Introduction

This is the most comprehensive online guide to conveyor systems.

You'll discover:

- What conveyor systems are

- System requirements

- Different conveyor types

- How conveyor systems operate

- And much more...

Chapter One – Understanding Conveyor Systems

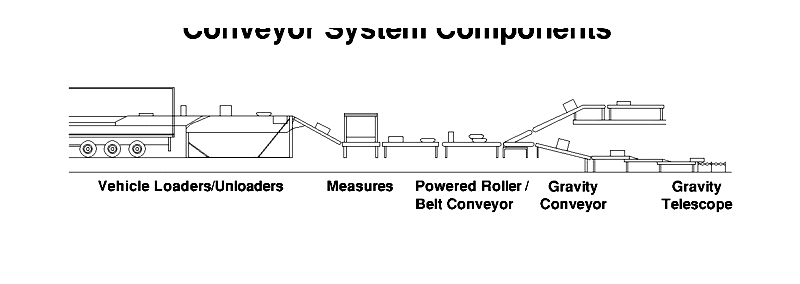

A conveyor system is mechanical equipment that transports packages, products, parts, and materials for manufacturing, distribution, or repositioning purposes. Common types include pneumatic, screw, belt, and roller conveyors. Each system's design depends on the materials' characteristics like weight, size, and mobility.

While essential for material handling, conveyor systems also serve manufacturing processes like sintering, finishing, and washing. Most operate automatically, though manual versions with chutes and rollers are common in retail, shipping, and material handling.

Chapter Two – Conveyor System Requirements

Conveyor systems enhance efficiency, productivity, and speed in various operations. Before installation, facility managers should evaluate several key factors. Each system is engineered for specific applications in industrial automation, warehousing, food processing, or packaging.

Space

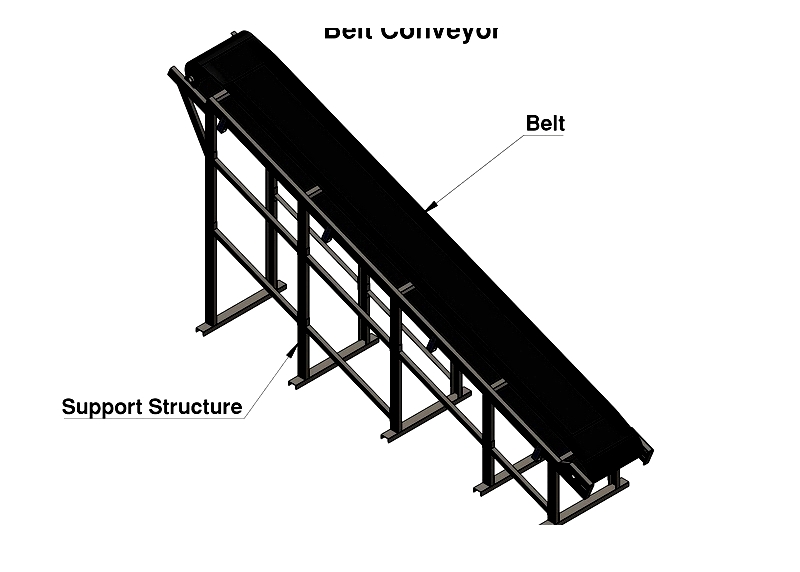

Manufacturers assess floor space and layout to optimize system design, considering equipment interactions, safety clearances, and workflow. Automated systems dominate modern facilities, but applications determine whether motorized, powered, or gravity-fed solutions are best. Space planning ensures proper integration of belt, roller, or overhead conveyors.

Load Capacity

Determining maximum capacity prevents belt slippage, wear, and failures. Key factors include conveyor length, bed width, item weight, drive torque, and material type. Proper calculations protect both equipment and products while meeting industry standards.

Speed

Measured in feet per minute (fpm), conveyor speed typically matches a person's walking pace (65 fpm). However, distribution centers may require higher speeds, while delicate processes need slower movement. Adjustable speeds help synchronize product flow throughout the system.

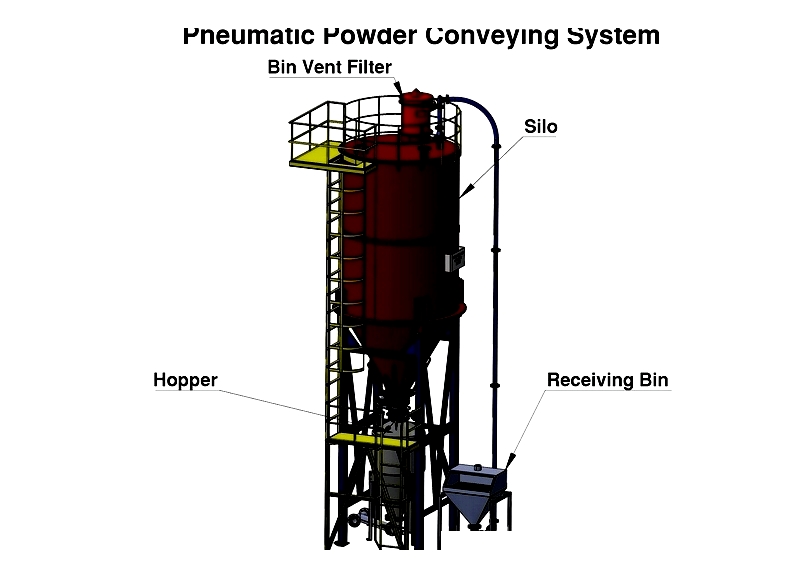

Powder or Liquid Handling

These materials require specialized sealed systems like pneumatic or screw conveyors to prevent leaks. Dust control and proper material selection are crucial for pharmaceuticals, chemicals, and food processing. Particle characteristics determine the safest transfer methods.

Configuration

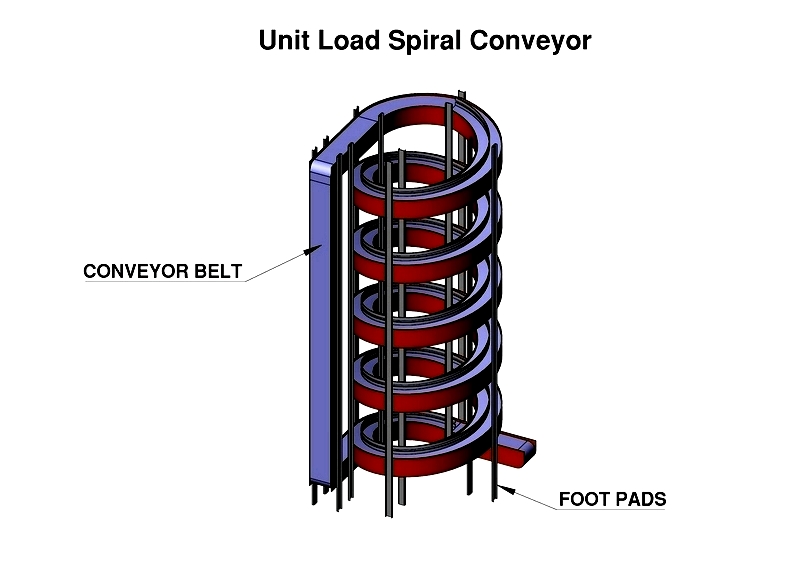

Conveyors come in vertical, horizontal, curved, or modular designs with specialized attachments. Custom configurations optimize space and workflow for specific applications like pallet handling or sortation.

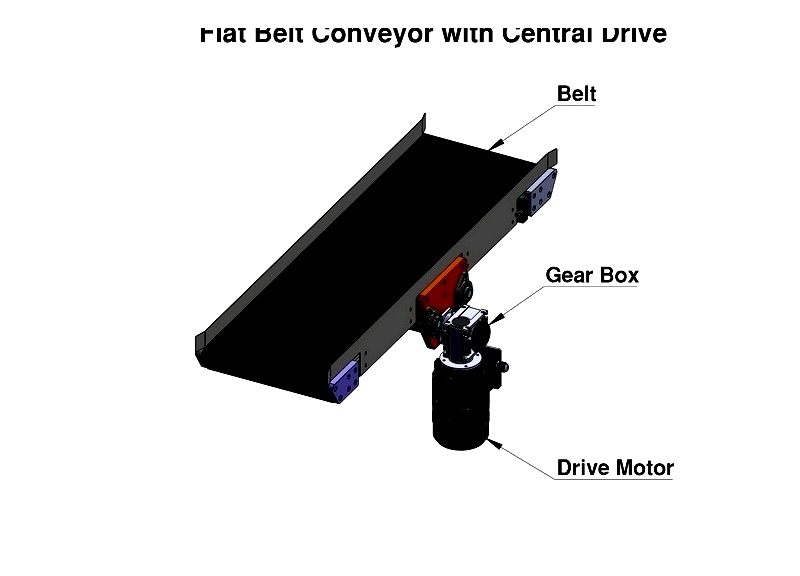

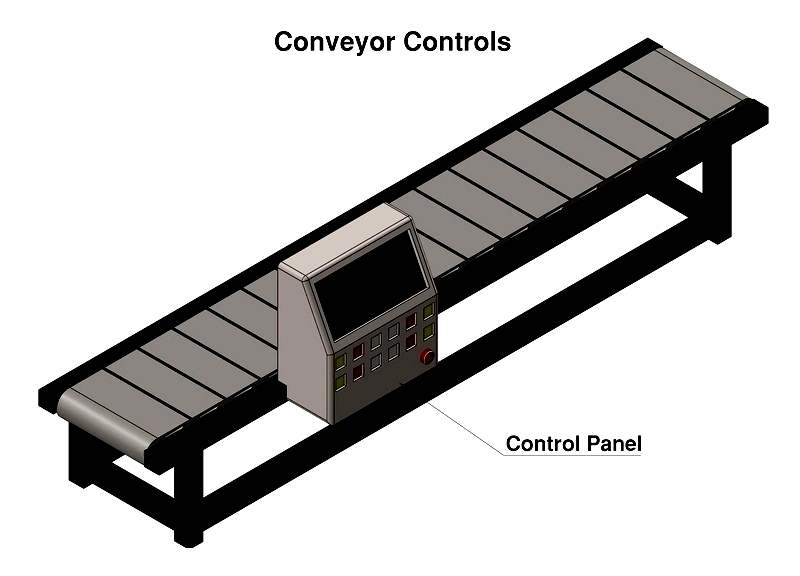

Drive System

The drive mechanism powers product movement using motors, gearboxes, and pulleys. Placement varies by system type, with options for forward/reverse operation. Modern systems use VFDs for precise speed control and energy efficiency.

Safety

Essential safety features include emergency stops, guards, and warning signs. Compliance with OSHA standards and proper training prevent accidents in high-volume environments.

Additional Considerations

evaluate environmental conditions, sanitation needs, scalability, and maintenance requirements. Energy-efficient designs and control system compatibility optimize long-term performance and ROI.