Introduction

This article provides a comprehensive overview of baghouses.

You will explore key topics including:

- What is a Baghouse?

- Types of Baghouses

- Types of Baghouse Filters

- Baghouse Hopper Discharge Methods

- And more...

Chapter One - What is a Baghouse?

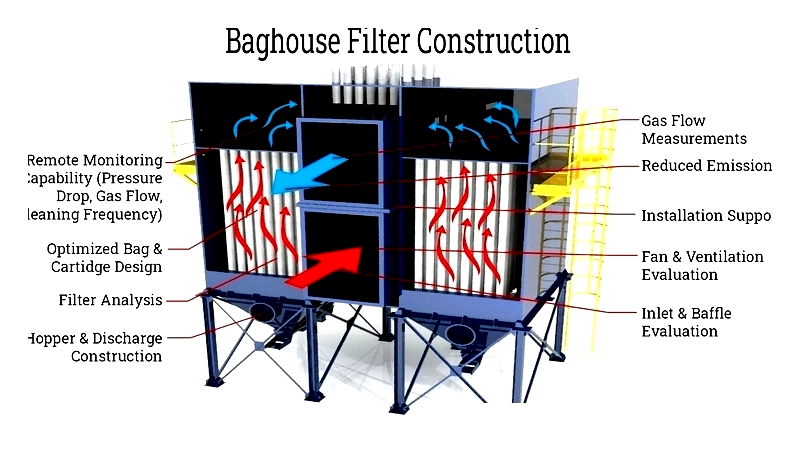

A baghouse is a dust collection system that uses tubes, cartridges, or envelopes to remove dust, particles, and debris from the air in manufacturing or processing facilities. Its key components include filter media or bags that capture particles as air passes through the system.

In a baghouse system, particles accumulate on filter surfaces as air flows through, forming a dust cake that may eventually restrict airflow. Regular filter cleaning is therefore necessary, typically performed using reverse air, shaking, or pulse jet methods.

Chapter Two - What are the Different Types of Baghouses?

Baghouses, or fabric filter dust collectors, are crucial industrial air filtration devices that improve air quality in manufacturing environments. They are classified by their cleaning technologies: shaker clean, reverse air, and pulse jet (also called mechanical cleaning, gas cleaning, and compressed air cleaning). Each method offers distinct benefits for specific industrial dust collection needs.

These systems use durable fabric filter bags made from materials like polyester or fiberglass to trap airborne contaminants. While excellent for dry dust collection, they're unsuitable for wet or sticky materials. For fine particulates, cartridge collectors may perform better, while cyclone dust collectors can protect filters from high-temperature or abrasive dust.

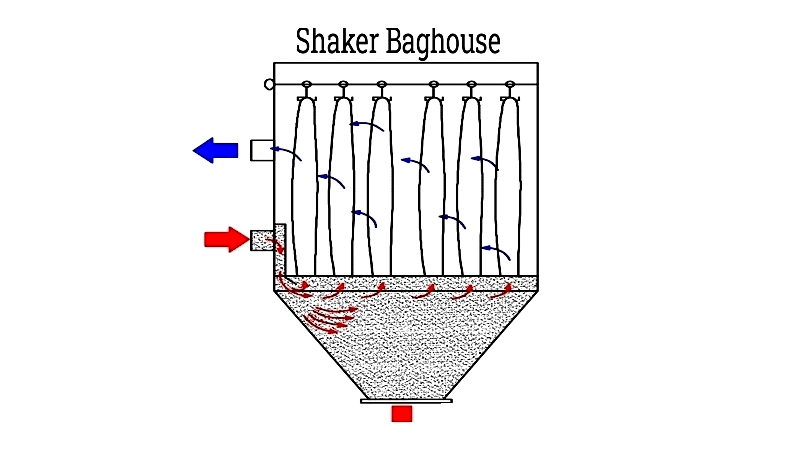

Shaker Baghouse

This type uses mechanical shaking to clean its filters. Air enters from the bottom, flows upward through suspended bags, with clean air exiting at the top. During cleaning, airflow stops and the bags are shaken to dislodge accumulated dust.

While simple, this method isn't the most efficient. The bags require frequent inspection and maintenance. Shaker baghouses work best for low-volume operations and dry, free-flowing dust applications where continuous operation isn't required.

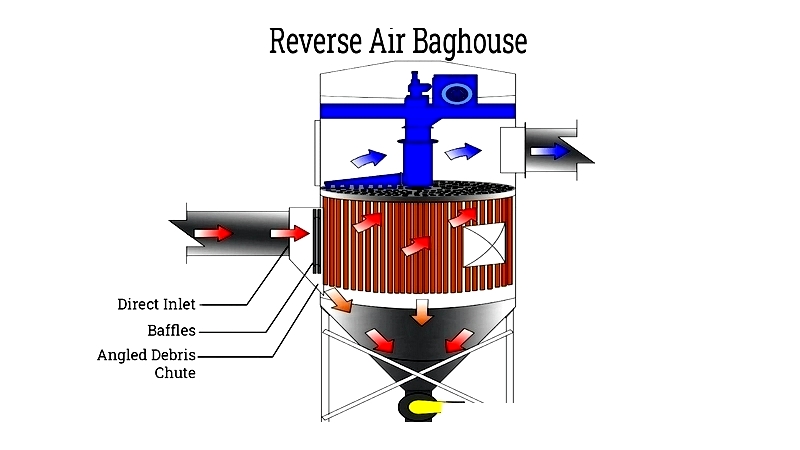

Reverse Air Baghouse (R/A)

In this design, bags are supported at top and bottom to withstand air pressure. Dust collects outside the bags, and cleaning uses low-pressure air from a rotating arm. Two main designs exist: round (continuous operation) and rectangular (compartmentalized cleaning).

Rectangular models use a reverse fan to slightly collapse reinforced bags during cleaning. These systems excel in power generation, cement, and steel industries where they handle large airflows and abrasive dust efficiently.

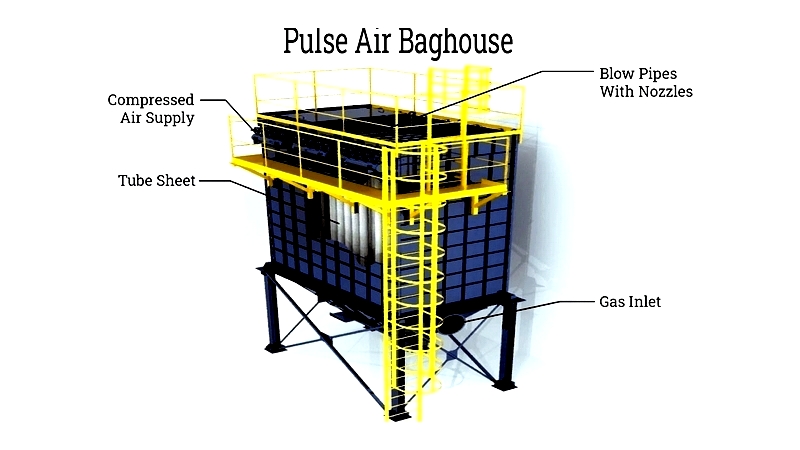

Pulse Jet Baghouse

This high-efficiency system uses compressed air bursts to clean bags while operating. Air enters below the bags and flows upward, with dust collecting externally. Cleaning involves rapid air pulses that create a rippling effect to dislodge particles.

Pulse jet baghouses are industry standards due to their low maintenance, continuous operation, and media versatility. They're widely used in food, chemical, and pharmaceutical industries to meet air quality regulations.

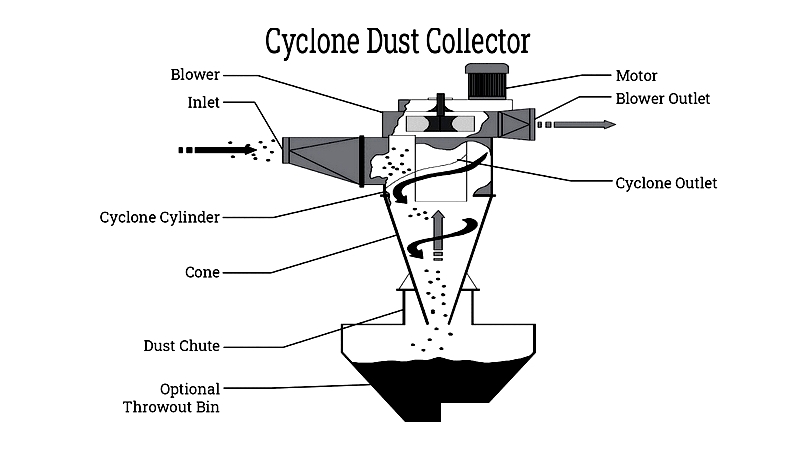

Cyclone Dust Collector

This pre-processing unit removes heavy particles before fine filtration. Air spins rapidly inside, forcing large particles outward where they fall into a collection container. Cyclones are commonly paired with baghouses in woodworking and minerals processing to improve overall system efficiency.

Variable Frequency Drive (VFD)

VFDs optimize baghouse performance by automatically adjusting fan speed to maintain proper airflow as filters load. This improves efficiency, reduces energy use, and minimizes component wear. VFD integration lowers operating costs, supports sustainability goals, and extends system lifespan while reducing manual adjustments.