Introduction

This guide covers everything you need to know about NEMA Connectors.

You will learn about:

- What NEMA Connectors are

- NEMA Plugs, Power Cords, and Receptacles

- NEMA Enclosures

- International Standards for Power Cords and Receptacles

- And much more…

Chapter One – Understanding NEMA Connectors

NEMA connectors are crucial for connecting electronic devices to power sources, supporting both alternating current (AC) and direct current (DC). AC is typically used in homes, offices, and commercial spaces, while DC usually comes from batteries.

Household connectors often have two or three prongs, but the global industry uses hundreds of different types. Each is designed for specific amperage (A) and voltage (V) requirements.

In the U.S., connectors are rated for currents from 15 to 60 amps and voltages from 125 to 600 volts. They come in various configurations with different blade shapes, sizes, and arrangements to prevent mismatching, ensuring they meet specific voltage, current, and grounding needs.

All U.S. manufacturers follow NEMA standards, ensuring industry-wide consistency. NEMA standardization defines plug and receptacle pin configurations based on their amperage and voltage ratings.

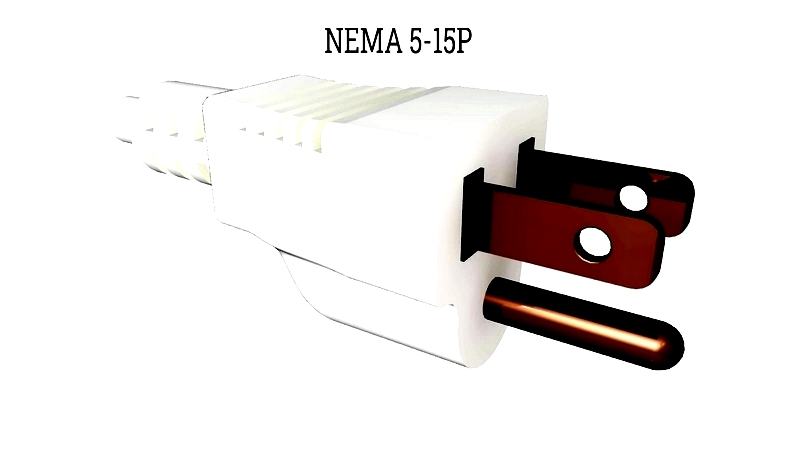

The diagram shows NEMA 2-20, NEMA 6-50, and NEMA 24-15 models, each with unique pin arrangements. These models differ in amperage and voltage, with 2-20 and 6-50 rated for 250V and 24-15 for 347V.

Chapter Two – Differences Between NEMA Plugs, Power Cords, and Receptacles

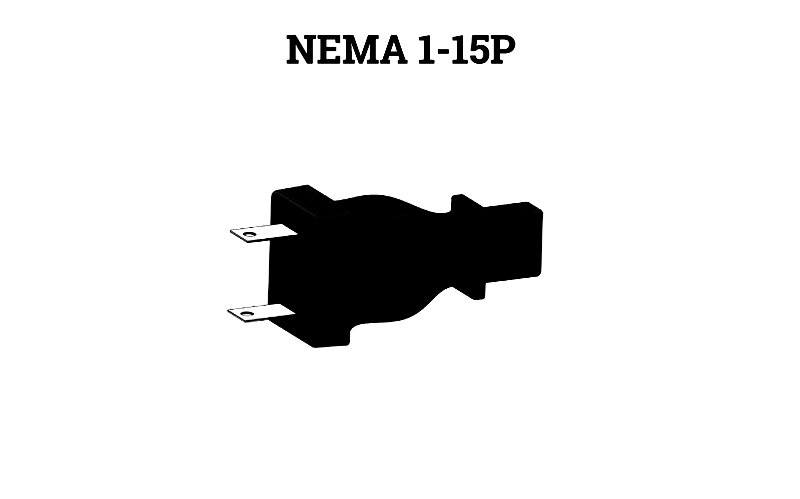

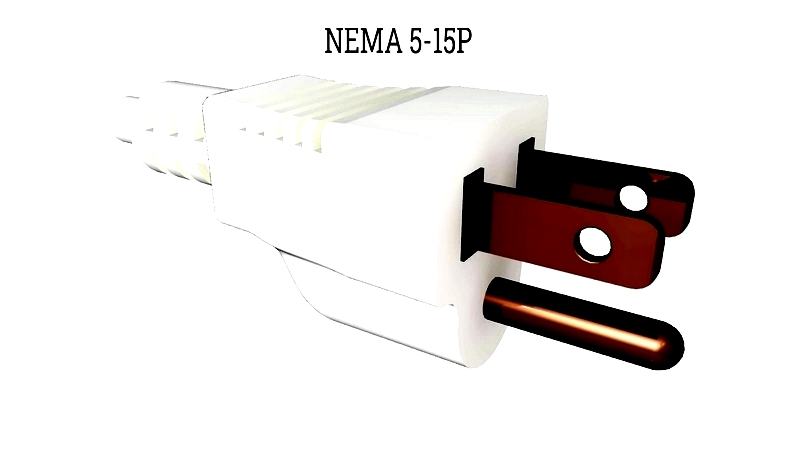

U.S. electrical plugs and receptacles are made to strict quality and safety standards set by the National Electrical Manufacturers Association (NEMA). Following NEMA standards ensures compatibility, reliability, and proper grounding in residential, commercial, and industrial settings. The most common NEMA connectors are NEMA 1-15P and NEMA 5-15P. These feature molded rubber housings and steel or brass prongs with zinc, tin, or nickel coatings for better conductivity and corrosion resistance. Many other NEMA power plugs and receptacles exist, each designed for different voltage, amperage, and application needs.

Connectors are divided into locking and non-locking types. Locking connectors have curved prongs that twist and lock into place, providing secure connections ideal for heavy-duty, high-vibration, or industrial use. Non-locking connectors, with their straight blades, are common for computers, office equipment, and small appliances. Choosing the right NEMA connector is essential for safe and consistent power distribution.

This chapter details the most common and important NEMA plug and receptacle types in residential and industrial settings, focusing on their electrical ratings, safety features, and applications.

Types of NEMA Connectors

Non-Locking

Among non-locking connectors, NEMA 1 and NEMA 5 are the most widely used in North America. NEMA 1 has two blades without a ground, suitable for low-power devices, while NEMA 5 adds a grounding pin for safety, meeting current National Electrical Code (NEC) requirements. Due to increased safety standards, most new construction now requires NEMA 5 receptacles, phasing out older NEMA 1 types.

The NEMA system uses the first number to indicate configuration, specifying poles, wires, and voltage. Options include grounded and non-grounded designs, like two-pole three-wire or four-pole five-wire. Non-grounded types match wire count to poles. Each connector includes an ampacity number followed by "P" (plug) or "R" (receptacle)—for example, a NEMA 5-15R is a 125V, two-pole, three-wire, 15-amp receptacle common in homes.

Standard installation places the ground pin upward in wall outlets. This layout prevents metal objects from touching live wires, reducing short-circuit risks and protecting users from shocks. Following NEMA codes is key for safe and efficient power delivery, especially where electrical disturbances must be minimized.

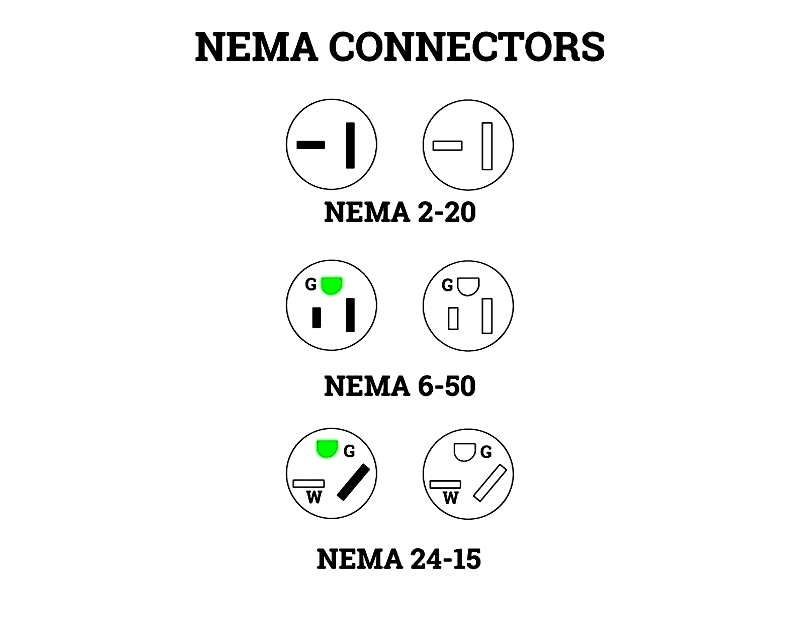

NEMA 1

NEMA 1 plugs have two flat prongs in a two-pole, two-wire, non-grounded 125V configuration. Used for lamps, chargers, and low-power devices, their use is declining due to lack of grounding. The most common type is NEMA 1-15P.

NEMA 2

The NEMA 2 series is obsolete, no longer produced. It was a two-wire, 250V system for limited historic uses.

NEMA 3

NEMA 3 is a planned series for high-voltage applications, with a two-wire, ungrounded 277V design for certain commercial lighting.

NEMA 4

The upcoming NEMA 4 series targets higher capacity needs, offering a 600V, two-wire, ungrounded design for future industrial use.

NEMA 5

NEMA 5 connectors feature two flat blades and a grounding pin in a two-pole, three-wire 125V design. Common ratings include NEMA 5-15, 5-20, and 5-30. These are standard for residential outlets and extension cords, supporting most small to medium appliances.

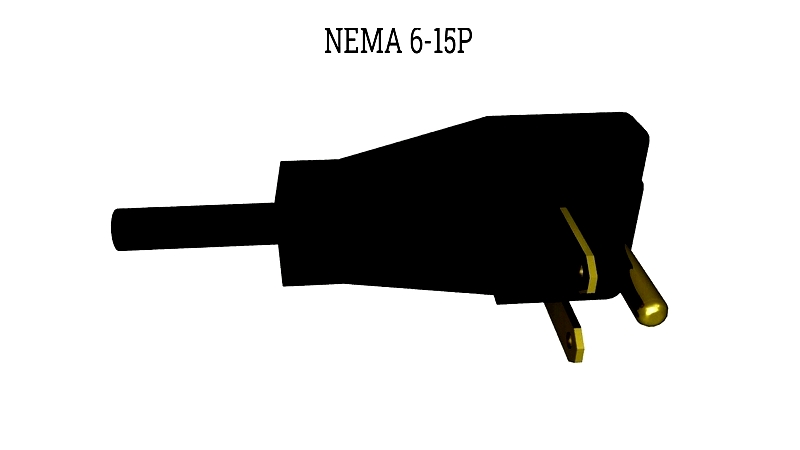

NEMA 6

NEMA 6 connectors are for higher voltage (208 or 240V) and heavy-duty use in commercial and industrial settings. Their three-wire grounded design powers large equipment like HVAC units, air compressors, and kitchen appliances.

NEMA 7

NEMA 7 provides a two-pole, grounded 277V design, often used for single-phase fluorescent lighting. It has angled pins and a U-shaped ground for safety.

NEMA 8

NEMA 8 is a proposed 480V, three-wire, two-pole grounded connector for specialized industrial equipment.

NEMA 9

NEMA 9 is similar to NEMA 8 but rated for 600V, meeting more demanding system needs.

NEMA 10

NEMA 10 connectors, now obsolete, were once used for dryers and ranges but have been replaced by grounded types like NEMA 14-30 and 14-50.

NEMA 11

NEMA 11 handles three-phase, 250V loads with three-pole, three-wire ungrounded designs in 20, 30, and 50 amp versions for legacy industrial equipment.

NEMA 12

NEMA 12 is an upcoming three-phase, 480V, three-wire, three-pole ungrounded connector for industrial applications.

NEMA 13

NEMA 13 matches NEMA 12 but is rated for 600V, targeting heavy industrial needs.

NEMA 14

NEMA 14 is a four-wire grounded outlet with 15-60 amp ratings, used for