Introduction

This section provides descriptions of gas analyzers and monitors, lists manufacturers, and explains different types of gas detection equipment.

You will learn about:

- Gas detector fundamentals

- Various gas detector types

- Practical applications

- Operating principles

- Additional relevant information

Chapter 1: Understanding Gas Detectors

Gas detectors are specialized instruments that measure gas concentrations. These devices utilize various sensor technologies including combustible sensors, infrared point sensors, ultrasonic sensors, photoionization detectors, MOS sensors, and electrochemical sensors. Each sensor type detects specific gases, providing measurable data for documentation and analysis.

The equipment primarily detects combustible and toxic gases. Beyond the sensor, a typical gas detector includes a control unit and alarm system. The sensor measures gas levels while the control unit manages monitoring operations and triggers alerts when necessary.

Chapter 2: Types of Gas Detectors

Gas detectors serve critical roles in industrial safety and environmental monitoring by identifying hazardous gases. Available in multiple configurations, each type is designed for specific gas detection applications across various industries including oil and gas, chemical production, mining, and manufacturing. Understanding detector technologies is essential for proper device selection to meet safety and regulatory requirements. Gas detectors are generally classified into two main categories: portable and fixed systems. Portable detectors are handheld devices for personal safety during inspections. Fixed detectors provide continuous area monitoring as part of comprehensive safety systems.

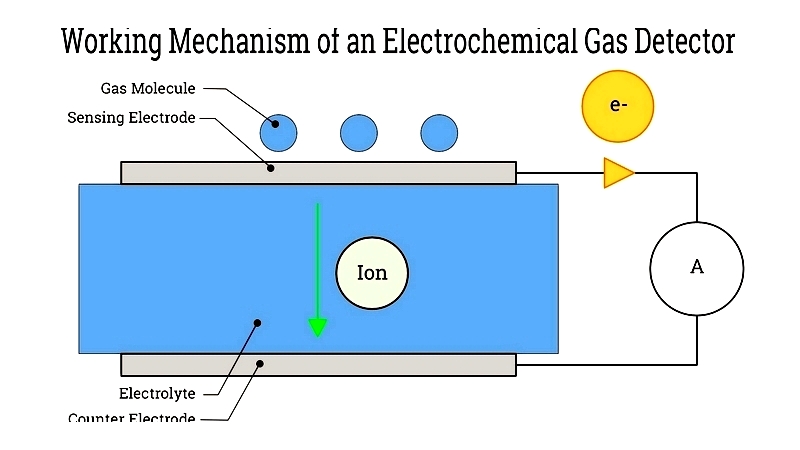

Electrochemical Gas Detector

These sensors detect toxic gases like CO, H2S, Cl2, and NH3 through electrochemical reactions. The amperometric principle measures current proportional to gas concentration. Environmental gases diffuse to the sensor while the electrolyte remains protected. Reaction at the working electrode generates a measurable signal that the device processes into concentration readings. These sensors offer high sensitivity and low power consumption, making them suitable for various applications.

Potential cross-sensitivity requires selective filters and proper calibration for accurate performance in industrial settings.

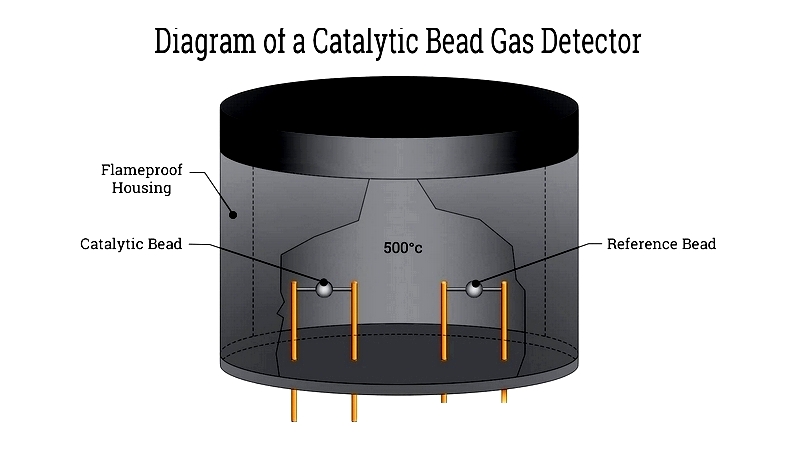

Catalytic Bead Gas Detector

Commonly called Pellistor sensors, these detect flammable gases like methane and propane. The design features catalytic and reference beads in a Wheatstone bridge circuit. Combustible gas reacts on the catalytic bead, changing resistance that indicates gas concentration as a percentage of LEL. These detectors provide fast response for explosion protection in hazardous areas.

While effective, they can be affected by catalyst poisons and require adequate oxygen.

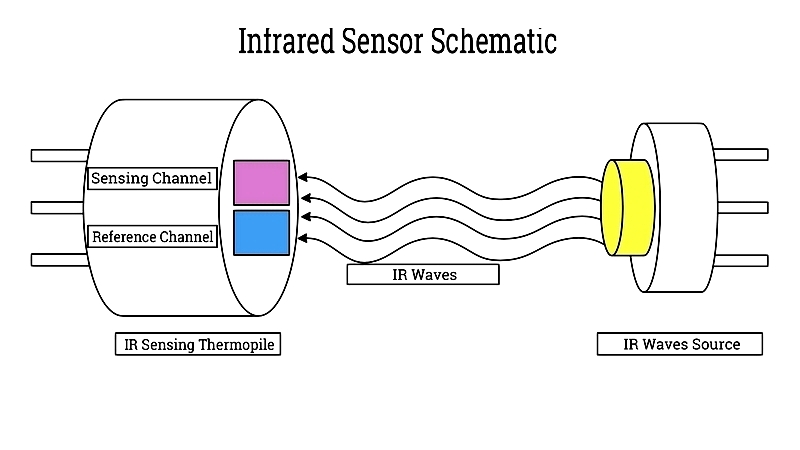

Infrared Gas Detectors

IR detectors measure hydrocarbon gases and CO2 using optical technology. The system includes an IR source, filter, and receiver that detects gas-specific wavelength absorption. Available as point or open-path detectors, they operate effectively in oxygen-deficient environments with minimal calibration needs.

These detectors resist false alarms and provide reliable monitoring for industrial facilities.

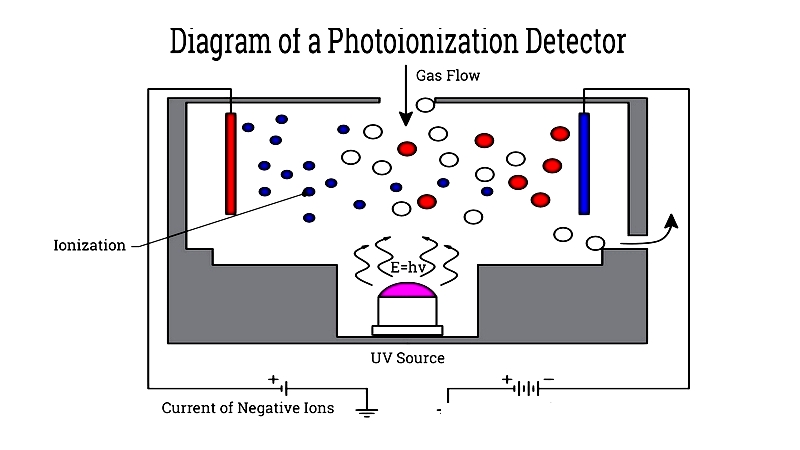

Photoionization Gas Detector (PID)

PIDs detect VOCs using UV light to ionize gas molecules, producing measurable current. Ideal for industrial hygiene and environmental monitoring, they require regular calibration for accuracy. While sensitive to many compounds, they cannot distinguish between specific chemicals.

Widely used in hazardous materials response and air quality assessments.

Ultrasonic Gas Detector

These detectors identify leaks by monitoring ultrasonic sound waves from pressurized gas releases. Effective in ventilated areas, they enable early leak detection without requiring gas contact with the sensor.

Valuable for pipeline monitoring and preventive maintenance programs.

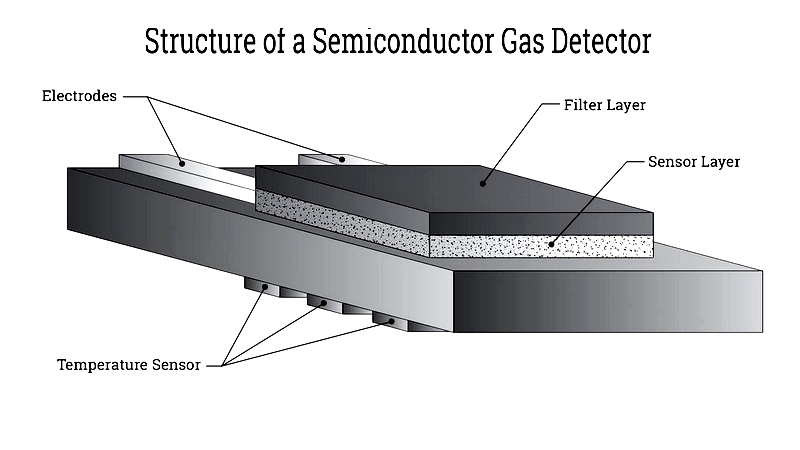

Semiconductor Gas Detector

Using gas-sensitive resistive films, these affordable sensors detect various gases through resistance changes. Common in residential alarms and automotive applications, they offer fast response but may be affected by environmental factors.

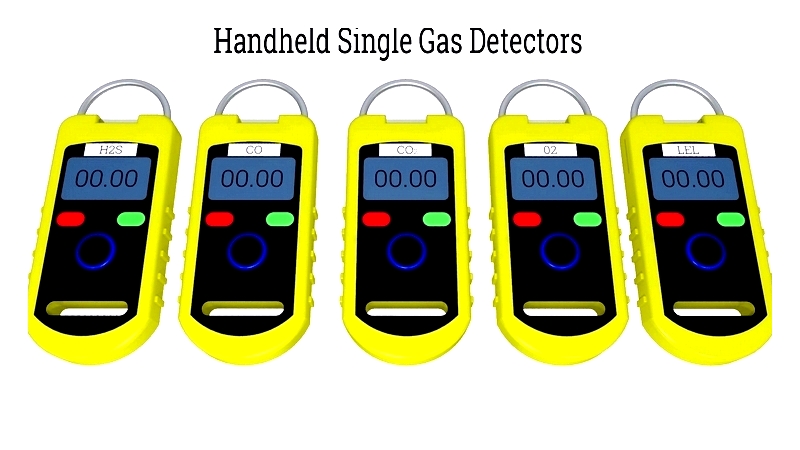

Single Gas Detectors

Dedicated to monitoring one specific gas, these compact devices are ideal for personal protection in confined spaces. With typical lifespans of 2-3 years, they feature simple operation and maintenance reminders.

Used across various industries for targeted gas monitoring.

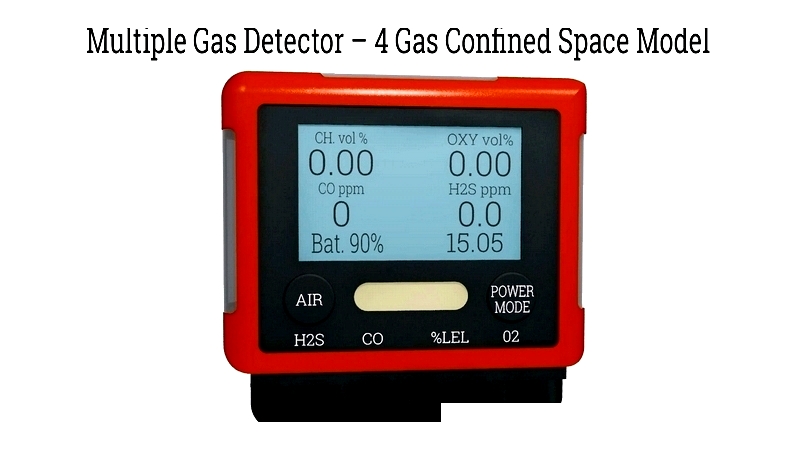

Multiple Gas Detectors

These advanced devices simultaneously measure several gases and oxygen levels. Configurable for specific needs, they feature alarms, data logging, and connectivity options. Essential for confined space entry and industrial safety applications.

Fixed and Portable Gas Detectors

Fixed systems provide continuous area monitoring with central integration, while portable detectors offer mobile protection for personnel. Selection depends on application requirements and safety standards.

Chapter 3: Explosion-Proof Gas Detectors

Designed for hazardous environments, these detectors feature rugged construction to contain potential ignitions. They meet strict safety standards like ATEX for operation in explosive atmospheres.

ATEX certification ensures suitability for zones with combustible materials. Proper detector selection is critical for gas leak detection in high-risk areas.

ATEX zones classify risk levels:

- Zone 0: Continuous gas presence

- Zone 1: Intermittent gas presence

- Zone 2: Rare gas presence

- Zones 10-22: Dust hazard areas

National Electrical Code Location

Classification system for hazardous areas:

- Class I: Flammable gases/vapors

- Class II: Combustible dust

- Class III: Ignitable fibers