Introduction

This article provides concise information about portable cleanrooms and their applications.

You will explore topics including:

- What is a Portable Cleanroom?

- How Portable Cleanrooms are Constructed

- Types of Portable Cleanrooms

- Applications of Portable Cleanrooms

- Benefits of Portable Cleanrooms

- And More...

Chapter One – What is a Portable Cleanroom?

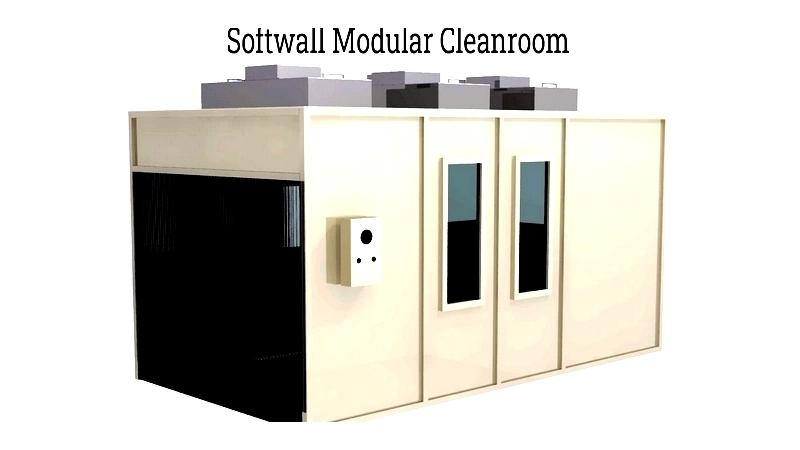

Portable or modular cleanrooms are pre-built, self-contained systems that only require electrical power and cooling to operate. Most designs can be delivered within 4-8 weeks and are engineered for quick assembly, typically taking one to three weeks to install.

Prefabrication enables rapid installation, significantly reducing operational downtime and contamination risks. Since these cleanrooms are manufactured in factories, they often eliminate the need for architects, engineers, or general contractors, resulting in substantial time and cost savings.

Some portable cleanrooms feature wheels or casters for mobility, while others are shipped as modular sections on pallets. When disassembled and relocated, 90-95% of components remain reusable. This reusability enhances cost-effectiveness, with certain designs like modular hardwall systems qualifying for accelerated depreciation benefits.

These cleanrooms meet ISO cleanliness standards ranging from 8 to 5, or Federal Standard Class 100 to 100,000. While functioning as standalone units, they can also create clean zones within existing cleanrooms. Their compact size, mobility, affordability, and ability to provide filtered air make them ideal for research, development, and product innovation, ensuring a controlled, contaminant-free environment.

Portable cleanrooms primarily control airborne particles including dust, microbes, aerosols, and chemical vapors to maintain compliance with established standards. HEPA filters are essential, capturing 99.97% of particles as small as 0.3 microns. For perspective, 1 micron equals 1/25,000 inch (0.04 inch), while 0.3 microns measures about 1/75,000 inch (0.001 inch). HEPA filtration ensures continuous air purity.

For ultra-clean environments like ISO 3 or Class 10, ULPA filters may be used. These remove 99.9995% of particles down to 0.12 microns. While similar in appearance to HEPA filters, ULPA filters use different media. Both types maintain ultra-clean air by capturing airborne contaminants.

Chapter Two – How Portable Cleanrooms are Made

Cleanrooms are vital in scientific, pharmaceutical, biotech, and electronics industries for developing and testing sensitive equipment, medicines, and chemicals that require protection from contaminants. Every design aspect receives meticulous attention to maintain regulatory compliance and product quality in these controlled environments.

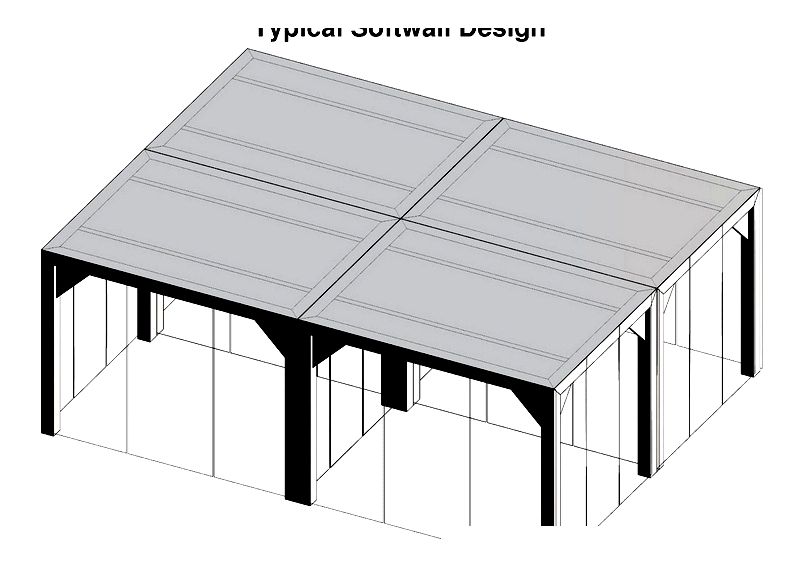

Portable cleanrooms have grown in popularity due to their cost efficiency, flexibility, and faster installation compared to traditional construction. Available in sizes from small mobile units to expandable modular systems, they can adapt to changing production needs or classification requirements. Many feature open plenums for flexible ISO upgrades. Custom options include ESD surfaces, chemical-resistant materials, antimicrobial finishes, and UV protection, making them suitable for manufacturing, research, and medical applications.

Cleanroom Rating and Classification

Determining the proper cleanroom classification is fundamental to installation and validation. Portable cleanrooms must meet the same ISO standards and particle counts as permanent structures. Validation involves testing air quality against strict standards for specific particle sizes and concentrations.

ISO 14644-1 requires 1-minute sampling of 1 cubic meter of air for particle measurement. The obsolete Federal Standard 209E used 1 cubic foot samples, requiring conversion (multiply counts by 35.315). ISO classifications range from ISO 1 (cleanest) to ISO 9, with most portable cleanrooms falling between ISO 5 and 8. Medical devices, semiconductors, and nanotechnology typically require stricter controls.

While Federal Standard 209E is outdated, many industries still reference it alongside ISO standards. The table below compares both systems' particle size allowances. Lower classification numbers indicate cleaner environments, with ISO 3 or Class 1 reserved for highly sensitive work.

When selecting cleanrooms or preparing for validation, consider end-user requirements, regulatory mandates (like FDA or GMP), and process sensitivities. Needs vary significantly between pharmaceutical sterility, electronics manufacturing (requiring ESD and particle control), and biotech research.

Proper classification ensures contamination control, regulatory compliance, and product integrity. Consult cleanroom manufacturers or ISO specialists to determine the right environment for your needs.

Cleanroom Temperature and Humidity Control

Temperature and humidity control are critical for process stability, microbial control, and equipment performance. Requirements vary by application: pharmaceuticals need strict limits to prevent bacterial growth, while electronics focus on static control.

Many applications tolerate ambient conditions, but regulated environments typically maintain