Introduction

This article provides an in-depth exploration of copper.

It covers detailed information on various topics including:

- What is Copper?

- Copper Production (Extraction)

- Types of Copper Wire

- Copper Applications

- And more...

Chapter 1: Understanding Copper

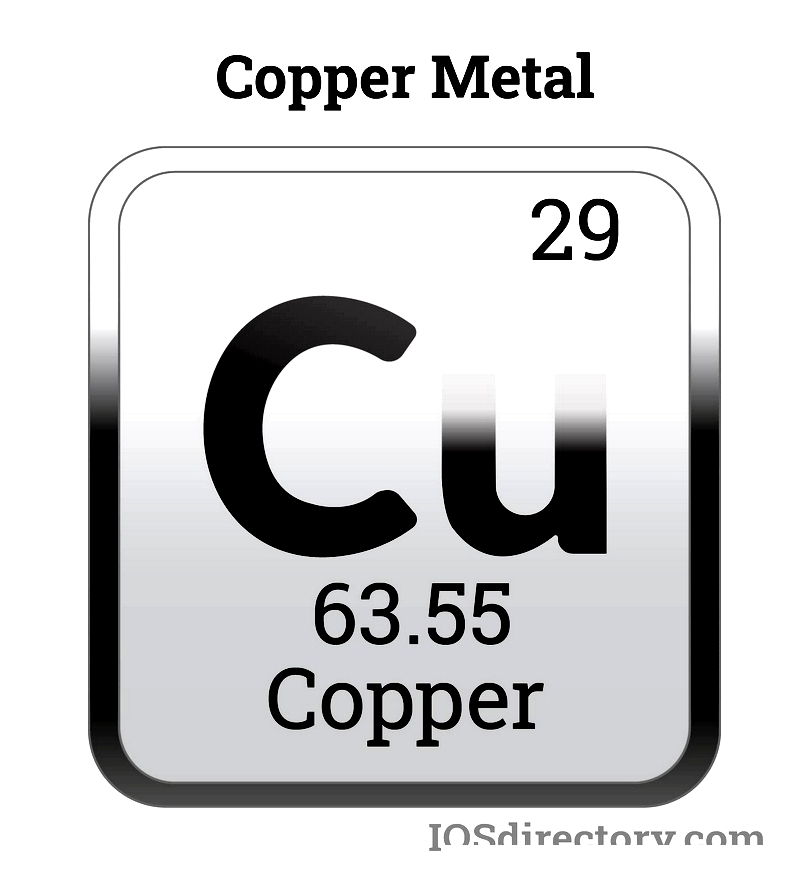

Copper is a malleable metal with a distinctive reddish-gold color, renowned for its excellent thermal and electrical conductivity. Often alloyed with tin and zinc to create brass and bronze, copper oxidizes quickly and is classified as a base metal. With the atomic symbol Cu and number 29 on the periodic table, copper's alloying with tin marked the beginning of the Bronze Age, enabling the production of tools and weapons.

Historically used alongside silver and gold in coinage, copper remains the preferred metal for minting due to its affordability. It forms the base alloy for all US coins and is also utilized in gun metal production.

Available in forms like foil, sheets, rods, wires, and plates, copper is prized for its high electrical conductivity, with refined grades offering even better performance.

Copper's applications span multiple industries. In architecture, it enhances aesthetics and durability in wall tiles and facades, while DIY enthusiasts favor it for decorative bar tops.

The purest copper is grade 101, containing 99.99% copper. The most common grade, 110, is widely used in electrical and architectural applications, strengthened by alloying elements that maintain flexibility while increasing strength.

Primarily used in motors and electrical equipment due to its conductivity and wire-forming capability, copper is also essential in industrial machinery, roofing, and plumbing. Copper sulfate serves as a pesticide in agriculture and an algicide in water treatment. In chemical testing, copper compounds like those in Fehling's solution help detect sugars.

Sources of Copper

Native copper is commonly found in basaltic lava flows and can be extracted from compounds like sulfides, chlorides, arsenides, and carbonates. Notable sources include minerals such as chalcopyrite, bornite, chalcocite, cuprite, malachite, and azurite.

Copper is present in the human liver, certain marine corals, seaweed ash, and many arthropods. In creatures like crustaceans and mollusks, copper functions similarly to iron in human hemoglobin, facilitating oxygen transport via hemocyanin. As a trace metal, copper also aids human hemoglobin production.

Copper's Characteristics

Highly ductile but not inherently strong, copper's properties improve through cold working, which reshapes it below its recrystallization point, creating a face-centered cubic structure. While gases like oxygen and sulfur dioxide can weaken solidified copper, they don't dissolve in molten copper. Pure copper's thermal and electrical conductivity is second only to silver, with natural copper mainly consisting of stable isotopes copper-63 and copper-65.

Copper reacts minimally with hydrogen-acidic environments but interacts with oxidizing acids like nitric and hot sulfuric acids. While resistant to seawater and air, prolonged exposure forms a green patina of hydroxycarbonate and hydroxysulfate. In oxygen-free conditions, non-oxidizing acids have little effect, making copper relatively noble.

In oxygen's presence, copper dissolves in sulfuric and nitric acids, as well as in aqueous ammonia or potassium cyanide, forming stable cyano complexes.

Varieties of Copper

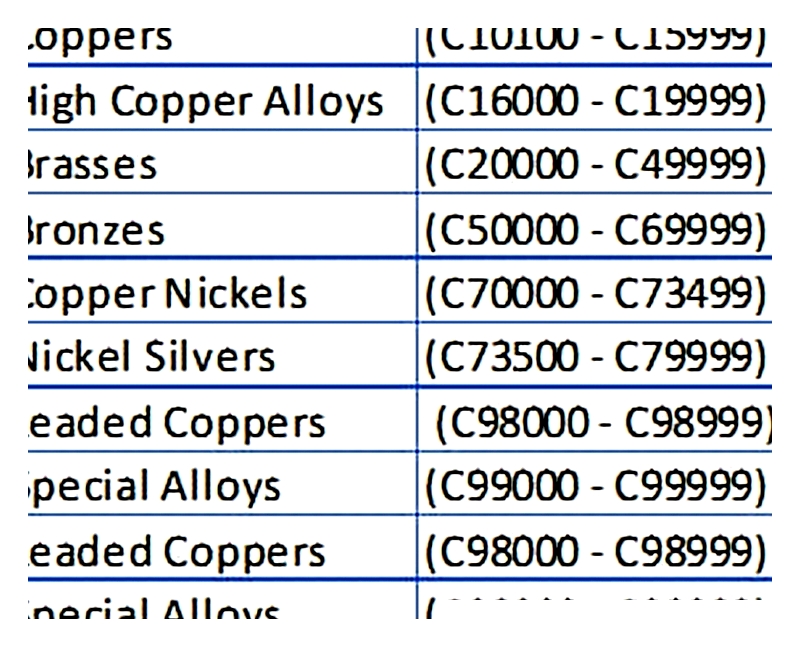

Copper grades fall into six categories: pure copper, dilute copper alloys, brass, bronze, copper-nickel alloys, and nickel-silver alloys. These are classified by the Unified Numbering System (UNS) developed by ANSI and managed by SAE and ASTM.

Pure copper grades (UNS C10100-C13000) contain under 0.7% impurities. Dilute copper grades include small alloy additions for customized properties, such as C11000's superior electrical conductivity. Copper-nickel alloys (1.5%-4.5% nickel) are labeled UNS C70000-C73499.

Different grades are selected based on desired traits. Grades C70000-C73499 are used for coins, evaporators, and heat exchanger tubes, while C73500-C79999 grades are used in ballpoint pens, musical instruments, and transistor casings.

Chapter 2: Copper Production (Extraction) Process

Copper is a crucial industrial metal valued for its conductivity and malleability. Found in copper mineral deposits often mixed with other base metals, copper extraction begins with mining, primarily through open-pit (90% of global production) or underground methods.

Global copper demand continues rising with investments in energy infrastructure, telecommunications, renewable energy, and electric vehicles. China leads consumption (52%), followed by Europe (16%). Chile tops production, with Peru, China, and the US also significant contributors. Beyond pure metal uses, copper is key in alloys like bronze and brass.

Underground mining accesses deep deposits via shafts and tunnels, employing advanced technology for efficient extraction with minimal environmental impact.

Post-mining, copper ore undergoes processing to achieve industrial-grade purity. Sulfide and oxide ores require different refining methods:

Sulfide Ore Processing

Sulfide copper ores are refined through five steps:

- Comminution crushes and grinds ore to liberate copper particles.

- Flotation uses chemicals to separate hydrophobic copper minerals from gangue.

- Air bubbles carry copper minerals to the surface as froth.

- Copper-rich froth is thickened and smelted into anode slabs.

- Electrorefining purifies anodes into 99.99% pure cathodes for electrical applications.

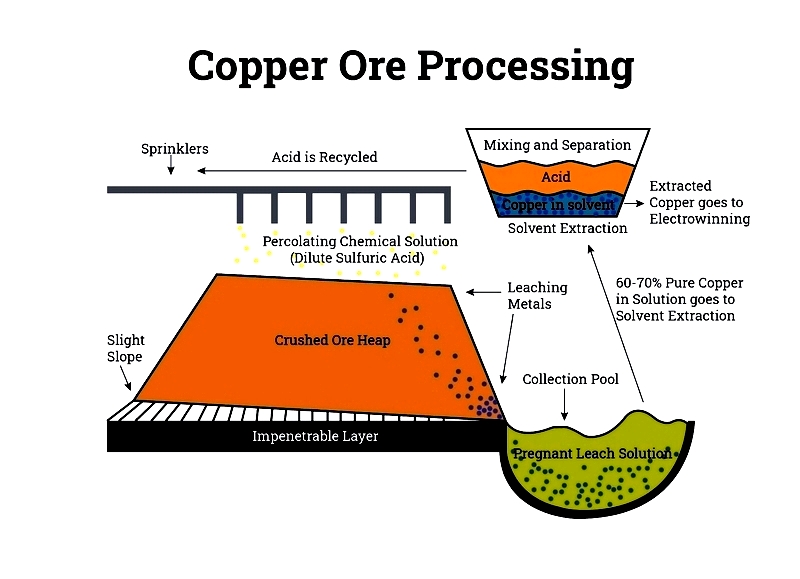

Oxide Ore Processing

Oxide copper ores undergo hydrometallurgical treatment:

- Heap leaching uses sulfuric acid to dissolve copper from ore.

- Solvent extraction purifies the copper-containing solution.

- Electrowinning plates copper ions onto cathodes for high-purity metal.

Both smelting and leaching methods meet industry standards, with modern refineries emphasizing efficiency and sustainability.

Beyond pure metal uses, copper is vital in electrical components, electroplating, and alloys like brass, bronze, and nickel-silver. Specialized alloys like Monel® and beryllium copper offer unique properties for demanding applications.