Introduction

This article provides an in-depth exploration of inductors and inductor coils.

It covers essential topics including:

- The fundamentals of inductors and their basic principles

- Different types of inductors and inductor coils

- Core design considerations for inductor coils

- Practical applications of inductor coils

- Factors influencing inductance in inductor coils

- Key selection criteria for inductor coils

- And more...

Chapter 1: Understanding Inductors and Their Fundamental Principles

Inductors are passive electrical components with two terminals that store energy in magnetic fields. These components, commonly called coils or chokes, resist sudden current changes and are denoted by the symbol L in circuit diagrams. They serve vital functions in numerous electrical applications.

What Is an Inductor Coil?

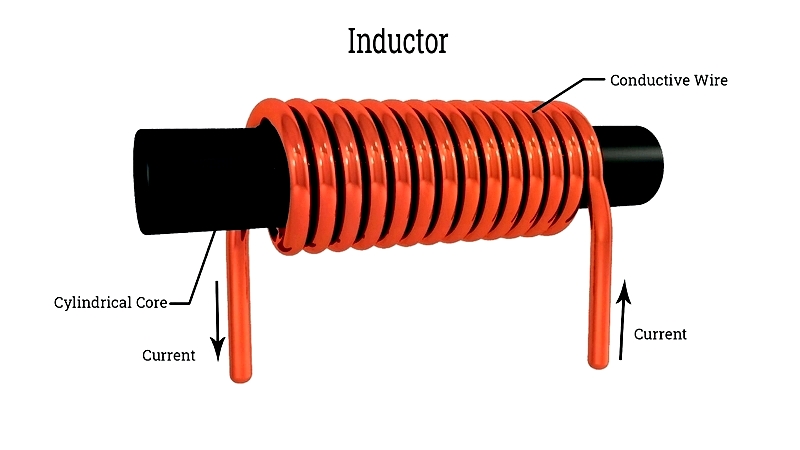

An inductor coil consists of conductive wire wound into a spiral shape, enabling current flow while generating a magnetic field.

Core Principles of Inductor Coils

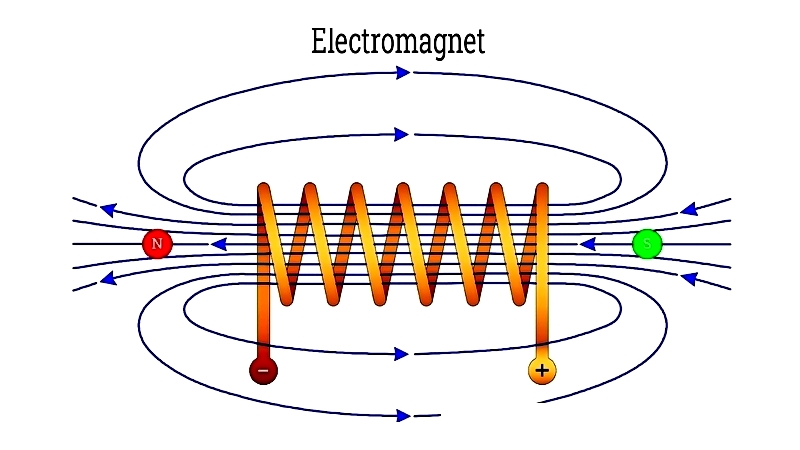

When current flows through a conductor, it creates a magnetic field following the right-hand rule. Coiling the conductor amplifies this effect, transforming the inductor into an electromagnet. Conversely, changing magnetic fields can induce electrical currents.

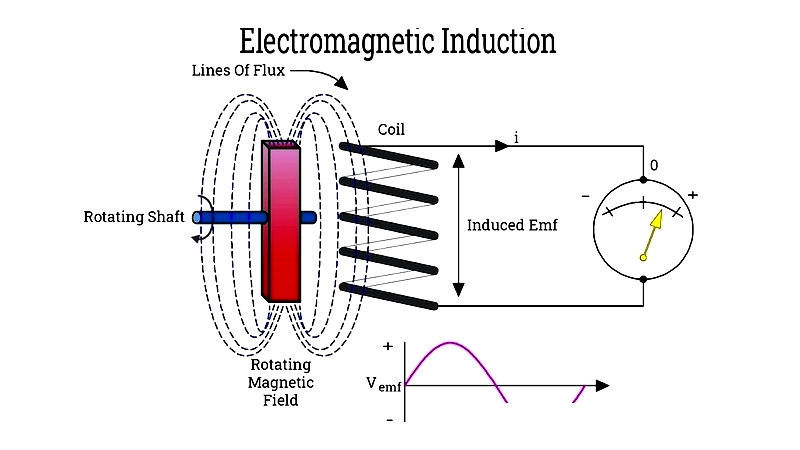

once magnetized, moving a magnet near the inductor alters its magnetic field, inducing a counteracting current. This electromagnetic induction phenomenon is shown in the diagram below. With DC current, the inductor immediately generates an opposing electromotive force.

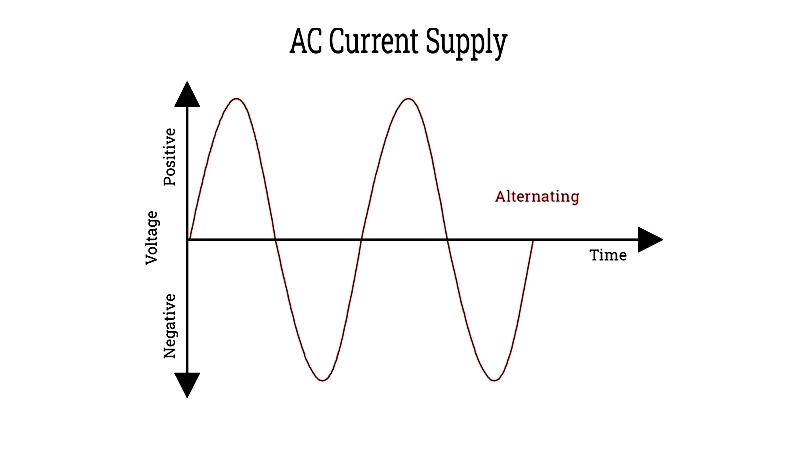

This self-induction effect diminishes as DC current stabilizes, allowing unimpeded flow. The electromotive force depends on the current's rate of change (ΔI/Δt). For AC current (shown below), voltage spikes initially due to rapid current changes.

As current change slows, voltage decreases, reaching zero at peak current. During current decline, negative voltage appears. The electromotive force creates a ¼ cycle phase shift between voltage and current waveforms. Consequently, inductors oppose AC current more than DC current. At high frequencies, this opposition becomes strong enough to block current flow entirely.