Introduction

This article covers everything you need to know about automatic screwdrivers and their applications.

You will learn about:

- What an Automatic Screwdriver is

- How Automatic Screwdrivers Work

- Types of Automatic Screwdrivers

- Applications of Automatic Screwdrivers

- And much more...

Chapter 1: What is an Automated Screwdriver?

An automated screwdriver is a specialized tool designed to automatically insert screws during manufacturing and assembly processes. Available in various sizes, designs, and configurations to meet different production needs, these devices share a common purpose: efficient screw insertion. They enhance speed, accuracy, quality, and efficiency in modern production environments.

The automated screwdriver mechanism involves feeding screws into the device, which then securely fastens them to assemblies. This process relies on three main components working in harmony: the screw driving unit, controller, and screw feeder.

Automated screwdrivers offer particular advantages in specific situations. When multiple workers are needed for screw driving tasks, these tools significantly reduce labor costs. They also prove cost-effective for processes consistently using the same screw type, substantially improving production efficiency.

Chapter 2: Types of Automatic Screwdrivers

Automatic screwdrivers enhance productivity, control process rates, and provide operational flexibility in manufacturing. They deliver consistent, accurate screw fastening with high reliability in modern assembly lines, outperforming manual solutions in speed and efficiency while requiring minimal maintenance. Their ability to autonomously drive thousands of screws with programmed torque settings makes them indispensable in electronics, automotive, medical device, and appliance manufacturing.

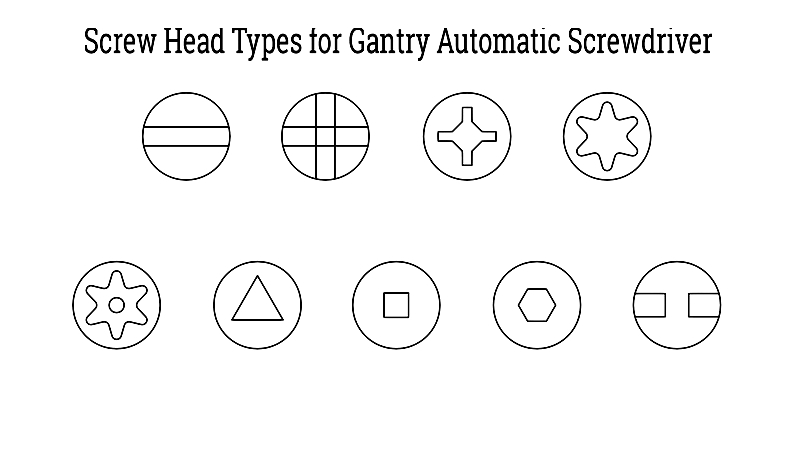

When selecting automatic screwdrivers for industrial automation, consider both the screwdriver mechanism and its delivery system. Available in electric, pneumatic, torque-controlled, and programmable variants, each type offers specific features for different automated systems. The choice depends on product size, production speed, automation level, precision requirements, and fastener size.

The five systems described below represent just some of the available options. Manufacturers continually develop custom solutions for evolving assembly needs. Additional differentiating factors include the number of screwdrivers in a system (single or multi-spindle) and programmability levels (including smart, IoT-enabled, or vision-assisted controls).

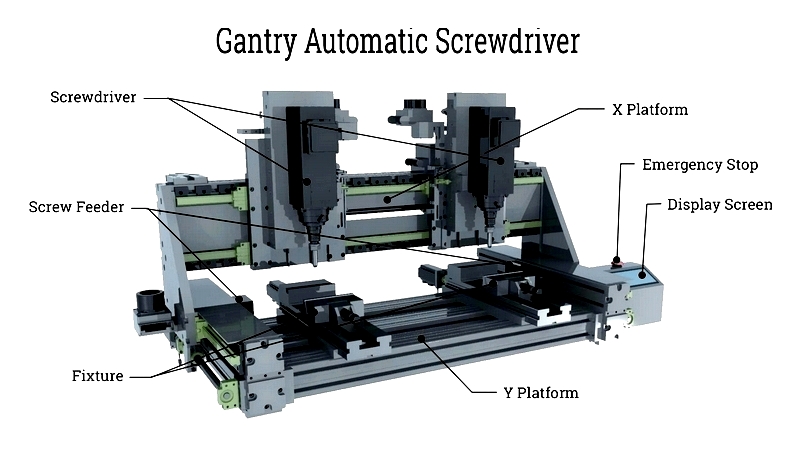

Gantry Automatic Screwdriver

Gantry-style screwdrivers operate along X and Y axes using servo motors and sliding tables for precise positioning. Their robust rail systems enable accurate screw fastening at programmed locations. Highly programmable and compatible with automatic feeders, they can accommodate multiple screwdriving heads for complex assemblies in high-mix production.

While automating the fastening process, gantry screwdrivers typically require manual loading/unloading. Unlike fixed assembly line models, they offer portability and repositioning flexibility. Their versatility supports various screw types, lengths, and diameters, making them valuable for electronics, automotive, and industrial applications.

Key features include torque monitoring and automated control for precise fastening. Integrated sensors and digital controllers ensure consistent torque and depth, reducing quality issues in tolerance-sensitive industries.

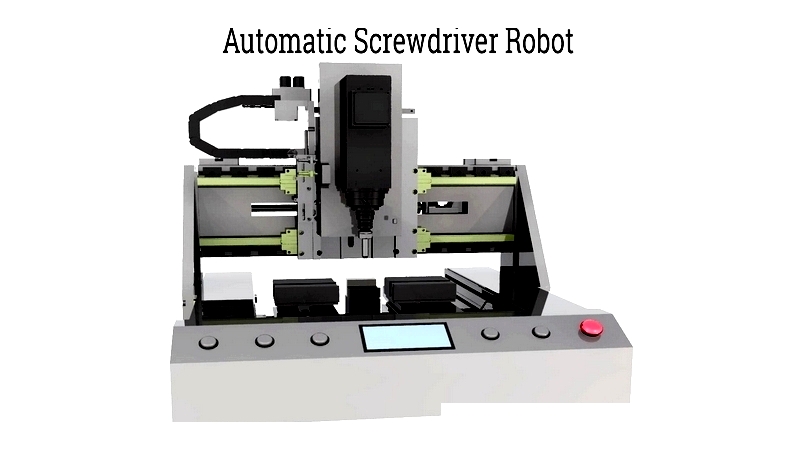

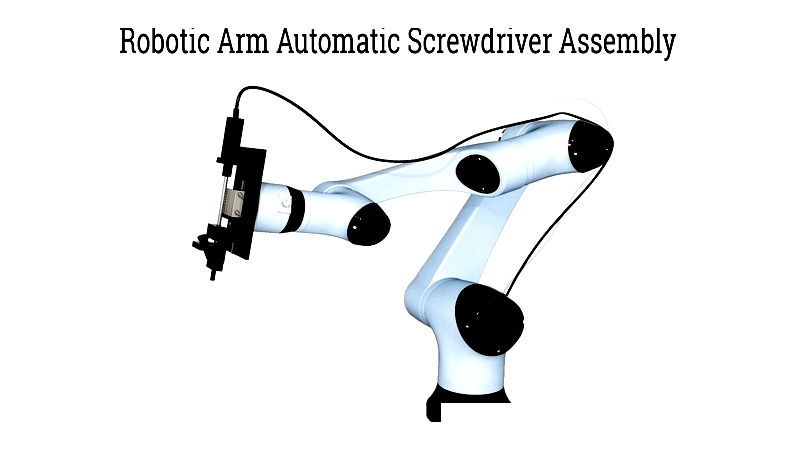

Automatic Screwdriver Robot

Robotic screwdrivers handle repetitive fastening tasks with precision, optimizing efficiency and reducing labor costs. These systems typically combine a robotic arm, programmable screwdriver attachment, vision system, motion controller, and user interface.

The robotic arm's flexible joints enable precise screw placement in various configurations, ideal for electronics, automotive, and consumer goods assembly. Vision systems provide real-time monitoring for accurate, defect-free fastener placement.

User interfaces allow programming of torque, screw length, batch size, drive patterns, and production cycles. Often integrated with MES/ERP systems, they support Industry 4.0 connectivity needs.

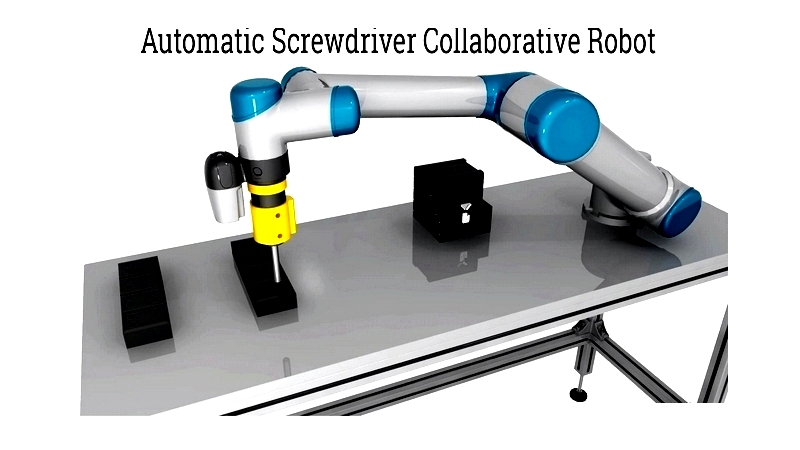

Collaborative Automatic Screwdrivers (Cobots)

Collaborative robots combine human operators with automation technology. Designed for safe human interaction, these compact, flexible systems address workforce shortages and reduce repetitive task fatigue while improving ergonomics and quality.

Unlike industrial robots, cobots feature built-in safety sensors, require less space, and offer tool-less setup. Recent advancements in effector technology have expanded their applications across electronics and medical device manufacturing.

In these systems, humans handle exceptions and quality checks while robots perform repetitive screwing tasks, optimizing efficiency and minimizing errors.

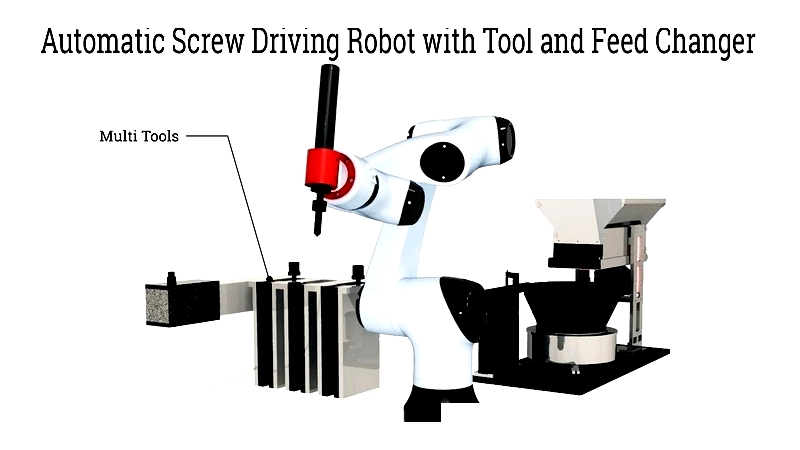

Automatic Tool Changer Screwdriver

These advanced systems accommodate multiple screw types without manual retooling, using modular feed mechanisms and quick-change heads. They switch seamlessly between screwdriver heads and feeding modules for different product variants.

Features include encoded tool selection and flexible feeding units for quick changeovers. Integrated safety systems halt operations during manual intervention, crucial for quality-focused industries.

Multiple Spindle Automatic Screwdriver

Multi-spindle systems insert multiple screws simultaneously, dramatically increasing throughput. Each programmable spindle accommodates different screw sizes and types, synchronized with high-speed feeding mechanisms.

This space-saving design reduces cycle times in mass production. Often integrated with digital monitoring, these systems provide traceability and support statistical process control.

When selecting systems, consider screw compatibility, torque accuracy, speed, feeding mechanisms, safety standards, and programmability to align with automation goals.

Chapter 3: How Automatic Screwdriver Systems Work

These industrial automation tools streamline screw insertion in manufacturing, enhancing productivity and precision. Key components include the screw feeder, screwdriver unit, spindle, controller, and effector, working together under intelligent control for high-speed, accurate fastening.

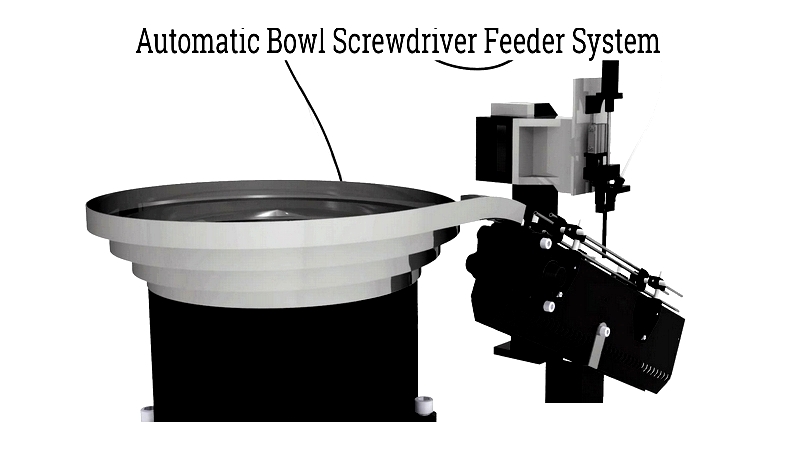

Feeder

Feeders provide high-speed screw delivery using hoppers, selection mechanisms, and vibratory bowls. Various configurations handle different screw sizes and types, with advanced features reducing jams and increasing uptime.

Screwdriver Unit

Available in handheld, fixed, and movable configurations, these units incorporate high-torque motors and advanced controls. Robotic solutions enable flexible automation with vision-guided precision for complex assemblies.

Spindle

The spindle rotates and secures fasteners with precise force. Modern designs use various drive systems with integrated