Introduction

This article provides an in-depth exploration of sheet metal fabrication.

You'll discover key topics including:

- What sheet metal fabrication is

- Various sheet metal fabrication techniques

- Different types of metals used in sheet metal fabrication

- Equipment for sheet metal fabrication

- Tools used in sheet metal manufacturing

- Applications of sheet metal

- And much more...

Chapter 1: What is Sheet metal Fabrication?

Sheet metal fabrication is a manufacturing process that shapes thin, flat metal sheets through cutting, bending, punching, and welding to create various forms. This technique works with multiple metals including brass, steel, copper, tin, titanium, and aluminum. Precious metals like platinum, gold, and silver are often used for decorative purposes. Sheet metal comes in different thicknesses, ranging from extremely thin foil to plates thicker than 6 mm. Thickness is measured by gauge, with lower numbers indicating thicker material (from 30 gauge for thin sheets to 8 gauge for thicker ones).

At its core, sheet metal fabrication transforms metal sheets into functional components through cutting, bending, or stretching. This process can create holes, two-dimensional shapes, and complex contours through various deformation methods.

Fabricators typically start with metal sheets produced by rolling processes, supplied as standard flat rectangles. Thin, long sheets often come in rolls. The first fabrication step involves cutting a 'blank' from these larger sheets to the required shape and size.

Sheet metal products serve numerous industries including construction, automotive, aerospace, consumer goods, furniture, and HVAC systems.

Chapter 2: Sheet metal Fabrication Techniques

Fabricators use specialized processes to shape metal sheets into finished products for industries like automotive, aerospace, construction, and electronics. Key fabrication methods include cutting, forming, stamping, and bending. Mastering these techniques is essential for producing high-quality, precise components for custom fabrication, mass production, and specialized applications.

Sheet metal Fabrication: Cutting

Cutting is a fundamental subtractive process where material is removed from metal sheets to create specific shapes. This technique uses both manual tools and automated CNC machinery like laser cutters and waterjets.

Sheet metal cutting falls into two categories: shear cutting and non-shear cutting. The choice depends on precision requirements and material characteristics for projects ranging from prototypes to full production.

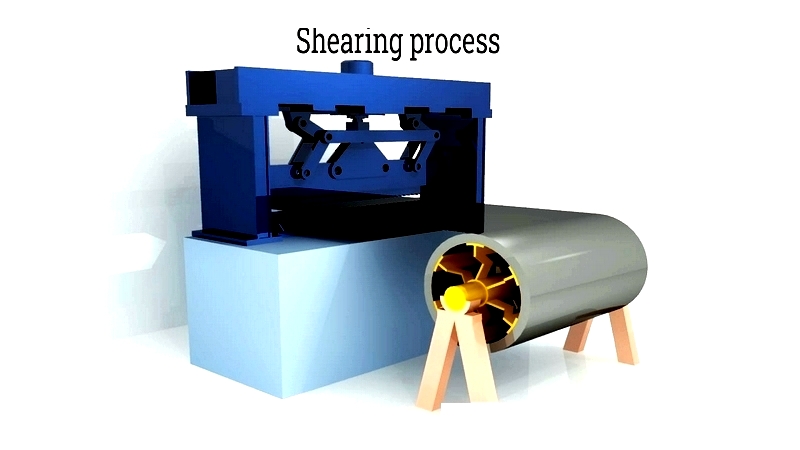

Shear Cutting

Shear cutting includes basic cutting, shearing, and blanking. These methods efficiently divide metal sheets into sections. While less precise than other methods, they offer cost-effective solutions for simpler applications where tight tolerances aren't critical.

Basic cutting uses a blade to segment sheet metal, either as an initial step or standalone process. Shearing employs paired blades (one moving, one stationary) to produce clean, burr-free edges across various gauges. It minimizes waste and works well for high-volume production while maintaining material integrity at ambient temperatures.

Blanking uses a die and punch to create precise holes or shapes in metal sheets. This stamping process is essential for parts with repetitive patterns like brackets and enclosures. It optimizes material use and can produce reusable blanks, reducing costs and supporting sustainability.

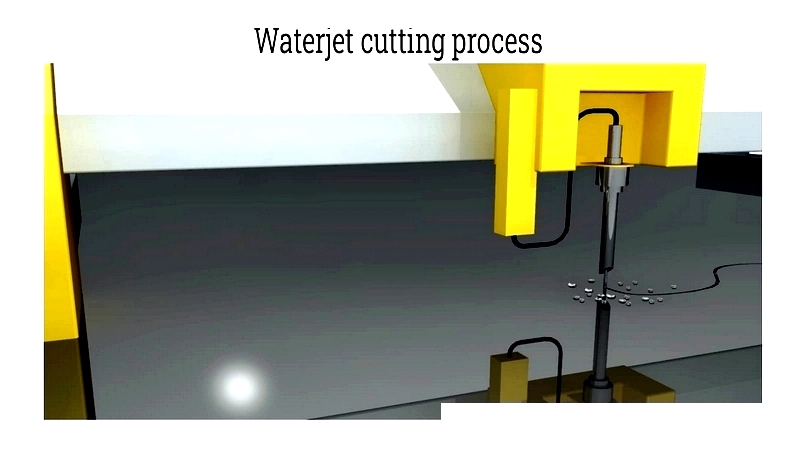

Non-Shear Cutting

Non-shear methods offer superior accuracy and finish, making them ideal for precision industries like aerospace and medical devices. Common techniques include laser cutting, waterjet cutting, plasma cutting, and machining.

Laser Cutting uses a focused laser beam to slice through metal with narrow kerfs and tight tolerances. This automated process works best with thin to medium sheets and produces minimal waste.

Waterjet Cutting employs a high-pressure water stream (often with abrasives) to cut without heat. This cold-cutting method prevents thermal distortion and handles thick sheets and sensitive materials well.

Plasma Cutting uses superheated gas to cut conductive metals quickly. While slightly less precise than other methods, it's cost-effective for thick materials and structural work.

Machining removes material with rotating tools to create complex features difficult to achieve through other methods.

Punch Press technology rapidly punches holes or cutouts in sheet metal. CNC punch presses enhance repeatability for electrical panels and enclosures.

Selecting the right cutting method depends on material thickness, tolerances, volume, and application requirements.

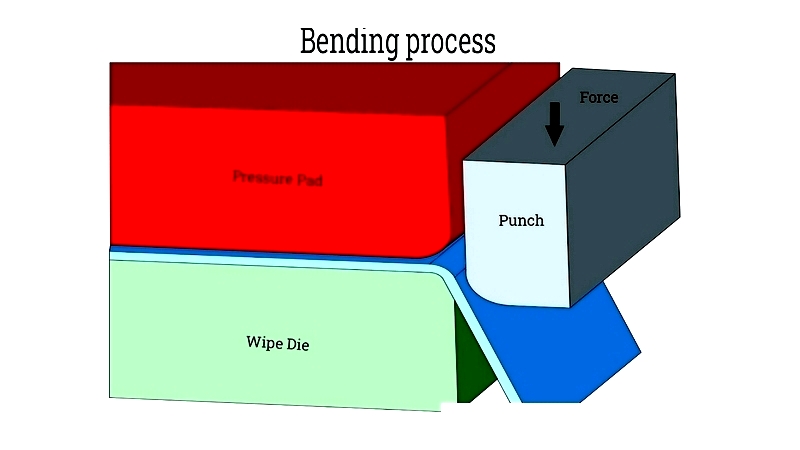

Sheet metal Fabrication: Forming

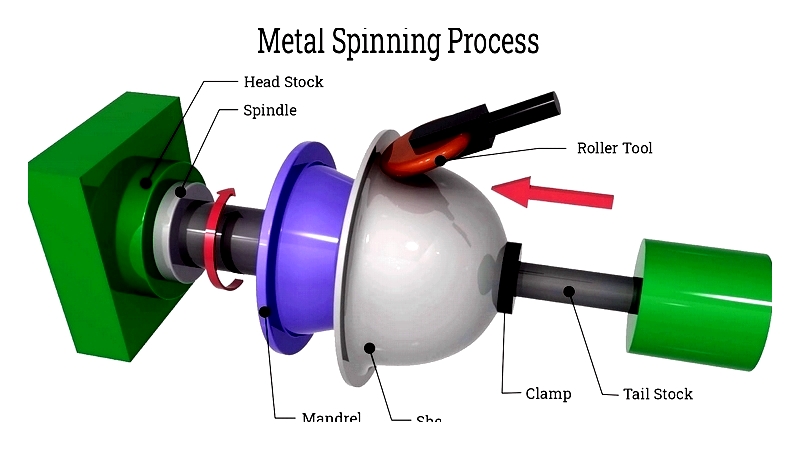

Forming reshapes metal without removing material, creating desired contours and properties. Processes include bending, stamping, roll forming, stretching, and spinning—each suited to different designs and production scales.

Bending uses press brakes to create precise angles in metal sheets for products like enclosures and brackets. CNC press brakes achieve tight tolerances across various metals and gauges.

Panel Bending efficiently produces large, complex components. Automated systems reduce labor and increase output for cabinet and enclosure manufacturing.

Stamping uses presses to deform metal in dies, ideal for high-volume parts like automotive panels and electronic chassis.

Stretching forms large contours for applications like aircraft skins and architectural elements.

Spinning shapes rotating blanks against mandrels to create seamless, symmetrical parts like cones and cylinders.

Choosing the right forming technique reduces waste, improves flexibility, and ensures quality compliance.

Sheet metal Fabrication: Assembly

Assembly joins components into finished products using methods like welding, riveting, brazing, and adhesives.

Welding fuses metals with heat, creating durable joints. Techniques include MIG (versatile) and TIG (precise for thin materials). Automation enhances consistency in large-scale production.

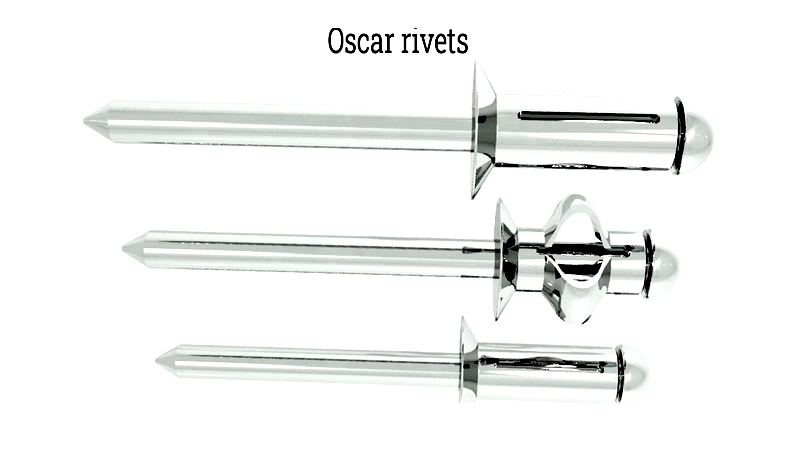

Riveting mechanically fastens sheets where welding isn't suitable. Types include:

- Drive rivet: Quick fastening with a mandrel

- Oscar rivet: Split shafts for better retention

- Blind rivet: Installed from one side

- Flush rivet: Smooth, aerodynamic finish

- Friction-lock rivet: High-stress applications

- Solid rivet: Demanding structural uses

- Self-piercing rivet: No pre-drilled holes needed

- Structural steel rivet: Largely replaced by bolts

Brazing bonds dissimilar metals effectively