Introduction

This comprehensive guide covers everything you need to know about EMI and EMIF shielding.

Continue reading to explore:

- Fundamentals of EMI and EMIF Shielding

- How EMI Shielding Works

- Popular EMI Shielding Materials

- Designing Effective EMI Shielding

- Additional valuable insights

Chapter 1: Understanding EMI and EMI Shielding

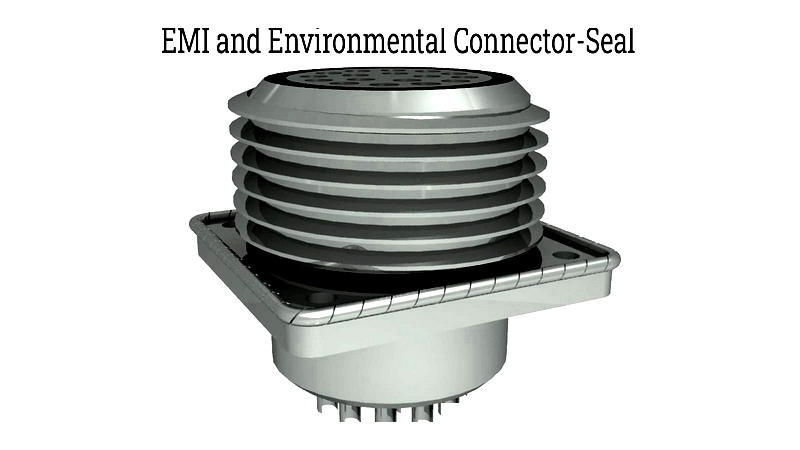

EMI shielding involves creating barriers to prevent strong electromagnetic fields from escaping and disrupting sensitive devices. This protection can isolate electromagnetic sources or enclose vulnerable equipment. Electromagnetic interference (EMI), sometimes called radio frequency interference (RFI), commonly affects electronic devices by impairing circuit performance and causing malfunctions. Modern electronics, operating with low voltages and currents, are particularly prone to electromagnetic disruptions.

Understanding Electromagnetic Interference (EMI)

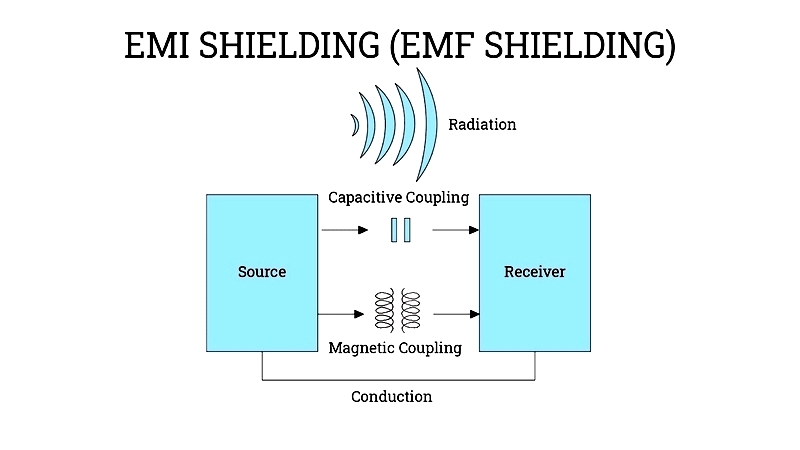

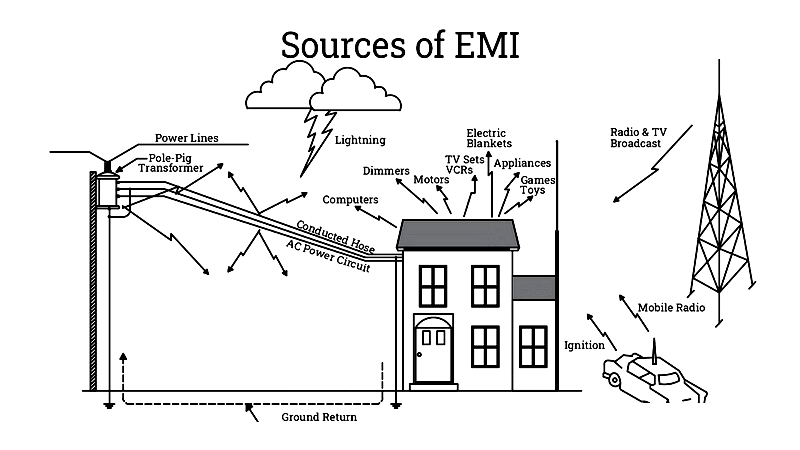

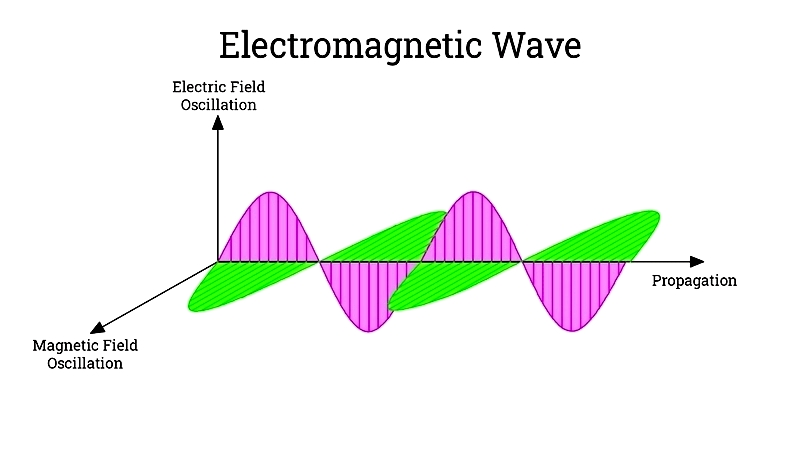

Electromagnetic interference (EMI) occurs when unwanted signals from one system affect another. EMI involves three key components: the source, transmission path, and receiver. Sources can be natural (lightning, solar flares) or man-made (power lines, radio waves). The receiver experiences signal distortion, while the transmission path facilitates this interference through various modes.

- Conducted EMI: Occurs when stray signals travel between circuits via conductive paths. It can be common-mode (shared grounding) or differential-mode (opposite current flow).

- Radiated EMI: Spreads through open space, with cables and PCB traces acting as unintentional antennas.

- Capacitive EMI: Results from parasitic capacitance between closely spaced conductors.

- Magnetic EMI: Caused by electromagnetic induction between nearby conductors with fluctuating currents.

Classifying Types of EMI

EMI can be categorized by duration: continuous or pulse interference. Continuous interference involves persistent low-energy signals like radio waves, while pulse interference consists of brief, high-energy bursts. It can be repetitive (predictable) or random (like lightning strikes).

EMI is also classified by bandwidth: narrowband (within receiver bandwidth) or broadband (exceeding receiver bandwidth).

The Significance of EMI Shielding

As technology advances, electronic devices must be shielded to prevent mutual interference. EMI shielding contains electromagnetic energy and protects devices from external disturbances. All electronics emit some electromagnetic energy and remain vulnerable to EMI.

EMI impacts electronics through direct contact, proximity, and distance. Growing reliance on electronics increases electromagnetic pollution. Potential effects include:

- Disrupted communication signals

- Power failures and voltage fluctuations

- Circuit damage or failure

- Reduced system efficiency

- Safety hazards like electric shocks

Global standards ensure electromagnetic compatibility (EMC). Organizations like CISPR, IEC, ISO, and the FCC establish these regulations to maintain device functionality in electromagnetic environments.

Chapter 2: Leading Machines for EMI Shielding

Specialized machines produce effective EMI shielding for today's digital landscape. These solutions are crucial for industries like telecommunications, aerospace, and medical devices. Below are key brands and their offerings:

Brand: Chomerics (Parker Hannifin)

Model: Electromagnetic Shielding Materials Manufacturing Equipment

Features: Advanced extruders, calendering machines, and precision coaters for conductive gaskets and foils. Supports high-volume production and custom solutions.

Brand: Schaffner Group

Model: EMI Shielding Solutions Manufacturing Systems

Features: metal stamping presses and injection molding systems for power line filters and contact strips. Includes real-time monitoring and automation.

Brand: Integrated Microwave Corporation (IMC)

Model: EMI/RFI Shielding Material Production Equipment

Features: Laminating machines and die-cutters for conductive foams and RF absorbers. Ideal for telecommunications and defense applications.

Brand: JEMIC Shielding Technology

Model: EMI Shielding Material Manufacturing Machines

Features: Coating systems and cutting machines for conductive textiles and tapes. Enables flexible production for medical and military uses.

Brand: Leader Tech Inc.

Model: EMI Shielding Material Manufacturing Equipment

Features: Molding presses and curing ovens for conductive elastomers and thermal pads. Suitable for aerospace and electronics.

When selecting EMI shielding equipment, consider material type, production process, and compliance standards. Consult manufacturers for tailored solutions.

Chapter 3: EMI Shielding Mechanisms

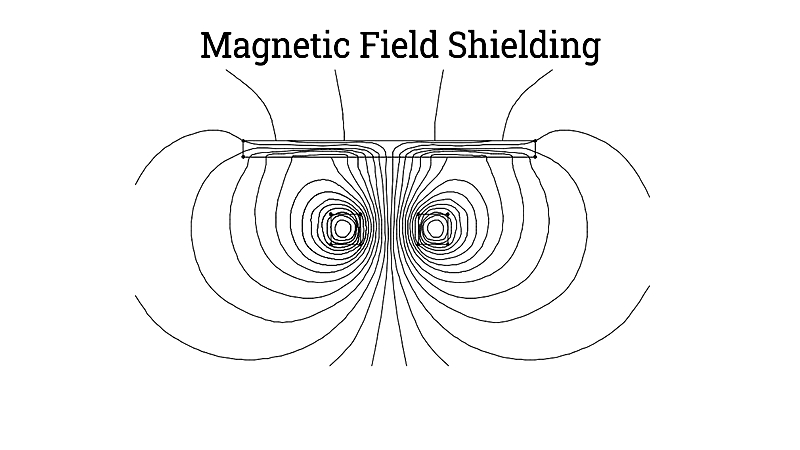

EMI shielding achieves electromagnetic compatibility by blocking or redirecting unwanted energy. It uses conductive or magnetic materials to absorb or reflect interference.

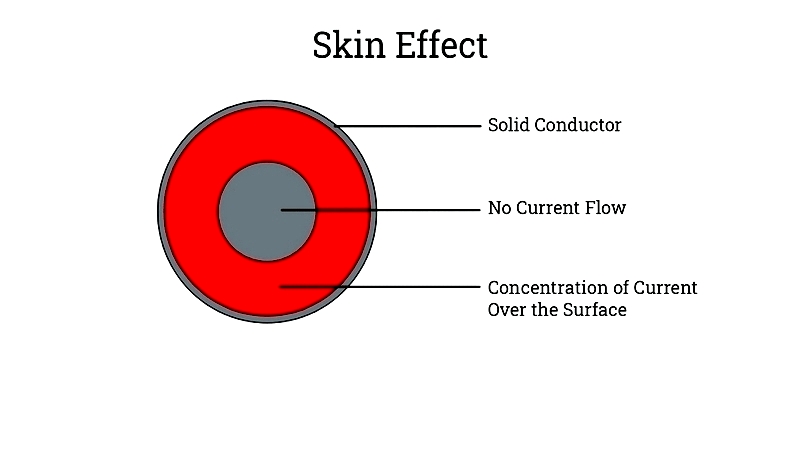

Reflection

Conductive materials like copper reflect EMI by generating opposing fields. Design considerations include minimizing gaps and addressing the skin effect in high-frequency applications.

Absorption

Magnetic materials like steel absorb EMI through hysteresis and eddy currents. This is particularly effective against low-frequency interference.

Multiple Reflections

Composite materials scatter EMI through internal structures, enhancing attenuation. This approach benefits compact devices where traditional shielding is impractical.

Effective shielding requires considering frequency, EMI type, and material properties. Innovations continue to advance shielding technologies for modern electronics.