Introduction

This article provides a comprehensive overview of water chillers.

Continue reading to explore key topics including:

- What is a water chiller?

- How water chillers work

- Different types of water chillers

- Design considerations

- And more...

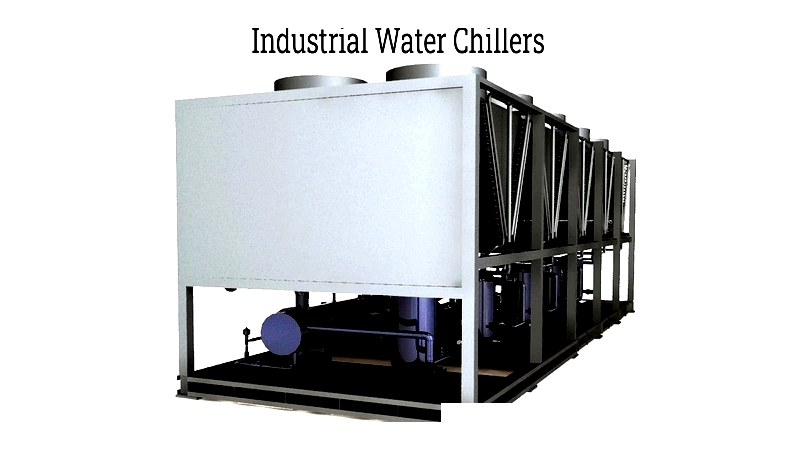

Chapter 1: What is a Water Chiller?

A water chiller, also known as a chilled water system, is a refrigeration system that uses water as a secondary refrigerant. These systems are commonly employed in complex HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) installations. Water chillers find applications in various industries, such as:

- District cooling

- Central air conditioning

- Hydroponics

- Food and beverage processing

- Pharmaceutical and medical industries

- Cold storage facilities

- Thermal Energy Storage (TES) systems

- Machining processes including waterjet cutting, laser cutting, and welding

- Plastic manufacturing

Unlike water chillers, direct-expansion (DX) refrigeration systems cool air directly without using a secondary refrigerant. In these systems, air passes over the evaporator to be cooled. DX systems are generally more suitable for smaller applications like residential cooling and compact refrigeration units.

Chapter 2: How Does a Water Chiller Work?

A water chiller system consists of two primary circuits: the refrigeration loop and the chilled water loop. Understanding these components is crucial for selecting the right industrial chiller for commercial HVAC, process cooling, or manufacturing applications. The refrigeration loop provides cooling through thermodynamic processes and refrigerant flow, while the chilled water loop distributes cold water to end-use equipment. Together, these loops enable efficient heat transfer, reduce environmental heat load, and optimize energy performance. Mastering their interaction is key to evaluating chiller performance, efficiency metrics (EER, COP), and suitability for specific cooling needs.

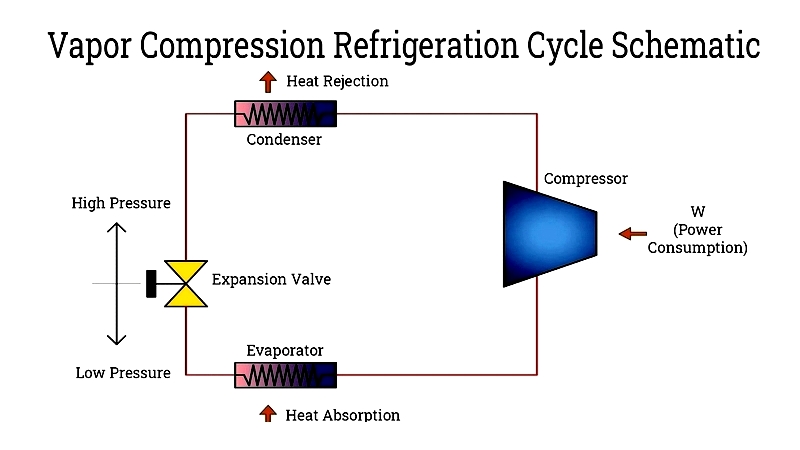

The Vapor Compression Cycle

The refrigeration loop operates on the vapor compression refrigeration cycle, the most widely used cooling technology in water-cooled and air-cooled chillers. In this cycle, a specialized refrigerant alternates between liquid and gas states, absorbing and rejecting heat through heat exchangers. Key components like compressors and expansion valves regulate refrigerant pressure and temperature. Understanding each step helps engineers properly size chillers, optimize energy use, and ensure reliable cooling for industrial applications.

Compression

The cycle begins with the refrigerant as a low-pressure vapor carrying heat from the evaporator, typically at ambient temperature.

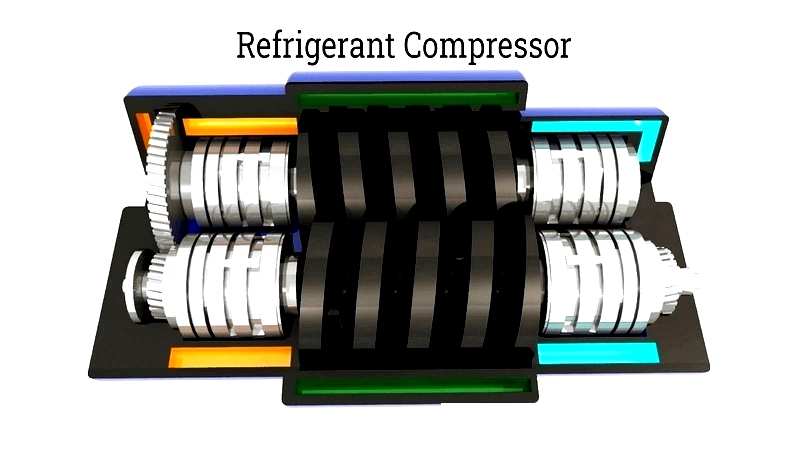

The compressor, often called the chiller's "heart," pressurizes the refrigerant vapor, increasing its pressure and temperature. Different compressor types (scroll, screw, centrifugal, reciprocating) are selected based on cooling capacity, efficiency, and application. The compressor's motor is a major energy consumer, directly impacting operating costs.

Increasing refrigerant pressure requires mechanical energy from the compressor, driving the rest of the cooling cycle.

Condensation

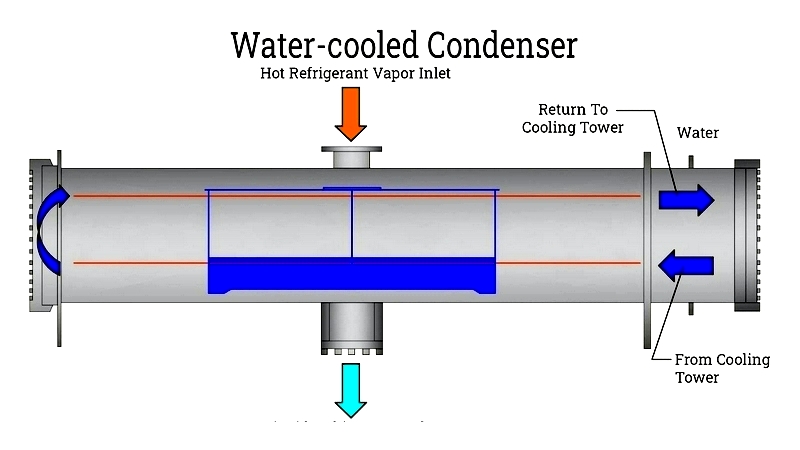

The condenser, a high-pressure heat exchanger, releases thermal energy to the environment. It transfers heat from the refrigerant to cooler ambient air or water, rejecting both absorbed heat and compression heat. This component is vital for overall chiller performance and efficiency.

The environment serves as the heat sink. Depending on chiller design, this may be outside air (air-cooled chillers) or a water loop/cooling tower (water-cooled chillers). Selection depends on factors like location, water availability, noise, and operating costs.

As heat is rejected, the refrigerant condenses back to liquid at its saturation point. Understanding saturation temperature is essential for system design and refrigerant selection (R134a, R410A, etc.), with implications for sustainability and compliance.

Expansion

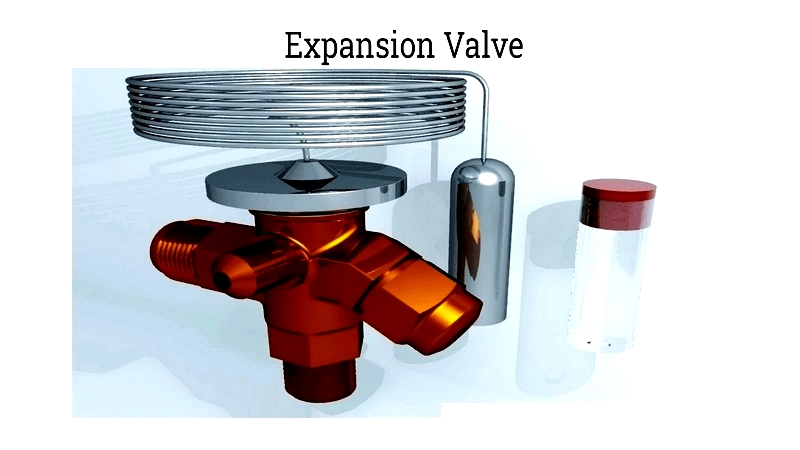

The high-pressure liquid refrigerant then passes through an expansion device (thermal expansion valve or capillary tube), where its pressure and temperature drop sharply. This expansion partially vaporizes the refrigerant, creating the cold temperatures needed for heat exchange in the evaporator. Minimizing heat gain during expansion maintains cooling efficiency.

The expansion device precisely controls refrigerant flow, ensuring stable operation and preventing issues like evaporator freeze-up. Proper selection and maintenance affect long-term reliability, especially under variable loads.

Evaporation

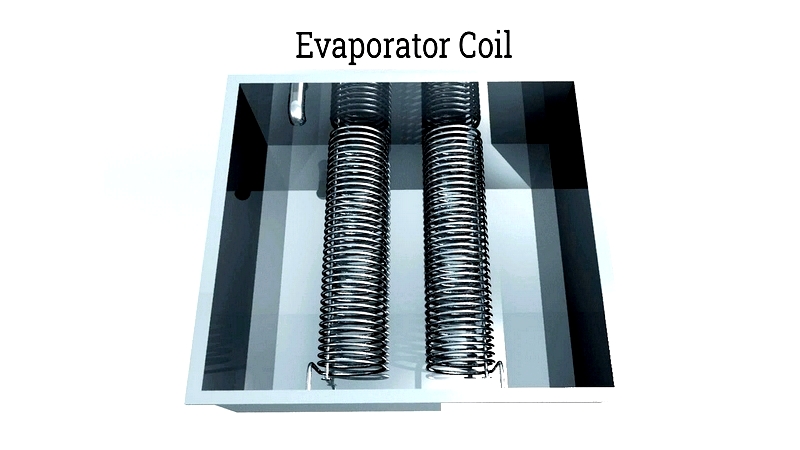

In the low-pressure evaporator, the refrigerant absorbs heat from chilled water or brine, lowering its temperature to the desired setpoint. This process supports cooling in commercial HVAC, food processing, plastic molding, and data centers.

During evaporation, the refrigerant changes phase by absorbing heat, effectively removing unwanted thermal energy. The resulting low-pressure vapor then returns to the compressor to restart the cycle.

Vapor compression chillers dominate over 90% of HVAC and process cooling installations due to their efficiency and precise temperature control. Alternative technologies like absorption cycles are used in specialized cases where waste heat is available, offering eco-friendly solutions for district cooling and CHP plants.

Absorption Chillers

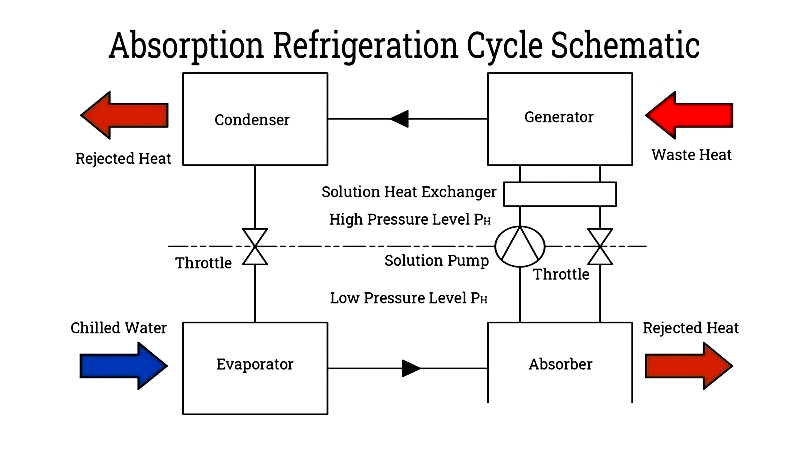

Absorption chillers use a thermochemical process instead of mechanical compression. Common working pairs (lithium bromide-water or ammonia-water) enable operation with minimal electricity by utilizing available heat sources. These systems are valued for reliability, environmental friendliness, and potential to reduce emissions, making them ideal for large-scale commercial and municipal applications seeking energy savings and sustainability.

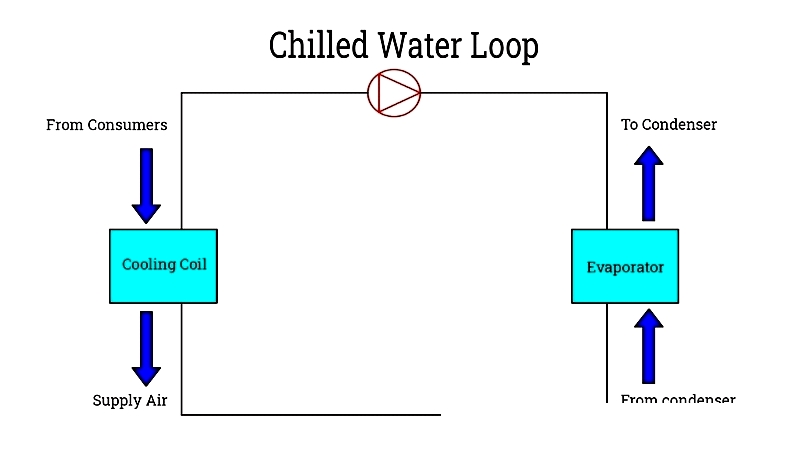

The Chilled Water Loop

The chilled water loop serves as the secondary heat transfer path, using water or water-antifreeze mixtures as the cooling medium. Chilled water circulates through air handlers or process equipment to remove heat, then returns to the evaporator for re-cooling. This centralized approach is essential for large facilities requiring stable temperature control.

For low-temperature applications, antifreeze agents (glycol, brine) prevent freezing in pipes. Modern options like ethylene and propylene glycol improve efficiency, prevent corrosion, and optimize heat transfer.

Liquid chillers using water-antifreeze mixtures are ideal for specialized low-temperature cooling. Proper fluid selection and pump speed are crucial for maintaining flow rates, minimizing energy use, and ensuring reliable performance