Introduction

This article provides essential details about Glass Cutting.

You will learn about various topics including:

- What is Glass Cutting?

- Glass Cutting tools

- Glass Cutting process

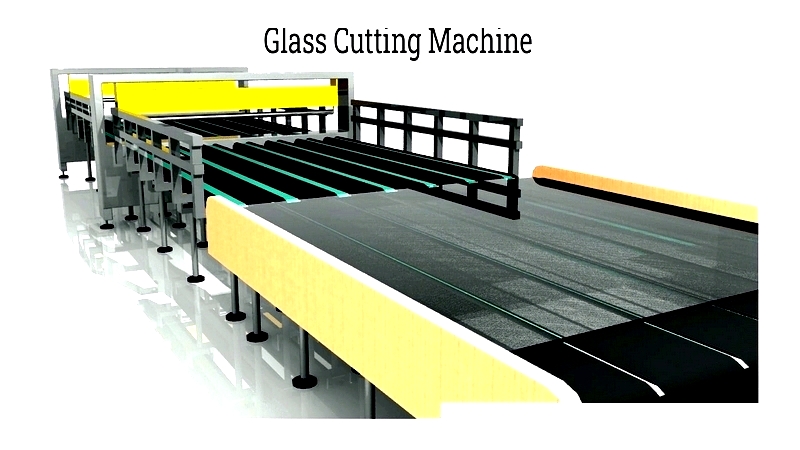

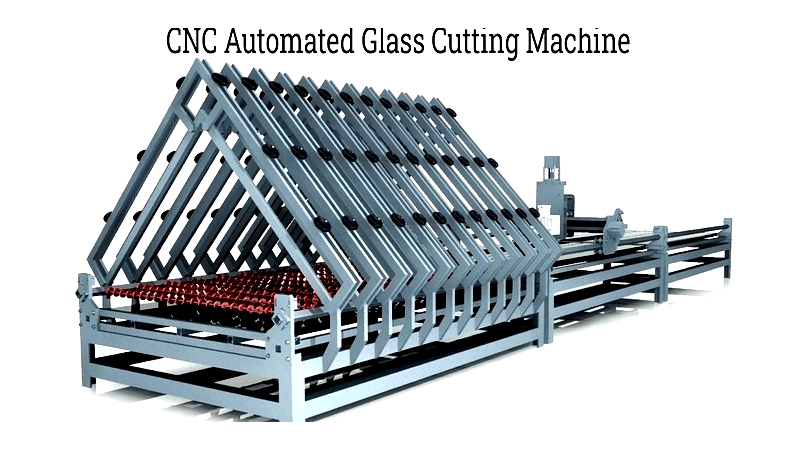

- Glass Cutting machines

- And more…

Chapter One - What is Glass Cutting?

"Glass fabrication" refers to various techniques used to transform raw glass into functional items or components, including cutting, grinding, drilling, polishing, tempering, finishing, and edging.

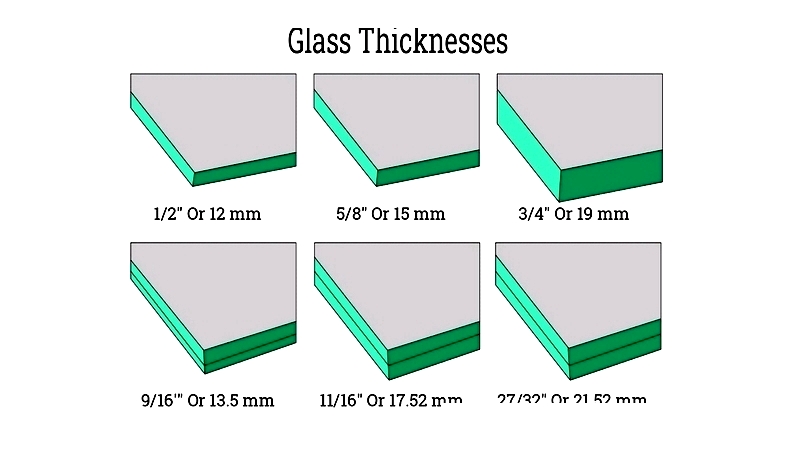

Glass cutting involves scoring a specific line on the glass to weaken its structure, allowing a clean break when pressure is applied. This method divides the glass along the scored line. Whether for industrial applications or DIY projects, the basic principles of glass cutting remain similar, with variations mainly due to glass size and thickness.

The key aspect of glass cutting is the scoring process, which creates a weak line in the glass. This line enables precise and controlled separation. After separation, the edges can be sanded, shaped, and smoothed for the desired finish.

Chapter Two - What are the different types of glass cutting tools?

Precision-engineered glass cutting tools are essential in the glass fabrication industry, helping professionals and hobbyists create accurate score lines for clean, controlled breaks. Whether working with window glass, stained glass, mirrors, or specialty glass, choosing the right tool simplifies the process while improving efficiency and safety.

Today's market offers a wide range of glass cutting tools, from simple handheld cutters to high-performance electric cutters and specialized saws like band saws and wet saws. Each type is designed for accuracy, minimal chipping, and user safety. Many tools also include features to maintain a clean work environment.

With various styles and technologies available, users can select tools tailored to their applications, experience level, and glass types. While all tools achieve scoring, the choice affects edge quality, precision, and ease of use.

Glass Cutting Tools

Handheld Glass Cutter

The handheld glass cutter is the most basic and widely used tool, valued for its precision and versatility in professional and home projects. Designed for comfort and control, it works well on flat glass types like float glass, plate glass, and stained glass.

Ergonomics is crucial when selecting a handheld cutter. A well-designed tool reduces strain and improves efficiency during extended use.

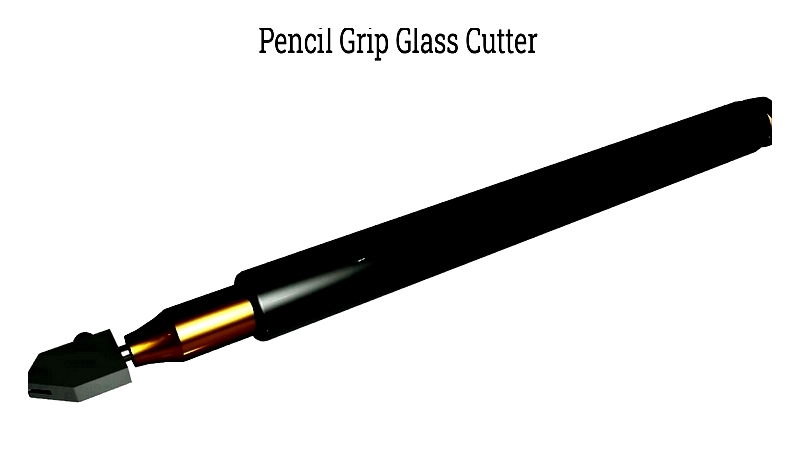

Pencil Grip

A pencil grip cutter features a slim, pencil-like shaft for precise control, favored by stained glass enthusiasts and glaziers. Many include an oil reservoir for lubrication, enhancing accuracy and wheel longevity.

Custom Grip

Custom grip cutters offer enhanced comfort with features like oil-filled handles and adjustable settings. These reduce fatigue and improve durability, making them ideal for large or thick glass pieces.

Thomas Grip

The Thomas grip cutter is compact and ergonomic, with a swivel head for detailed cuts. It suits stained glass artists and those needing exceptional control.

Fletcher Glass Cutter

The Fletcher cutter is a professional favorite for glass replacement and glazing work. Its slender design excels in straight and freehand scoring, though it may require frequent wheel replacement.

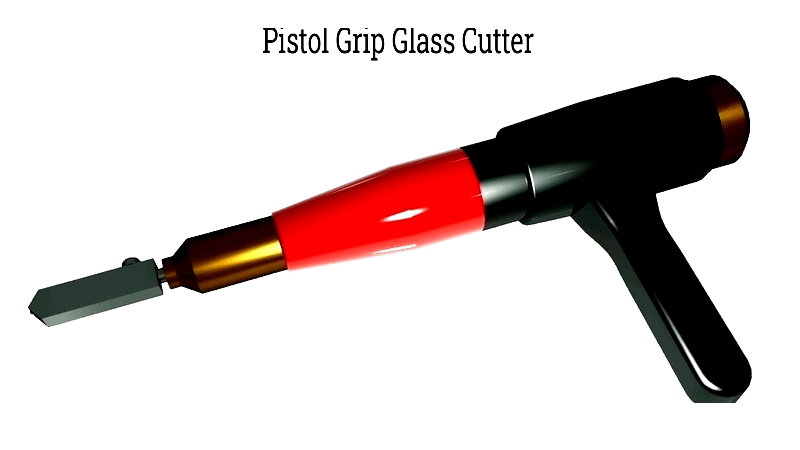

Pistol Grip

The pistol grip cutter offers improved leverage and comfort, ideal for thicker or larger glass panes. Its vertical pressure application eases scoring, making it popular among glaziers.

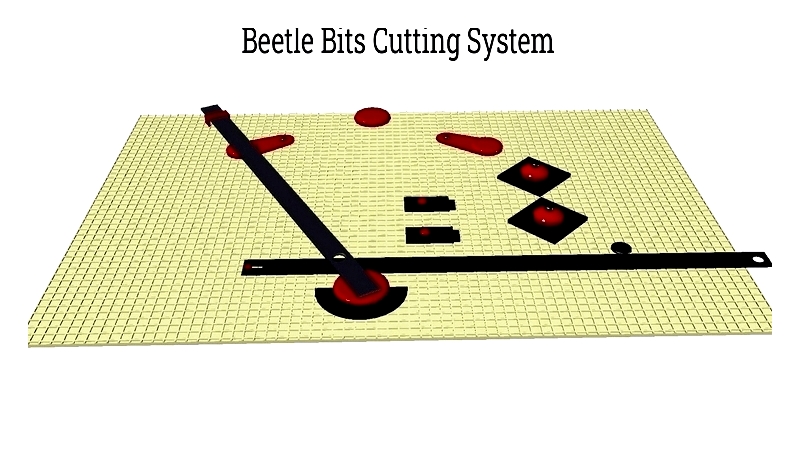

Beetle Bits Cutting System

The Beetle Bits system is a comprehensive kit for precise angles and patterns. Its adjustable features suit both professional shops and home studios, with an expandable cutting surface for larger projects.

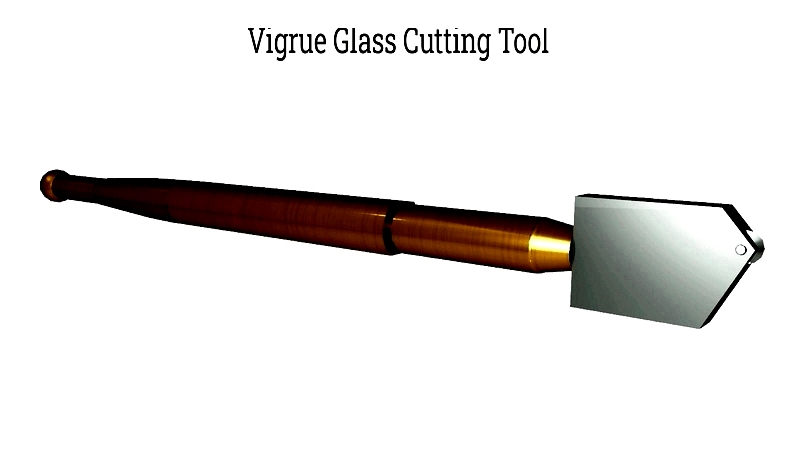

Vigrue Glass Cutter

The Vigrue cutter excels in cutting curves and circles with its swiveling head. It handles thick or tempered glass and mirrors, suitable for both DIY and commercial use.

Cutting Wheel

The cutting wheel is the core of any glass cutter, delivering precise score lines. Tungsten carbide wheels are preferred for their durability and sharpness, ideal for high-volume operations.

Glass Cutting Tool Considerations

When selecting a glass cutting tool, consider your project needs, experience level, and glass type. Below are key factors to evaluate.

Budget

Prices vary from under $20 for basic cutters to over $300 for advanced machines. High-quality tools reduce waste and improve precision.

Size

Choose tools based on glass size and thickness. Larger sheets may require long-arm cutters, while small projects suit compact handheld tools.

Types of Glass

Standard cutters work for float and annealed glass, but specialized tools are needed for tempered or laminated glass. Always check compatibility.

Tool Cutting Range

Select tools designed for your glass thickness. Light-duty cutters handle thin sheets, while heavy-duty tools suit thicker plates.

Oil

Cutting oil reduces friction and extends wheel life. Some tools include oil reservoirs for convenience.

Ergonomics

Comfortable tools improve control and reduce fatigue. Choose designs that suit your hand size and motion for better results.