Introduction

This section covers descriptions of perforated plastic sheets, lists manufacturers, and explores their various applications.

You will learn about:

- The definition of perforated plastic sheets

- Manufacturing processes for perforated plastic sheets

- Common applications of perforated plastic sheets

- Different types of perforated plastic sheets

- Additional relevant information

Chapter 1: Understanding Perforated Plastic Sheets

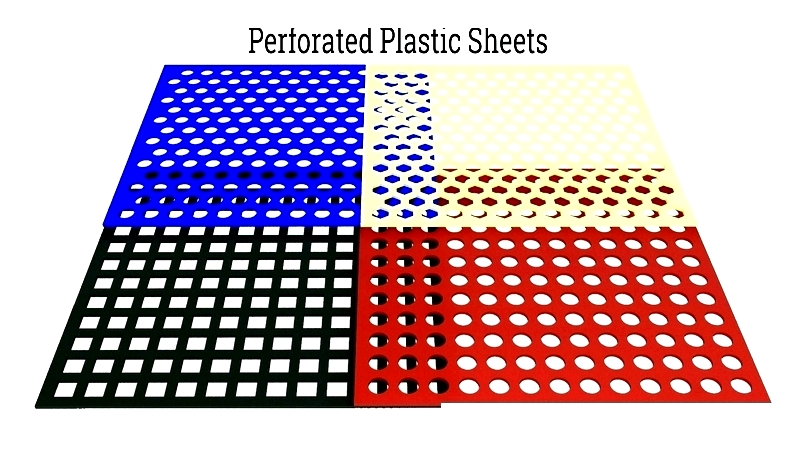

Perforated plastic sheets are plastic materials of varying thicknesses that feature holes in different shapes and sizes. These materials demonstrate resistance to heat, impact, and chemicals while remaining lightweight and easy to install. Their corrosion resistance and light weight make them suitable for diverse applications. Beyond improving aesthetics, perforated plastic helps control airflow, light distribution, visibility, and noise reduction.

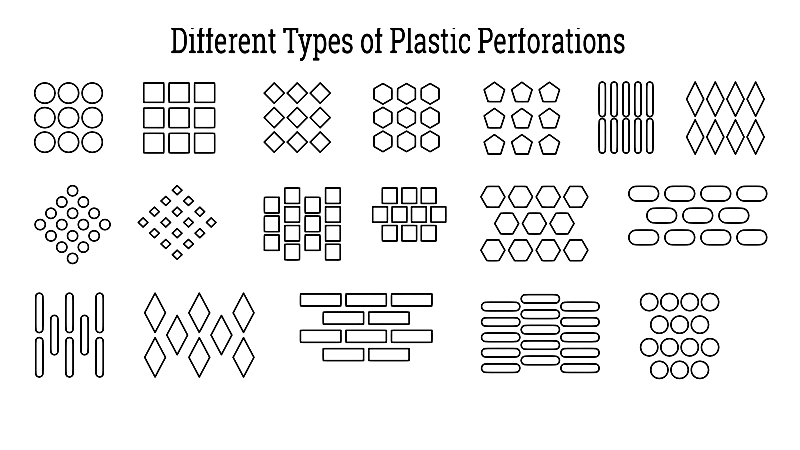

In addition to standard patterns, perforation specialists can create custom designs that complement any architectural style. Using CAD technology, they develop unique shapes and patterns tailored to specific requirements.

The perforation process uses various machines, some capable of producing 400,000 holes per minute. While the technique is straightforward, it requires careful planning including tool selection, perforation spacing programming, and material choice.

Chapter 2: How Perforated Plastic Sheets are Made

Specialized equipment manufactures perforated plastic sheets with precision, speed, and versatility. These machines create accurate patterns and custom configurations for industries including packaging, filtration, agriculture, automotive, medical, and construction. Common perforation methods include hot/cold pin rotary systems, die punch machines, electro pneumatic perforators, laser perforators, mechanical register units, hybrid systems, and sheet-fed equipment. Selection depends on plastic type, thickness, hole size, and pattern complexity.

The optimal method considers material (PE, PP, PVC, HDPE), perforation size/geometry/spacing, and production volume. Some systems create hundreds of thousands of holes per minute, ideal for high-volume manufacturing. Strict tolerances ensure consistent quality for applications like mesh screens, vented packaging, drainage sheets, and sound panels.

Hot and Cold Pin Rotary Perforation

These methods create consistent hole patterns in plastic films and sheets. Hot pin perforation uses heated pins to seal hole edges, reducing fraying and increasing strength for packaging liners, vented wraps, and breathable films. The process feeds plastic substrate through idler rollers to a rotating anvil roller.

The perforating roller, with various pin configurations, interacts with the anvil roller to create evenly spaced holes. Hot pin perforation delivers near-laser quality at lower cost, making it cost-effective for medium-to-high volume production.

The welt reinforcement around each hole makes this method ideal when appearance and strength matter equally. It's commonly used for agricultural films, freezer bags, and produce packaging requiring controlled venting and moisture management.

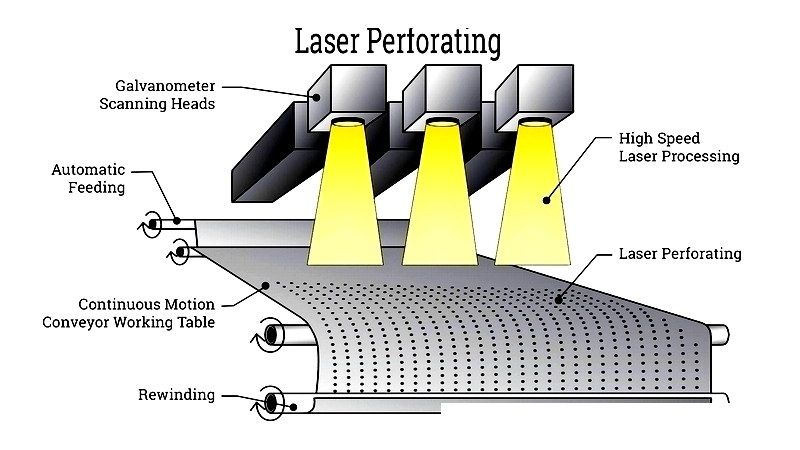

Laser Perforation

This advanced method creates micro-perforations with high precision and clean edges. A focused laser beam produces nano-sized holes (as small as 5 microns) in plastic sheets or films. It's ideal for micro-perforated films in food packaging, medical covers, and breathable membranes requiring controlled air/gas/moisture transmission.

Different laser types (single pulse, percussion, clambering) suit various material thicknesses. Contact-free operation prevents distortion, making lasers ideal for sensitive plastics (PET, BOPP, TPU) requiring precision.

While initial costs are higher, laser perforation excels in applications demanding superior accuracy and design flexibility, such as custom filtration discs and electronics packaging.

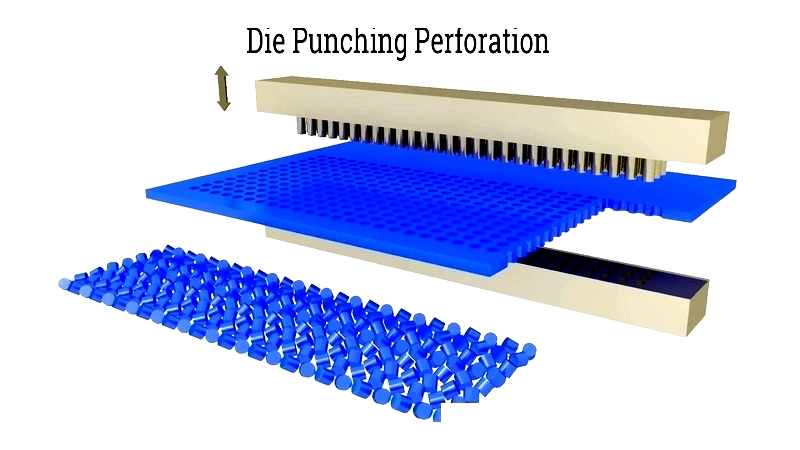

Punch Perforation

This traditional method efficiently perforates both metals and plastics. Rotary or flatbed punch systems use male pins and female dies to shear holes, with vacuum waste removal. It offers excellent porosity control for filter media, screens, and fluid panels.

Adaptable to various plastic thicknesses, punch perforation is favored for high throughput and uniform patterns. It's widely used in construction, filtration, and display manufacturing.

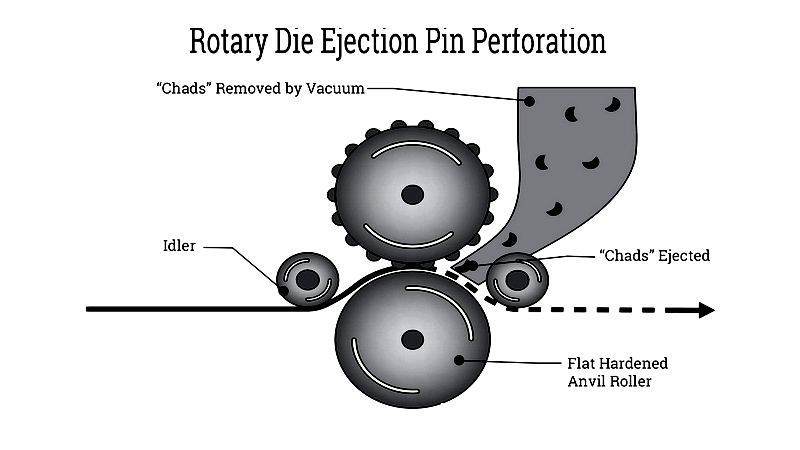

Rotary Die Ejection Pin Perforation

This method uses robust pins to shear material against a rotating anvil, with vacuum waste removal. It's efficient for larger perforations in industrial filtration panels, ventilation screens, and reinforced mesh.

Related rotary die perforation uses synchronized roller dies for simultaneous shearing and waste extraction. Both methods support high-speed production of airflow, drainage, and acoustic applications.

Computer Numerical Control (CNC) Perforating

CNC machining provides automated precision for intricate patterns. Programmed toolpaths create repeatable designs for automotive, aerospace, architecture, and electronics applications.

CNC works well with PP and HDPE due to their thermal tolerance (120-140°C) and chemical resistance. Benefits include design flexibility, fast prototyping, and repeatability for architectural panels, signage, and filters.

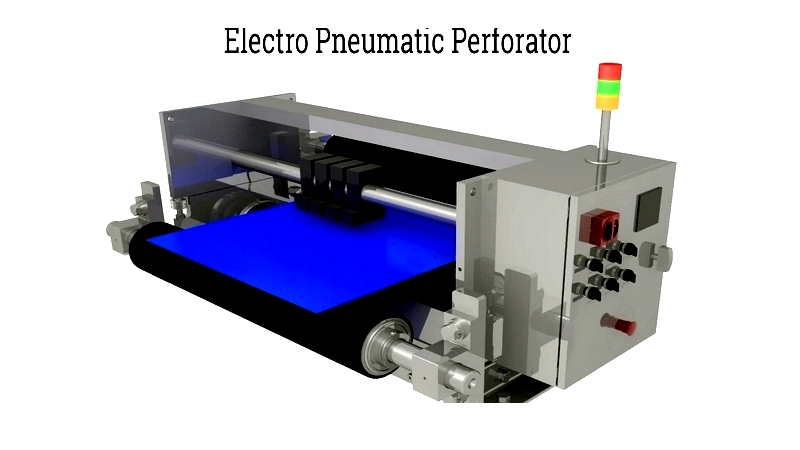

Electro Pneumatic Perforation

This system uses solenoids to actuate dies at high speed, enabling rapid, automated perforation. Configurable as single or gang units, it offers punch control and pattern customization.

Efficient waste removal supports Lean manufacturing. The method excels in short-run custom packaging and printed films requiring quick setup and design changes.

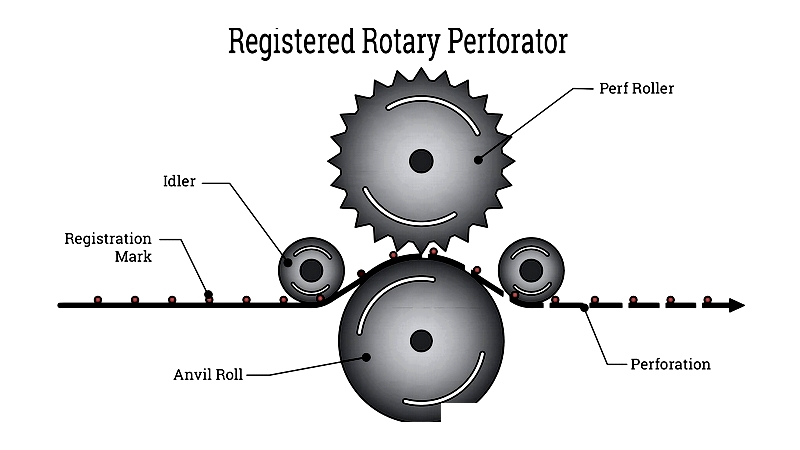

Mechanical Register Perforation

This synchronized method ensures precise hole placement at programmed intervals. Advanced controls maintain accuracy at varying speeds, ideal for security packaging and coupon booklets.

The high-precision approach combines functional design with product presentation, meeting industry standards while supporting high-speed production.

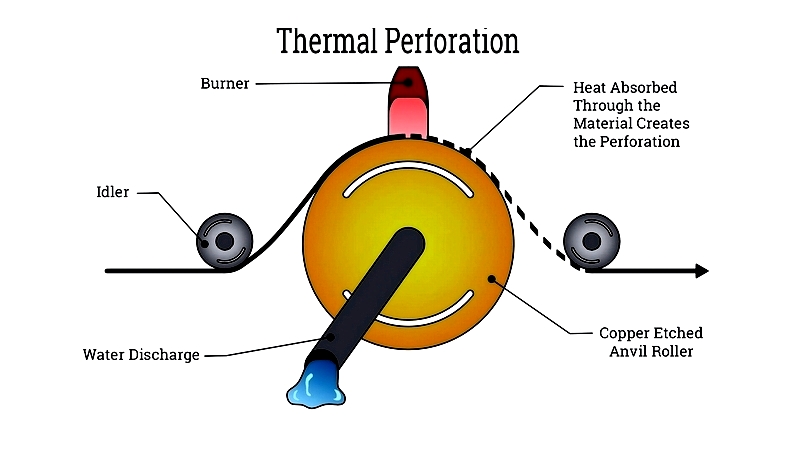

Thermal Perforation (Flame Perforation)

This unique method uses heat to create chad-free holes in plastic films. The heat reinforces hole edges, allowing thinner material use for sustainability.

Ideal for thin packaging films, it creates clean, reinforced holes for breathable food packaging, shrink wraps, and agricultural mulch films requiring controlled air/moisture passage.

In summary, diverse perforation methods enable manufacturers to select the optimal process based on substrate, geometry, throughput, and performance requirements. Understanding these options ensures cost-effective, quality solutions for construction materials, packaging, medical products, and filtration systems.