Introduction

This article provides an in-depth exploration of barrels.

Readers will gain knowledge about various topics including:

- What are Barrels?

- Key Considerations for Barrel Selection

- metal Barrels

- Plastic Barrels

- Different Types of Barrels

- Applications of metal Barrels

- Applications of Plastic Barrels

- Benefits of metal Barrels

- Benefits of Plastic Barrels

- And more...

Chapter One: Understanding Barrels and Key Selection Criteria

Barrel Definition

Barrels are cylindrical containers made from plastic or metal, designed for storing liquids, solids, and powders. They play a vital role in shipping and warehousing operations, with applications ranging from rainwater collection to fuel transportation. Historically, barrels were constructed from wood reinforced with metal hoops, a practice that persisted for centuries.

Modern barrels primarily use metal and plastic materials, which offer greater durability and longevity compared to traditional wooden barrels. Although "drum" and "barrel" originally referred to different capacities (55-gallon and 42-gallon containers respectively), these terms are now used interchangeably. Plastic barrels are commonly made from high-density polyethylene (HDPE), known for its strength, chemical resistance, and ability to withstand extreme pH levels. Government and U.N. regulations require specific coding for barrel identification and classification.

Barrels come in two main designs: closed-head and open-head. Open-head barrels feature removable lids, making them suitable for industries requiring frequent access to contents, such as food and agriculture. Closed-head barrels have sealed tops with dispensing access points, typically used for liquid transportation.

Both plastic and metal barrels are essential for secure storage and transportation, protecting contents from environmental factors. Selecting the right barrel involves evaluating multiple factors including size, shape, material, and intended use.

Key Selection Factors

Material Composition

The stored material's properties (corrosive, acidic, alkaline, liquid, or powdered) determine the appropriate barrel type. metal barrels often feature protective linings like phenolic coatings, making them suitable for abrasive chemicals. Plastic barrels, typically made from HDPE, offer UV resistance and are used for diverse applications including food and chemical storage.

Weight Capacity

Consider both the contents' weight and the barrel's structural capacity. Heavy loads require robust barrels, while lighter materials can use standard designs.

Open vs. Closed Head Design

Open-head barrels allow easy access with removable lids, while closed-head barrels provide secure liquid containment. Forced removal of a closed-head lid typically renders the barrel unusable for certified applications.

Fluid Properties

Liquid viscosity and specific gravity influence barrel selection, especially when using barrel pumps or taps.

Temperature Tolerance

Barrels must withstand the maximum temperature of their contents to maintain structural integrity.

Budget Factors

Balance cost considerations with required quality and durability when selecting barrels.

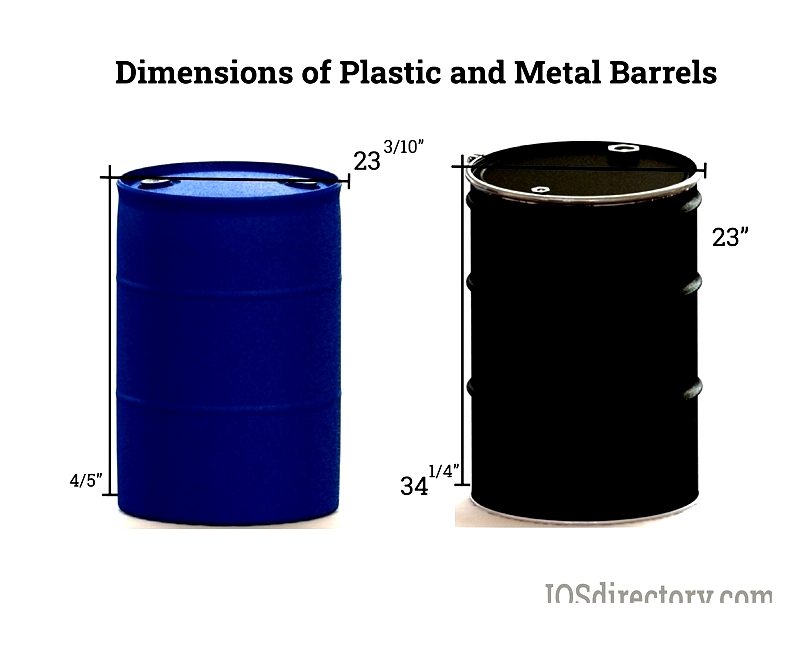

Size Variations

Barrels come in multiple sizes, with 55-gallon being standard. Plastic barrels range up to 95 gallons, while metal barrels extend to 110 gallons. Diameter varies by capacity, affecting pallet compatibility.

metal barrels maintain a cylindrical form and can include accessories like mixers and heaters. Size selection depends on material handling requirements and pallet dimensions.

Chapter Two: Comparing metal and Plastic Barrels

metal Barrel Characteristics

metal barrels, constructed from carbon steel or stainless steel, offer superior strength and impact resistance. Stainless steel variants are preferred for corrosive chemicals. These barrels are reusable and recyclable, providing cost-effective solutions for industrial applications.

Carbon steel contains 0.12%-2% carbon, affecting its hardness, while stainless steel includes chromium for enhanced corrosion resistance. Manufacturing processes like cold rolling improve durability and pressure resistance.

metal barrels serve industries handling hazardous materials, with UN certification for volatile compounds. They ensure secure transport and storage under varying conditions.

- Advantages: High durability, regulatory compliance, recyclability

- Standard sizes: 55-gallon, 30-gallon, 15-gallon

- Industry applications: Chemicals, pharmaceuticals, food processing

Plastic Barrel Features

Plastic barrels, primarily HDPE, provide chemical resistance and UV stability. Their lightweight design reduces shipping costs while maintaining product integrity.

Available in open-head and closed-head designs, plastic barrels accommodate diverse contents from food products to hazardous waste. They meet various regulatory standards for safe transportation.

- Benefits: Lightweight, chemical resistant, cost-effective

- Common uses: Food storage, water containment, agriculture

- Sustainability: Recyclable and reusable

Selection between metal and plastic barrels depends on chemical compatibility, regulatory requirements, and operational needs. Consult manufacturers for tailored solutions.