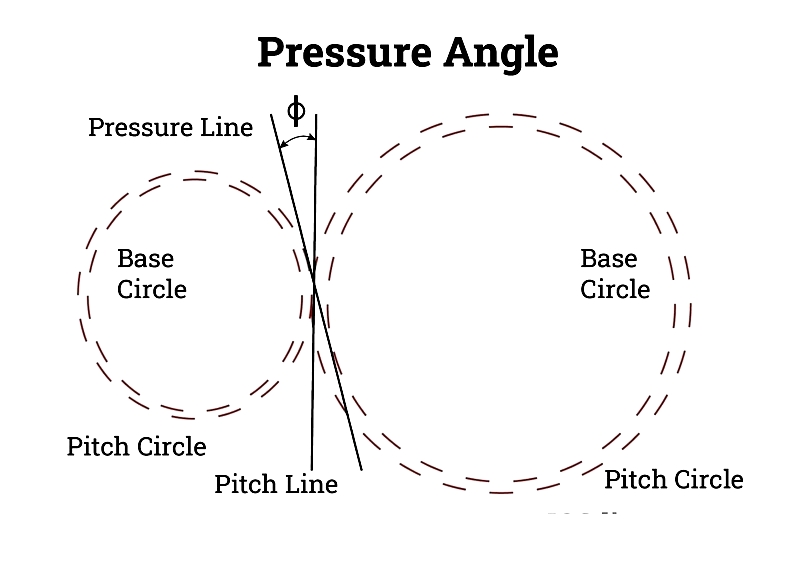

Pressure Angle

The pressure angle is a key design parameter in involute spur gears, defined as the angle between the line of action and a tangent to the pitch point. Common pressure angles are 20° and 14.5°, affecting tooth profile, noise generation, and load transfer efficiency. Higher pressure angles result in stronger teeth but may increase friction and noise.

Whole Depth

The whole depth is the total radial measurement from the tip to the root of a gear tooth, calculated as the sum of the addendum and dedendum. This dimension determines engagement depth between meshing teeth, impacting gear strength and compatibility in multi-stage gear trains.

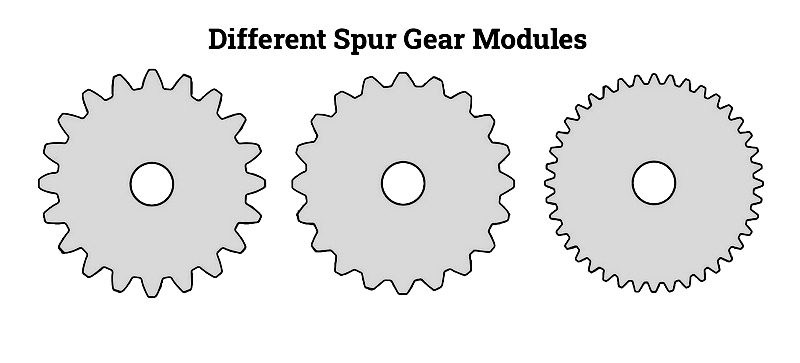

Module

The module is the metric equivalent of diametral pitch, expressing gear tooth size in millimeters. It ensures seamless meshing of gears with the same module. Choosing the proper module is critical for quiet operation, efficient torque transfer, and minimal wear. The module is calculated by dividing the pitch diameter by the number of teeth. Larger modules indicate larger, heavier-duty teeth for industrial applications.

Below, the left gear shows a standard involute profile, the center a higher pressure angle, and the right a larger module—demonstrating how tooth shape, module, and pressure angle affect performance.

Spur Gear Types

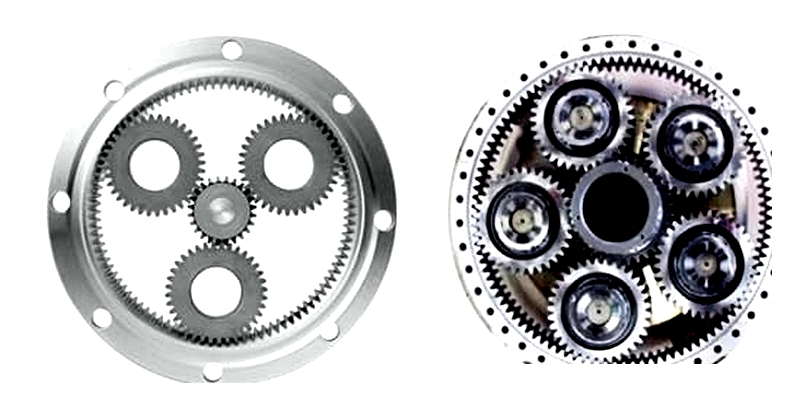

Planetary Spur Gear Drive

Planetary spur gear drives consist of a sun gear, planet gears, and a ring gear. The sun gear rotates centrally, while planet gears orbit inside the ring gear. This compact arrangement offers high power density and torque transmission in a small footprint. By fixing or driving different gears, speed reduction, torque multiplication, and directional changes can be achieved.

Planetary gearboxes are used in robotics, industrial automation, electric vehicles, wind turbines, and precision servos due to their efficiency, durability, and smooth operation.

(from STD Precision Gear and Instrument Inc.)

(from STD Precision Gear and Instrument Inc.)