Introduction

This article provides an in-depth exploration of homogenizers.

Continue reading to discover key topics including:

- What is a homogenizer?

- Underlying theories and principles

- Different types of homogenizers

- Additional functions of homogenizers

- And more…

Chapter 1: What is a Homogenizer?

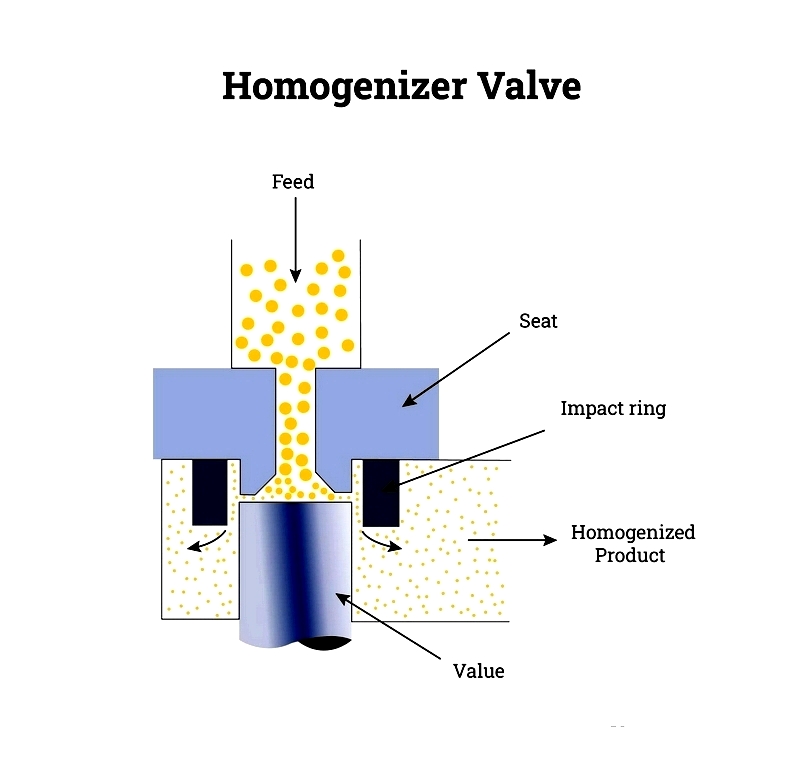

A homogenizer is a specialized mixing device that creates uniform blends by forcing materials through a narrow passage. It applies forces like turbulence, cavitation, and high pressure to evenly distribute solution components. Equipped with a positive displacement pump and homogenizing valve, the device pushes material under pressure through a small gap between the valve seat and valve. This pressurized flow and resulting turbulence ensure thorough mixing. Beyond simple blending, homogenizers perform emulsification, suspension, grinding, dispersion, and dissolution. Industries such as pharmaceuticals, beverages, and chemicals rely on homogenizers to improve product quality and consistency.

Homogenizers often work with high shear mixers, batch mixers, and paddle mixers, typically installed downstream to achieve finer mixtures. However, some models struggle with highly coarse materials, which can increase energy consumption, reduce flow rates, generate heat, and accelerate wear. Upstream mixers help prepare materials through premixing before homogenization.

History

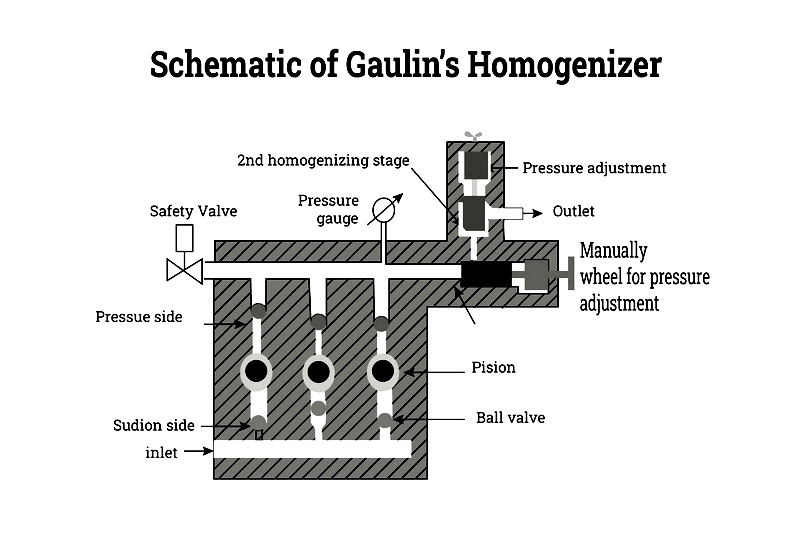

The development of homogenizers began in the early 20th century with Auguste Gaulin's pioneering milk homogenization design. His apparatus featured a three-piston positive displacement pump and capillary tubes that converted fluid pressure into velocity. Milk droplets were then forced against a downstream concave valve.

Later improvements replaced multiple capillary tubes with a single narrow tube, where the primary homogenization occurred. This innovation led to various gap geometries, expanding the equipment's applications and effectiveness.

Chapter 2: What are the Theories and Principles Behind Homogenizers?

Several theories explain the science of homogenization, particularly in high-pressure systems. This critical engineering process serves industries like food and beverage, pharmaceuticals, cosmetics, biotechnology, and chemical processing by achieving consistent particle or droplet size distribution. The two primary theories are globule disruption by turbulence and cavitation, which describe how mechanical forces create stable emulsions and suspensions.

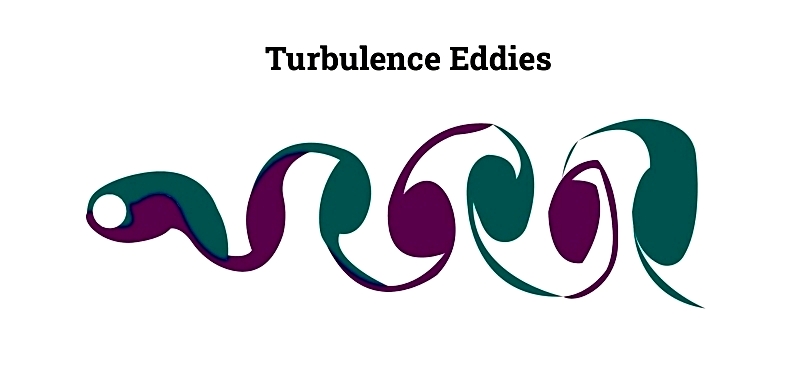

The globule disruption by turbulence theory proposes that liquid jets exiting a narrow gap generate intense turbulence with numerous small eddies. Higher pressure increases jet velocity, enlarging and energizing these eddies. Colliding droplets deform and break into smaller, more uniform particles. The degree of size reduction typically correlates with applied pressure, making pressure optimization crucial for product uniformity.

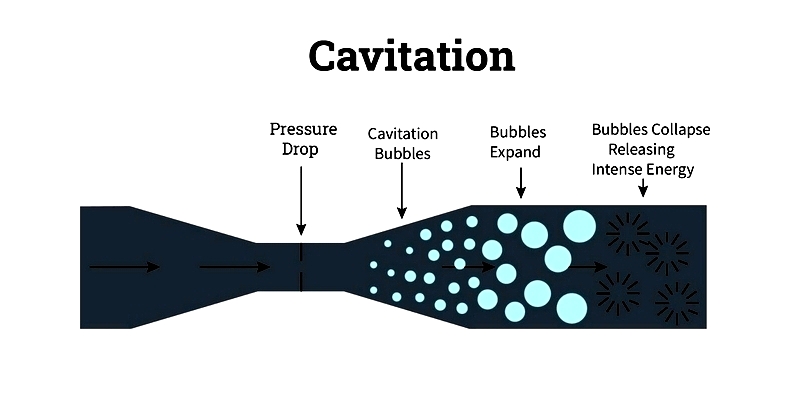

The cavitation theory explains how pressure changes create vapor bubbles in liquid. When these bubbles collapse, they release energy that breaks apart suspended droplets or particles, resulting in finer mixtures. The combination of turbulence and cavitation is essential for effective mechanical disruption in both high-pressure and ultrasonic homogenizers.

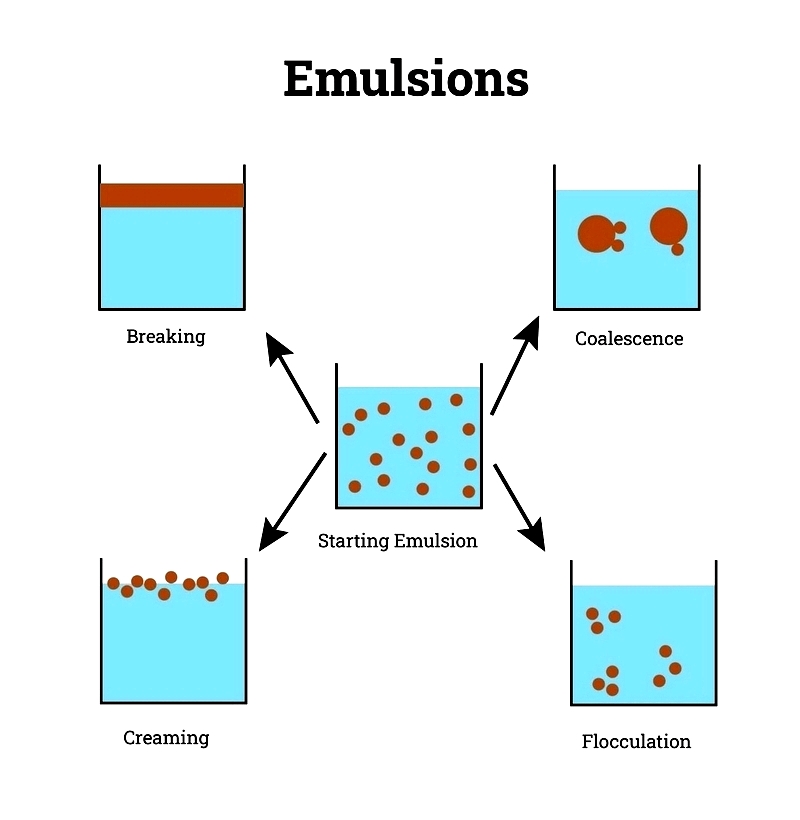

Homogenizers commonly process emulsions and suspensions. An emulsion combines immiscible liquids like oil and water, which homogenization transforms into stable colloidal solutions with improved texture and shelf-life. Examples include milk, mayonnaise, paints, and pharmaceutical creams.

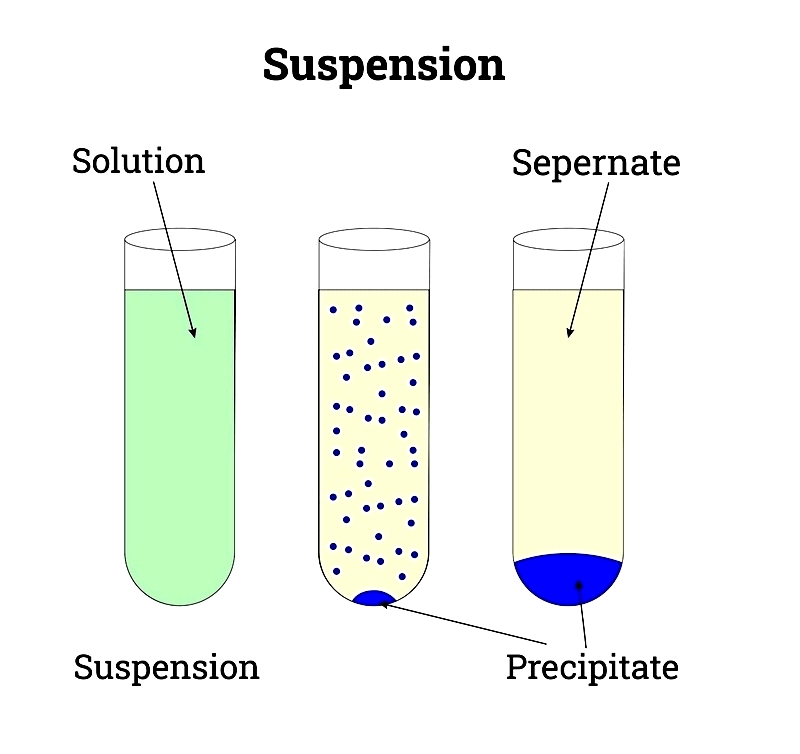

A suspension contains solid particles that don't dissolve and may settle over time. Homogenizers reduce particle size to prevent sedimentation and improve uniformity in products like pharmaceutical suspensions, pigment dispersions, and wastewater treatments.

Particle sizes in suspensions vary widely, with some visible to the naked eye. Homogenizers use mechanical shear and high pressure to disperse even coarse particles, enhancing consistency and bioavailability in chemical, biotech, and lab applications.

Understanding how homogenizers process different mixtures clarifies their value across industries. The technology breaks down particles into extremely small sizes while preventing agglomeration, resulting in stable products with improved physical properties.

The homogenizer valve is crucial for efficiency and quality. Early designs used capillary tubes and concave valve seats, while modern high-pressure models employ advanced configurations like flat or multi-orifice seats for better control and energy efficiency.

Homogenization relies on three core principles:

- Shearing

- Cavitation

- Turbulence

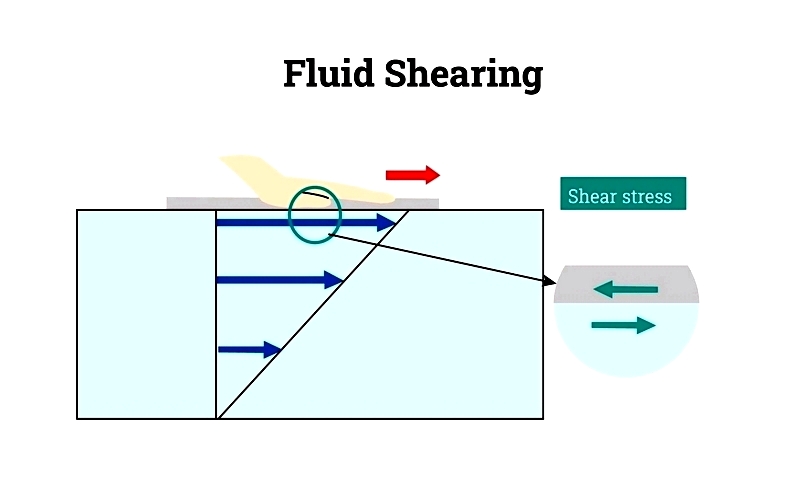

Shearing occurs when adjacent fluid layers move at different speeds, stretching and breaking particles. This improves dispersion for stable emulsions and suspensions in pharmaceuticals and cosmetics.

Cavitation happens when fluid pressure drops below vapor pressure, creating bubbles whose collapse generates energy to break particles. This process enhances cell lysis and size reduction in biotech applications.

Turbulence creates chaotic fluid motion with eddies that physically break up particles. The degree of turbulence affects final particle size and product consistency in food processing and pharmaceuticals.

The relative importance of these principles depends on factors like valve design, pressure, viscosity, temperature, and feed composition. While turbulence usually dominates in high-pressure systems, alternative technologies like ultrasonic homogenizers may emphasize different mechanisms.

Other homogenizing technologies—including ultrasonic systems, bead mills, and high-shear mixers—can achieve similar results through different mechanical actions. Selecting the right equipment and parameters ensures optimal product quality and processing efficiency for each application.