Introduction

This section covers all available information about dust collection systems online.

You will learn about:

- Dust Collection System basics

- System operation principles

- Different system types

- System benefits

- Additional relevant information

Chapter One – Understanding Dust Collection Systems

These systems remove airborne particles in manufacturing plants and industrial settings by filtering air through specialized filters. The cleaned air is then either released outside or recirculated if it meets emission standards.

With increasing environmental concerns, these systems have become essential for dust-producing industries. Companies must comply with strict regulations from agencies like EPA, NFPA, and MSHA, demonstrating their systems' effectiveness.

Chapter Two – System Operation

While fundamentally designed to remove industrial contaminants, dust collection systems involve complex designs and advanced filtration technologies to ensure workplace safety and regulatory compliance.

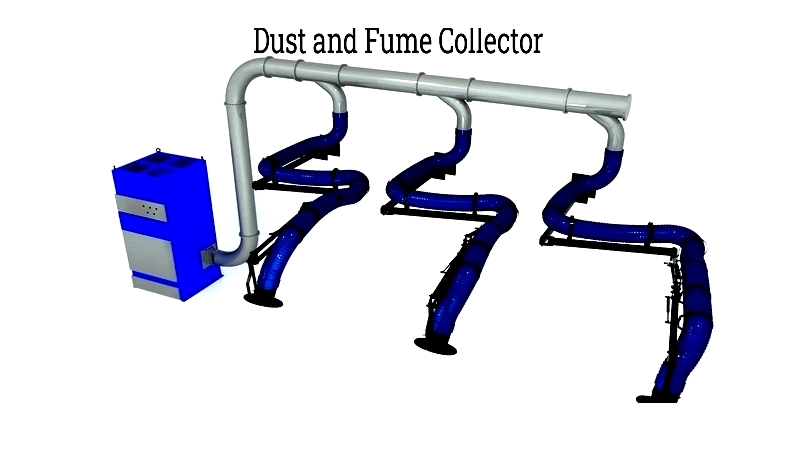

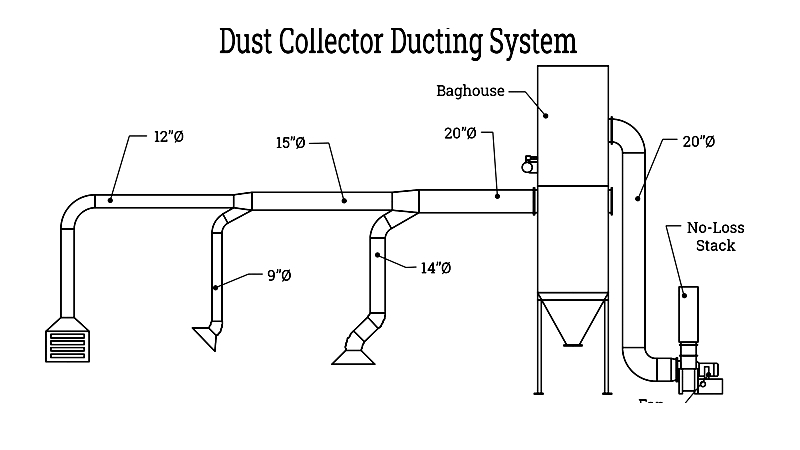

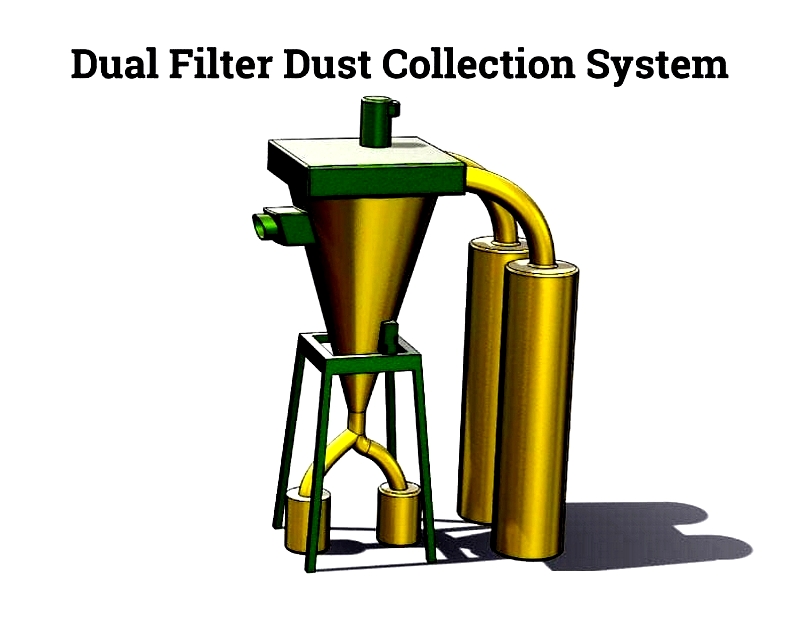

Effective systems typically include several key components: industrial fans, filtration media, cleaning mechanisms, collection containers, ductwork, and capture systems. Common industrial variants include baghouses, cyclones, cartridge collectors, wet scrubbers, and electrostatic precipitators, with baghouses being most prevalent due to their 99% efficiency rates.

These systems handle various particulates including metal shavings, wood dust, welding fumes, and pharmaceutical powders. Manufacturers customize solutions to meet specific industry requirements and safety standards.

System Functionality

Modern systems combine duct networks, filtration devices, and collection units. Selection depends on application needs, airflow rates, particulate types, and facility layout. important considerations include OSHA compliance, NFPA standards, and energy efficiency.

Ductwork Design

Proper ductwork planning ensures effective airflow and dust control. Design factors include equipment size, airflow requirements, pipe length, number of collection points, and particulate characteristics. Proper configuration prevents clogs and maintains system efficiency.

Air Movement Components

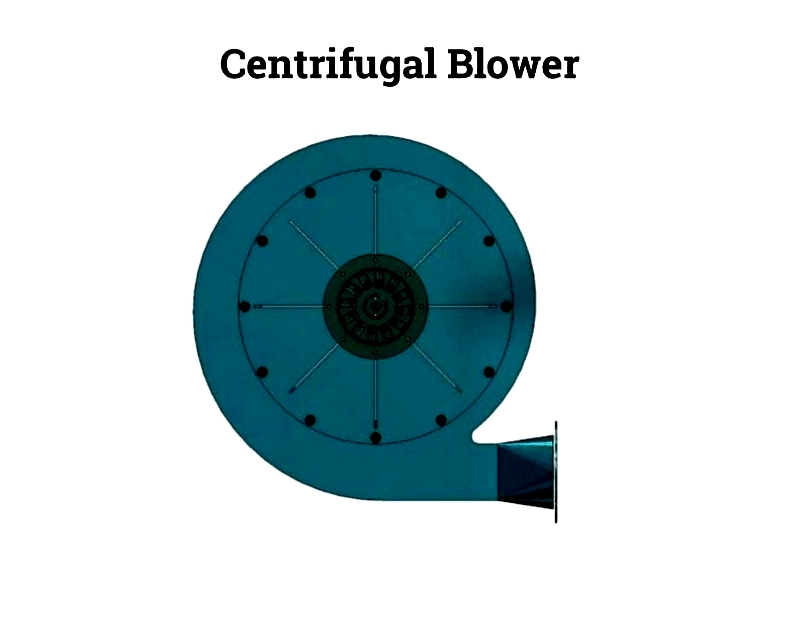

Fans and blowers are crucial for system operation, selected based on required air volume (CFM) and static pressure. Environmental factors like temperature and humidity also influence selection.

These components create suction to move contaminated air through the system. Centrifugal blowers handle high-pressure situations, while axial fans suit high airflow needs at lower pressures.

Filtration Components

The primary filtration device removes hazardous particles from air streams. Selection depends on media type, micron rating, and contaminant properties. The air-to-cloth ratio indicates filtration efficiency and media lifespan.

Cleaning Mechanisms

Automated cleaning systems maintain efficiency by removing accumulated particles. Common methods include pulse jet cleaning, where compressed air dislodges buildup while the system remains operational.

Control panels monitor pressure differentials and initiate cleaning when needed. Monitoring devices help maintain compliance and system reliability while reducing downtime.

Alarms alert operators to maintenance needs or system issues, ensuring continuous operation and air quality control.

Collection Components

Captured particles are stored in specialized containers for disposal or recycling. Design varies based on particulate characteristics and operational needs. Common options include:

- Sealed containers for safe particulate transfer

- Replaceable drums/bags for smaller operations

- Rotary valves preventing air leakage during disposal

- Screw conveyors for automated material movement

- Pneumatic systems for large-scale operations

Proper receptacle management ensures system efficiency and minimizes safety risks from accumulated dust.