Introduction

This section describes different types of ribbon mixers, their manufacturers, and the advantages they offer.

You will learn about:

- What a Ribbon Mixer is

- Various Ribbon Mixer types

- How Ribbon Mixers operate

- The advantages of using Ribbon Mixers

- And more...

Chapter 1: Understanding Ribbon Mixers

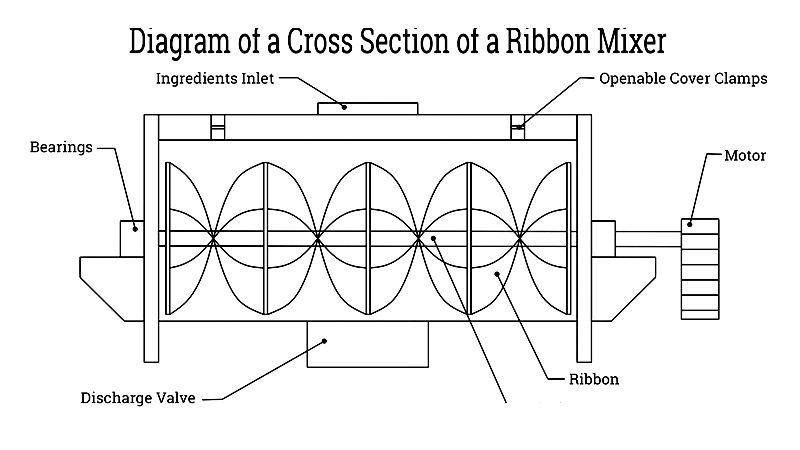

Ribbon mixers are specialized blending devices that use helical ribbons to mix materials effectively by moving them inward, outward, forward, and backward during operation. These mixers are particularly suitable for blending slurries, dry powders, and granular materials. Their design features a single shaft with spokes that hold helical ribbons, enabling efficient mixing. In dual ribbon mixers, external ribbons pull material from the sides toward the center while internal ribbons push it back outward, creating a thorough folding and mixing action.

A defining characteristic of ribbon mixers is their U-shaped drum that houses the helical ribbons. This U-shaped trough, also called a U-shaped horizontal trough mixer, distinguishes ribbon mixers from other industrial mixers. The U-shape offers practical benefits such as easy ingredient loading, simple cleaning, and highly effective mixing capabilities.

Image Provided by Charles Ross & Son Company

Image Provided by Charles Ross & Son CompanyThe unique U-shaped design allows for the addition of choppers and spray systems, which are useful for blending liquids, semi-solids, coatings, and low-viscosity pastes. Like all blenders, the ribbon mixer's core functionality comes from its trough or drum. This component is sealed, welded, and polished to maximize mixing efficiency.

Chapter 2: Types of Ribbon Blenders

Ribbon blenders, also known as ribbon mixers, are versatile industrial machines designed for uniform blending of powders, slurries, granules, and other bulk solids. These mixers are essential in industries such as food processing, pharmaceuticals, chemicals, cosmetics, and agriculture. Their primary function is to ensure consistent mixing—whether for dry powders, wet mixes, or coating dry materials with integrated spray systems. The helical ribbons' movement creates efficient shearing and kneading, guaranteeing uniform product quality. A key advantage of ribbon blenders is their durable yet accessible construction: the ribbons, mounted precisely on a central shaft, ensure thorough mixing, minimal residue, and easy maintenance for sanitary operation.

Ribbon blenders feature a specific gap between the mixing ribbons and trough walls, which is crucial for effective blending without dead zones. Some industrial applications include wipers to reduce material buildup on walls, further improving mixing efficiency. Power transmission systems vary, including chain drives, belt drives, and direct gearbox drives, each providing optimal torque and longevity for different processing needs. Choosing the right ribbon blender and drive system is essential for batch consistency, energy efficiency, and high-quality powder or granule mixing.

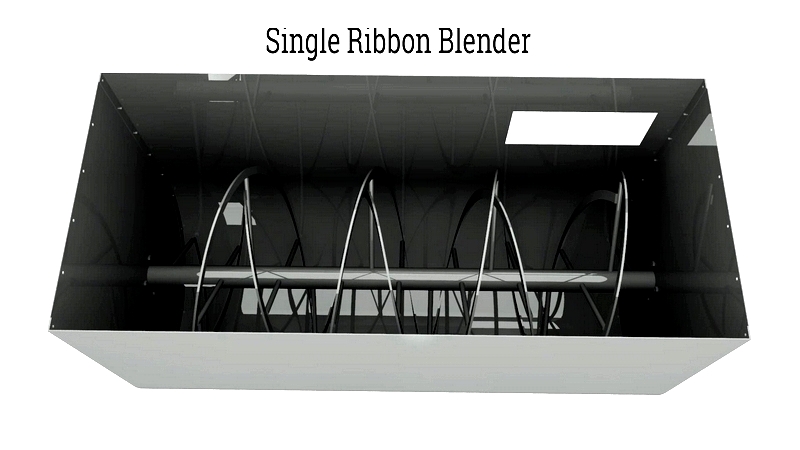

Single Ribbon Blenders

Single ribbon blenders, or single shaft ribbon mixers, have one helical ribbon agitator and are ideal for materials that don't require intensive mixing. Commonly used in food flavorings, animal feed, and simple granule blending, they provide gentle mixing with minimal risk of over-shearing. Their simple design has fewer moving parts, reducing maintenance costs and simplifying operation. Single ribbon blenders come in vertical and horizontal configurations. Vertical models resemble traditional upright mixers with top loading, while horizontal versions are designed for continuous feeding and effective radial and axial material movement for uniform blending. These blenders are often preferred in nutraceuticals and plastics compounding for their simplicity and reliability.

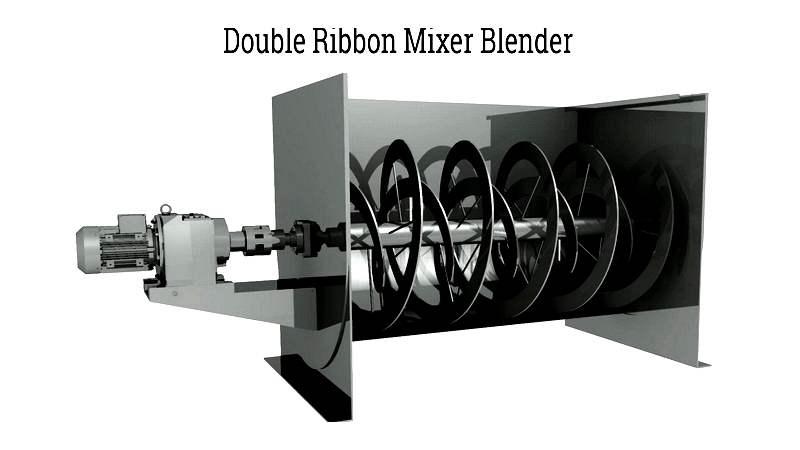

Double Ribbon Blender

Double ribbon mixers, or dual ribbon blenders, are widely used in food, chemicals, and pharmaceuticals for blending diverse ingredients. They feature two offset helical ribbons—a larger outer ribbon and a smaller inner ribbon—on the same shaft, creating a highly efficient counter-current mixing action. The inner ribbon pushes material in one direction while the outer ribbon moves it oppositely, resulting in rapid, high-shear mixing with exceptional uniformity. This design is ideal for demanding recipes like spice mixes, baking ingredients, and chemical additives where precise mixing and batch consistency are critical.

Double ribbon blenders offer various discharge options (center bottom or end discharge) to suit material viscosity and flow characteristics. Optimal mixing times typically range from five to twenty minutes, depending on batch size and complexity. These blenders are energy-efficient, achieving thorough mixing with lower power consumption due to the vortex mixing effect created by the dual ribbons. Engineers often choose double ribbon mixers for their versatility, scalability, and proven performance in both pilot-scale and large-scale production.

The forward and reverse rotation of a double ribbon mixer along the same horizontal axis creates a low-power, efficient vortex mixing process that speeds up and improves mixture homogeneity.

Triple Ribbon Blenders

Triple ribbon blenders are specialized mixers with three sets of mixing ribbons—one central and two side ribbons—for aggressive and efficient mixing. This advanced design achieves unparalleled blend uniformity in less time. The ribbon configuration is engineered to eliminate dead spots and ensure quick, complete discharge, making these blenders ideal for complex formulations like specialty chemicals, mineral blends, and nutraceuticals.

As the central agitator rotates, ingredients move along the trough interior. The opposing pitch of the inner and outer ribbons systematically moves product back and forth, ensuring thorough mixing. This continuous motion accelerates homogenization and reduces production downtime. Triple ribbon blenders are often selected for high-stakes industrial settings where batch-to-batch consistency and product quality are paramount.

Ribbon Paddle Mixer Blender

Ribbon paddle mixer blenders are hybrid industrial mixers that combine paddle tumbling with ribbon rolling for superior mixing flexibility. This dual mechanism creates a double reversing effect, ideal for materials with varying particle sizes, densities, or moisture content. The agitator design can be customized—ribbons inside with paddles outside, or vice versa—to optimize shear and agitation for different products.

Hybrid agitators function similarly to standard ribbon mixer blades: paddles or outer ribbons move ingredients toward the discharge port while inner components push material away. This is especially useful for sticky substances, pastes, or soft agglomerates like bakery dough, ready-made meals, or personal care powders. Ribbon paddle blenders are preferred by contract manufacturers, R&D labs, and pilot plants working with both free-flowing and cohesive materials.

Vertical Ribbon Mixers

Vertical ribbon mixers feature an upside-down cone or cylindrical shape with a vertical spiral ribbon agitator. This design creates upward and downward material movement—perimeter ingredients are lifted while center materials flow down—ensuring uniform mixing even with difficult-to-blend powders or fragile components. The moderate-speed rotation makes these mixers suitable for heat-sensitive or shear-sensitive materials like pharmaceuticals, fine chemicals, and specialty food ingredients.

With space-saving designs and simplified drive mechanisms, vertical ribbon mixers fit well in facilities with limited space. The gentle, gravity-assisted mixing prevents ingredient breakage and eliminates dead zones. A key advantage is their adaptability to small batch sizes—as low as 10% of total capacity—making them ideal for artisan producers, craft operations, and test labs with variable production runs.