Introduction

This section covers transparent cleanroom descriptions, types, and a list of manufacturers.

You will learn about:

- See-through cleanroom basics

- Different types of see-through cleanrooms

- Applications of see-through cleanrooms

- Construction methods for see-through cleanrooms

- Classification systems for see-through cleanrooms

- Additional important information

Chapter 1: Understanding See-Through Cleanrooms

See-through cleanrooms provide controlled environments where observers can monitor personnel activities without compromising cleanliness. These specialized cleanrooms feature various viewing options - including viewports, windows, and panels - whose designs depend on the cleanroom's ISO classification. Higher-class cleanrooms (ISO class 1) require maximum sealing on all viewing components, while lower classifications (ISO class 5+) permit more viewing port variations with different sealing materials.

Viewing port materials range from vinyl and plastics to thick glass, selected according to ISO standards. More stringent classifications demand sturdier, better-sealed materials. Mobile and modular cleanrooms typically use clear vinyl or plastic sheets and achieve ISO classifications between 5 and 8.

See-through cleanroom designs vary based on ISO classification and intended use. Common configurations include glass walls, vinyl strip soft walls, viewing ports, and various plastic materials like polycarbonate and PETG. Regardless of material choice, all feature durable walls, windows, pass-throughs, and viewing components.

Chapter 2: See-Through Cleanroom Varieties

Cleanrooms are primarily classified by ISO 14644-1 standards or FED STD 209E, which define permissible airborne particulate levels. While construction materials matter, the classification ultimately determines cleanliness levels and suitable applications.

See-through cleanrooms are categorized by their wall types, ranging from soft plastic sheet walls to solid glass or heavy-duty plastic walls. Visibility remains the key factor across all types, with material choices affecting viewing clarity. Lower ISO classifications (below class 3) demand exceptionally clear materials for proper observation.

Strip Curtain Cleanrooms

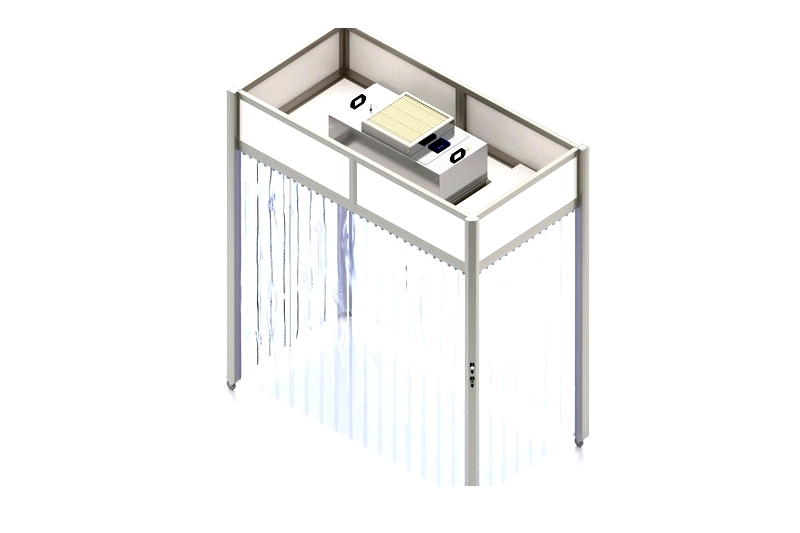

Strip curtains form cleanroom barriers using non-particulating materials. These softwall components allow external observation and typically feature 12-inch wide overlapping vinyl strips with 2-inch overlaps. Commonly used at entrances, they prevent ambient air contamination while maintaining visibility.

Their flexible design enables quick assembly and mobility, making them ideal for examining large equipment. However, vinyl material proves difficult to clean and has limited durability. Hung six inches above floors for air circulation, they're best suited for ISO class 7 or 8 applications where only large particulates need control.

Rigidwall Cleanrooms

Rigidwall cleanrooms represent an upgrade from strip curtain versions, featuring clear PVC, acrylic, or polycarbonate panels on frames. These achieve ISO classifications between class 4 and 8, with sizes ranging from 6x8x8 feet to 12x12x8 feet. Prefabricated panels are assembled on-site within 2-3 days.

Offering durability and easy cleaning, rigidwall cleanrooms provide stable testing environments with modular crystal-clear panels. They serve as cost-effective alternatives to premium hardwall cleanrooms while maintaining similar performance characteristics.

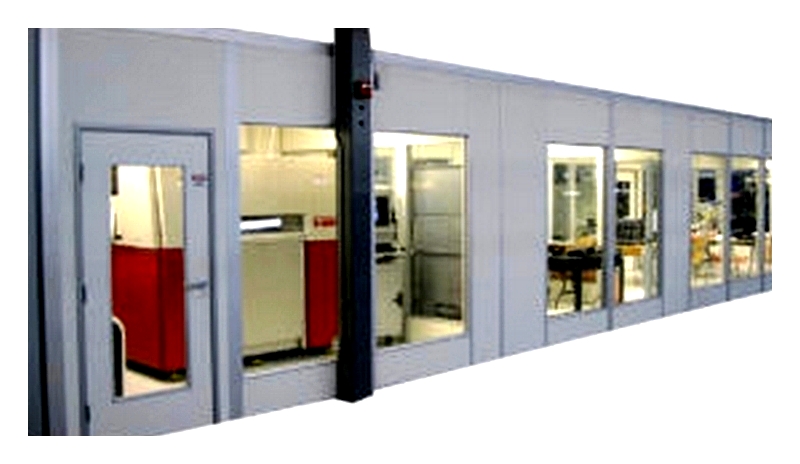

Glass Cleanrooms

Glass cleanrooms offer superior visibility for observing processes without entry. Typically combining glass panels with other wall systems, they feature quarter-inch tempered glass connected to stainless steel frames. Their stability and sealing achieve ISO class 5 ratings.

Available in various configurations, glass cleanrooms provide chemical resistance and easy decontamination. Stainless steel structural support reduces glass panel tension, while optional pass-through chambers allow material transfer without contamination risk.

Hardwall Cleanrooms

Permanent hardwall cleanrooms offer the highest ISO classifications with exceptional cleanliness control. Featuring rigid walls with strategically placed, sealed windows, they provide durability and precise environmental regulation. Modular versions offer some flexibility while maintaining high standards.

Regular inspections ensure compliance with strict ISO requirements. Their easy-clean surfaces and ability to accommodate existing equipment make them popular despite requiring significant space.

Cleanroom Windows

Cleanroom windows serve dual purposes: enabling observation and improving work environments. Available in various styles, they typically use tempered glass or impact-resistant alternatives like polycarbonate. Flush-mounted designs simplify cleaning, while semi-flush versions with rubber edges suit less stringent classifications.

Chapter 3: See-Through Cleanroom Construction

Modular see-through cleanrooms dominate the market, with classifications ranging from ISO class 3 to 8. Their transparent wall panels - made of glass or durable plastics - enable interior viewing while maintaining environmental controls. Steel or aluminum framing supports these structures.

Framing Systems

Steel framing provides necessary strength for supporting cleanroom components and maintaining ISO standards. Aluminum alternatives, particularly grade 6063-T6, offer sufficient support for certain applications while providing chemical resistance. Careful design ensures structural integrity and cleanliness maintenance.

Wall Panel Options

Vision panels maintain visibility while meeting strict ISO requirements. Glass offers superior containment but costs more, while plastic sheets provide flexibility for modular designs. All options feature seamless surfaces to prevent contaminant accumulation.

Plastic panels (PVC, polypropylene, or fiberglass-reinforced) offer smooth, chemical-resistant surfaces ideal for modular cleanrooms. Their clarity enables full-height observation without compromising cleanliness standards.

Panel Configuration Types

Stick Built: Constructed on-site with steel studs, these permanent cleanrooms allow custom geometries and future expansions. Viewing options range from traditional windows to full transparent walls.