Introduction

This article provides an in-depth exploration of curing ovens and their applications.

You will gain insights into various topics including:

- How Curing Ovens Function

- The Manufacturing Process of Curing Ovens

- Different Types of Industrial Curing Ovens

- Practical Applications of Curing Ovens

- Advantages of Using Curing Ovens

- Maintenance and Operational Considerations

- Additional Relevant Information

Chapter 1: Understanding Curing Oven Functionality

This chapter examines the operational principles of curing ovens and the heat treatment techniques they employ.

What is a Curing Oven?

A curing oven is specialized thermal equipment used to improve material strength and durability. These industrial ovens are essential for manufacturing processes like baking, drying, and curing, where controlled heating triggers specific chemical reactions. Below is an illustration of a typical curing oven.

How Heat Treating Ovens Work

As heat treating equipment, curing ovens elevate material temperatures to specific thresholds, enhancing physical-chemical bonds and mechanical properties. Catalysts are often used to accelerate reactions and produce more resilient products.

The importance of Catalysts

Catalysts significantly reduce processing time in curing ovens by accelerating chemical reactions. Different catalysts are effective at specific temperature ranges, with Isocyanate groups being commonly used.

Principles of Air Circulation

Curing oven operation depends on two fundamental aspects:

- Heat sources

- Airflow patterns

Primary Heat Sources

Curing ovens utilize various heat sources including electricity, gas (direct/indirect), steam, ultraviolet light, oil, and hot water, which also determine oven classifications.

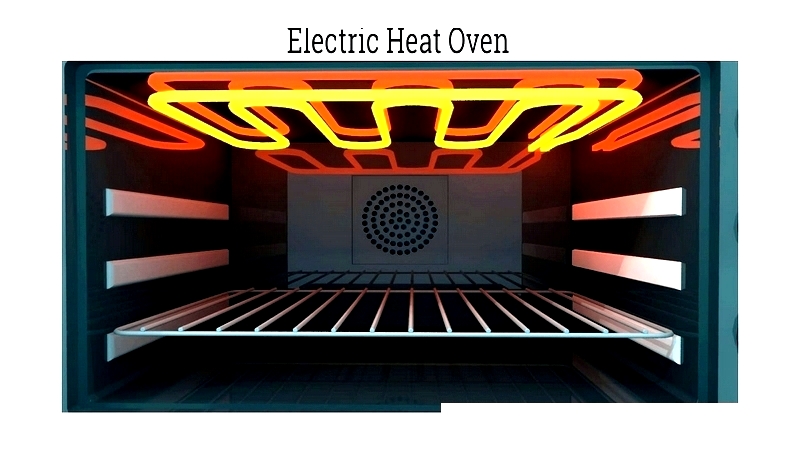

Electric Heat Ovens

Electric ovens use electrical elements for heating, offering rapid temperature control, cost-effectiveness, and precise operation. They are ideal for combustible materials like aluminum.

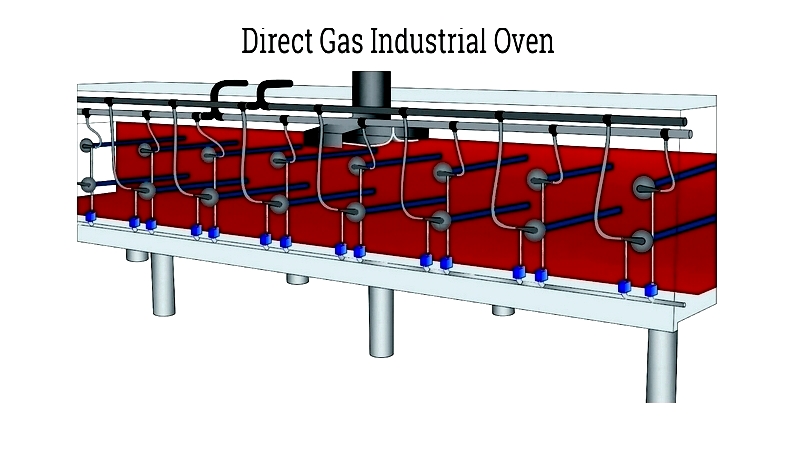

Direct Gas Ovens

These ovens apply direct flame heating, which risks damaging delicate materials. While maintenance is simpler than electric models, they require complex systems and are more expensive initially.

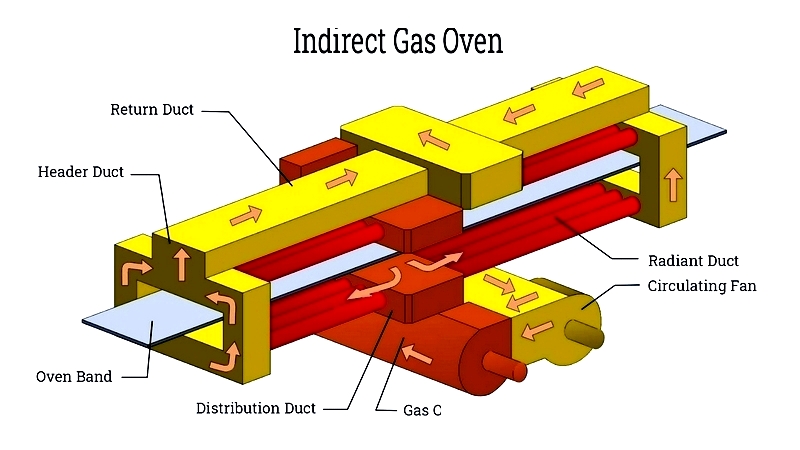

Indirect Gas Ovens

Heat is transferred through stainless steel exchangers, protecting materials from direct flame exposure. Though more complex to maintain, they provide superior results for sensitive applications.

Steam Ovens

Environmentally friendly and cost-effective, steam ovens achieve high temperatures but are unsuitable for rust-prone materials and have longer heat-up times.

Hot Water Ovens

Using radiator coils, these ovens provide clean heating but are limited to temperatures below 70°C.

Oil-Fired Ovens

Primarily used as backup systems, these ovens are less common due to high costs and operational complexity.

Airflow Optimization

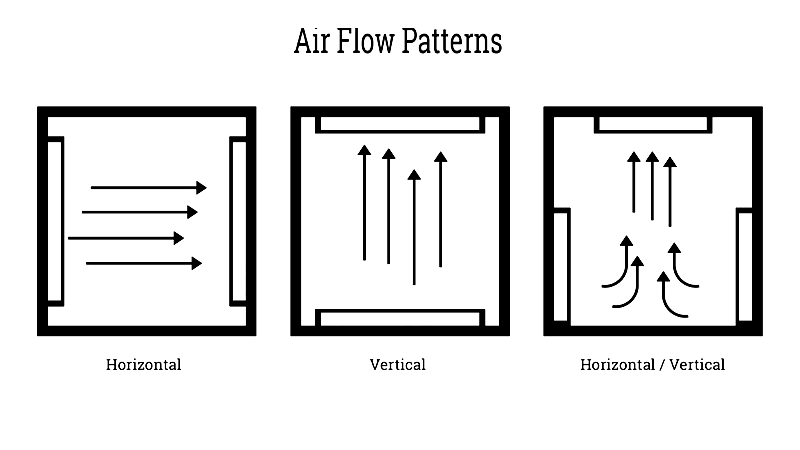

Proper airflow ensures even heat distribution and prevents material damage. Common patterns include:

Vertical/Horizontal Flow

Effective for large parts, with air entering through sidewalls and exiting via the ceiling.

Full Horizontal Flow

Ideal for shelved or suspended small parts, circulating air horizontally across shelves.

Vertical Flow

Best for small hung components, with air moving vertically from bottom to top.

Chapter 2: Curing Oven Construction

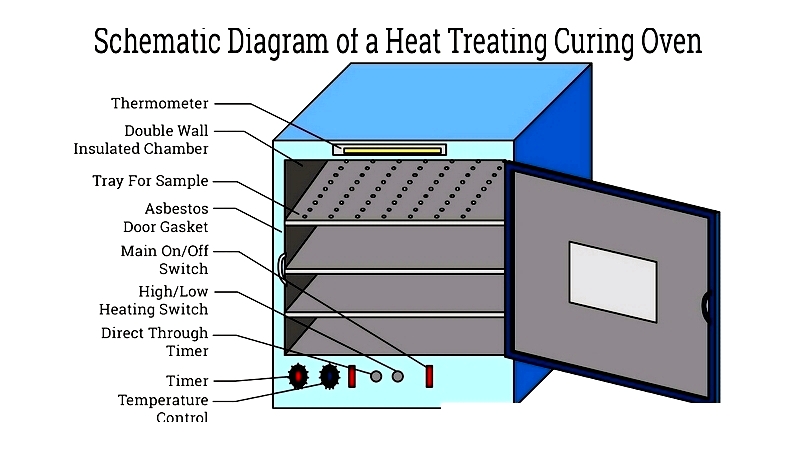

Industrial curing ovens are engineered for uniform heat distribution and consistent results in applications like powder coating and metal finishing. Key components include:

- Oven enclosure

- Heating system

- Air supply

- Air recirculation

- Exhaust system

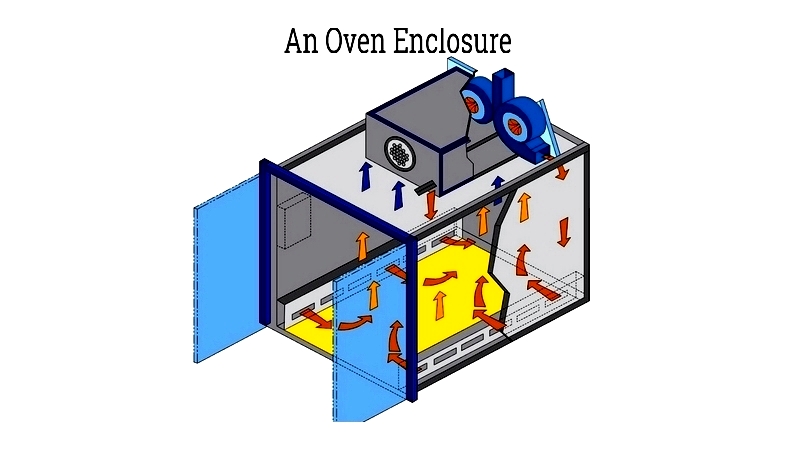

The Oven Enclosure

This insulated chamber maintains precise temperature control and safety. Design considerations impact efficiency and quality, with essential features including:

- Electrical Systems: Motors, switches, and power supplies for automation and safety.

- Fuel Systems: Critical for gas-fired ovens, ensuring safe heat generation.

- Safety Mechanisms: Explosion relief systems for volatile material processing.

- Mechanical Components: Conveyors and handling systems for efficient operation.

- Heat Recovery: Energy-saving solutions to reduce operational costs.

- Thermal Components: Insulation and heat exchangers for temperature control.

- Control Systems: Precision instrumentation for process regulation.

- Automation: PLC and IoT systems for advanced process management.

The illustration shows a typical enclosure with numbered components:

- Structural steel framework

- Double-door system with safety seals

- Compliance markings

- Electronic control unit

- Explosion relief system

- Heating chamber

- Exhaust fan

- Circulation fans

- Temperature uniformity

- Ductwork

- Volume control dampers

- Distribution dampers

- Insulated panels

The Heating System

The core component ensuring consistent heat generation, with considerations for:

- Construction: Durable materials and filtration for clean operation.

- Air Supply: Optimized ductwork for uniform heat distribution.

Modern systems incorporate smart controls for efficiency and maintenance optimization.

Air Recirculation

This energy-saving system recycles heated air while maintaining process stability. Proper design prevents temperature variations that could affect product quality.