Introduction

This article provides an in-depth exploration of electrical plug types.

Continue reading to learn about:

- What Electrical Plugs Are

- Two-pronged vs Three-pronged Plugs

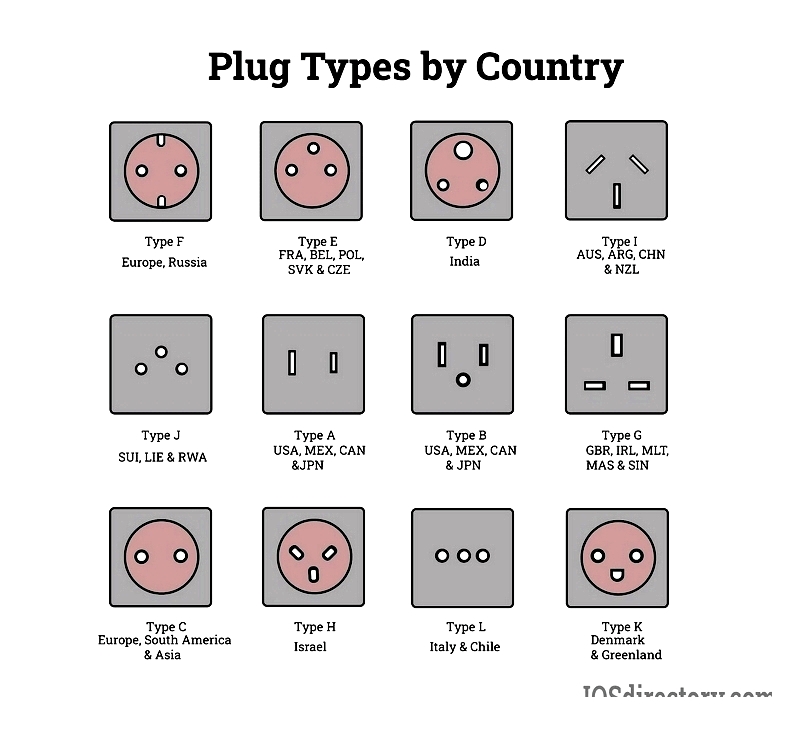

- Different Types of Electrical Plugs

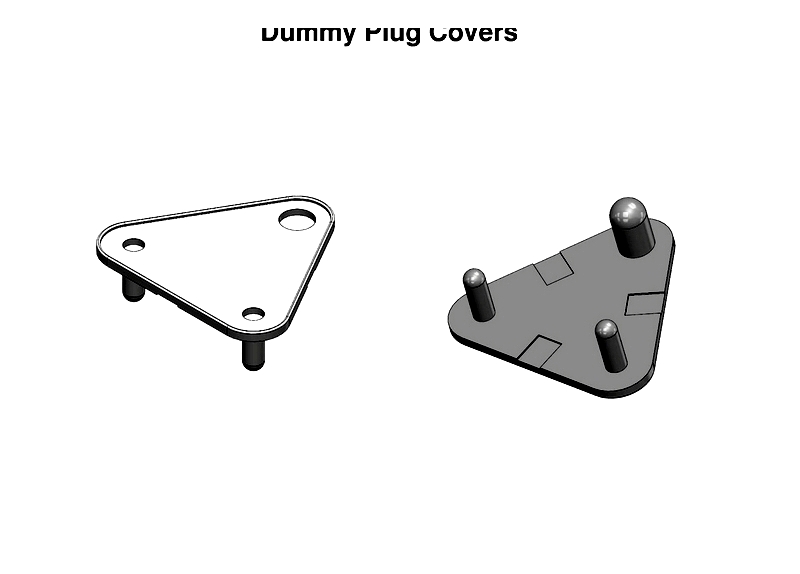

- Plug Adapters and Replacement Options

- And more...

Chapter 1: What Are Electrical Plugs?

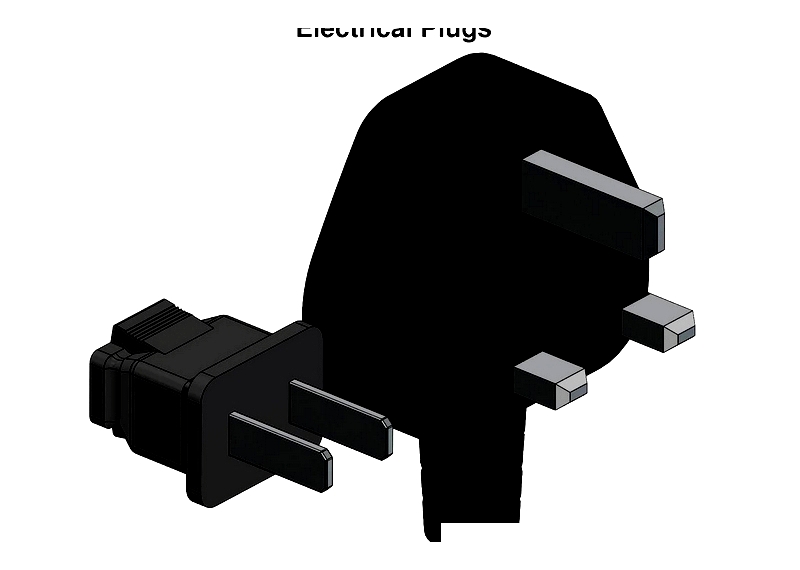

Commonly called power plugs, electrical plugs enable the transfer of electrical current from outlets to appliance circuits.

These plugs feature prongs or pins encased in plastic housings that securely connect to outlet sockets, establishing a reliable link between devices and power sources.

Globally available in various designs, standard electrical plugs serve residential, industrial, and commercial needs. Their configurations vary in pin count, size, voltage, and current specifications, often determined by regional standards.

Chapter 2: Two-Pronged vs Three-Pronged Plugs: Key Differences

Electrical plugs play a vital role in safely operating household and industrial devices, with two or three prong configurations meeting different safety needs. Recognizing these differences ensures proper installation, code compliance, and user protection.

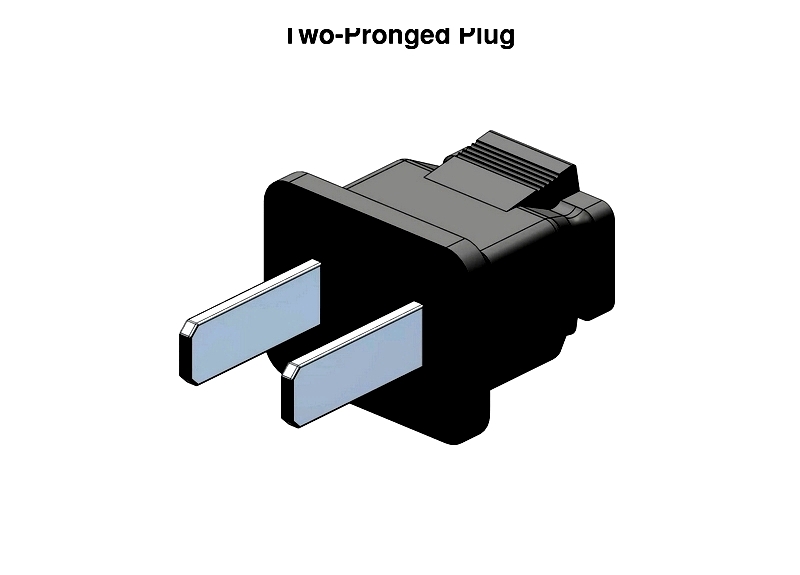

Two-Pronged Plugs

Common in many households, two-pronged plugs power double-insulated or low-wattage devices. They feature a live ("hot") prong that draws current and a neutral prong that completes the circuit. These plugs fit standard two-slot outlets and typically power lamps, chargers, and small appliances.

While compact and convenient, their lack of grounding makes them unsuitable for high-power devices. Without a ground path, electrical faults could potentially cause shocks or equipment damage.

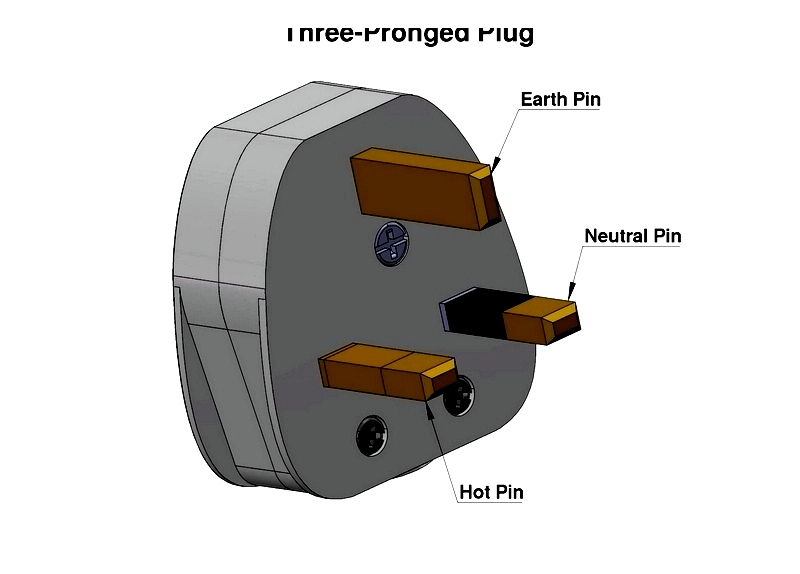

Three-Pronged Plugs

Featuring an additional grounding pin, three-pronged plugs meet modern safety standards. The ground pin provides a safe path for stray electricity during faults, reducing shock and fire risks while protecting sensitive electronics.

Essential for high-wattage appliances and metal-cased equipment, these plugs comply with NEC and international safety standards. Modern installations typically require grounded outlets to accommodate them.

Selecting the Appropriate Plug

Choosing the right plug involves considering device requirements, safety codes, and compatibility:

- Power Needs: Three-pronged plugs suit high-power devices; two-pronged versions work for low-power, insulated equipment

- Safety Compliance: Follow current electrical codes to prevent hazards

- Outlet Compatibility: Never modify plugs to fit incompatible outlets

Understanding these differences safeguards both equipment and electrical systems. For complex projects, consult certified electricians and reputable manufacturers for quality components.