Introduction

This article provides detailed information about high pressure boilers and their applications.

You will learn about:

- What constitutes a High Pressure Boiler

- Different types of High Pressure Boilers

- Key characteristics of High Pressure Boilers

- Heat sources used in High Pressure Boilers

- And additional relevant information

Chapter One – What is a High Pressure Boiler?

A high-pressure boiler operates at pressures exceeding 80 bars and is primarily used in thermal power plants for electricity generation. This boiler type converts water into steam through thermal energy within water-filled tubes enclosed in a sturdy metal casing. The produced steam then powers various machinery.

What distinguishes high-pressure boilers is their capacity to generate substantial pressure. This pressure and steam result from burning fuels such as coal, natural gas, or oil. Heated gases circulate either naturally or through pump propulsion. Using centrifugal pumps for forced circulation increases evaporation rates to 210 kPa per square centimeter, as natural convection alone cannot achieve the necessary high pressures.

High-pressure boilers come in various types like steam generators and electric boilers, with designs including vertical, horizontal, gas, water-tube, and fire-tube configurations. These boilers share a common feature of small-diameter tubes that increase heating surface area and improve heat transfer efficiency.

In fire-tube boilers, hot gases pass through tubes submerged in water, heating the water to produce steam, as shown in the following image.

Chapter Two – Types of High Pressure Boilers

Most industrial boilers work on the basic principle of converting heated water into steam for energy production, heating, or industrial processes. High-pressure boilers differ in their geometric orientation, combustion chamber placement, operating steam pressure, water circulation methods, tube quantity, heat transfer techniques, and exhaust gas systems.

Boiler orientation can be horizontal or inclined, affecting efficiency and space requirements. The furnace location is crucial - some have internal combustion chambers while others are externally fired, depending on energy needs and space constraints. Boilers are classified by pressure ratings: those above 80 MPa are high-pressure, while those below are low-pressure. High-pressure steam boilers are essential for thermal power plants, chemical processing, and large-scale manufacturing where efficiency and high steam capacity are required.

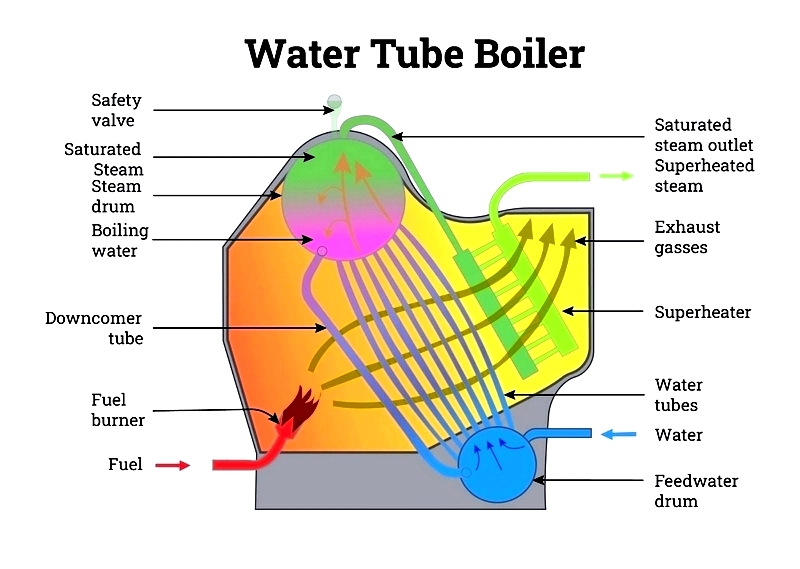

Water circulation methods include forced circulation (using pumps) and natural circulation (relying on convection currents), which affect heat exchange rates and operational control. Gas circulation varies between fire-tube boilers (hot gases through tubes surrounded by water) and water-tube boilers (water through tubes heated externally). Modern high-efficiency boilers often use water-tube designs for faster high-pressure steam generation.

Boilers may have single or multiple tubes. Traditional Cornish boilers use a single fire tube, while advanced multi-tube designs increase surface area for better heat transfer and higher thermal efficiency, making them suitable for high-demand applications.

Types of High Pressure Boilers

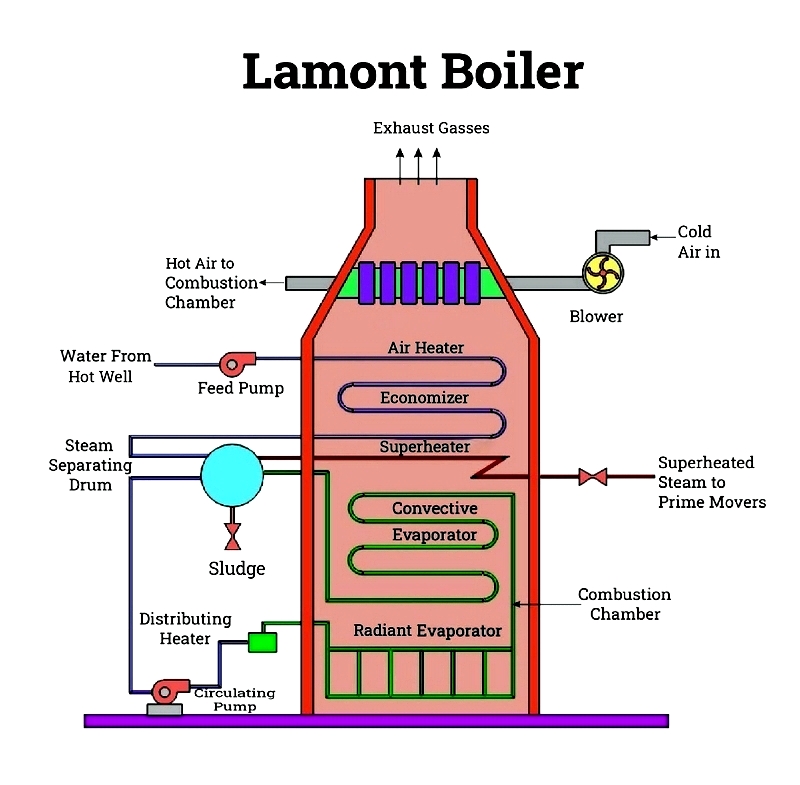

La Mont Boiler

The Lamont boiler is a forced convection water-tube boiler known for reliable performance in power plants and industries requiring rapid steam generation. Its centrifugal pump circulates water at high velocity through small tubes, reducing scale formation and thermal stress risks. Key components include the economizer, air preheater, steam drum, superheater, and evaporator section. Water circulates from the economizer to the boiler drum, where feed water is efficiently distributed into evaporator tubes.

The boiler drum separates steam from water to prevent wet steam from reaching sensitive equipment. The steam then moves to the superheater for further heating, making the La Mont boiler ideal for high-pressure steam power plants where reliability and efficiency are crucial.

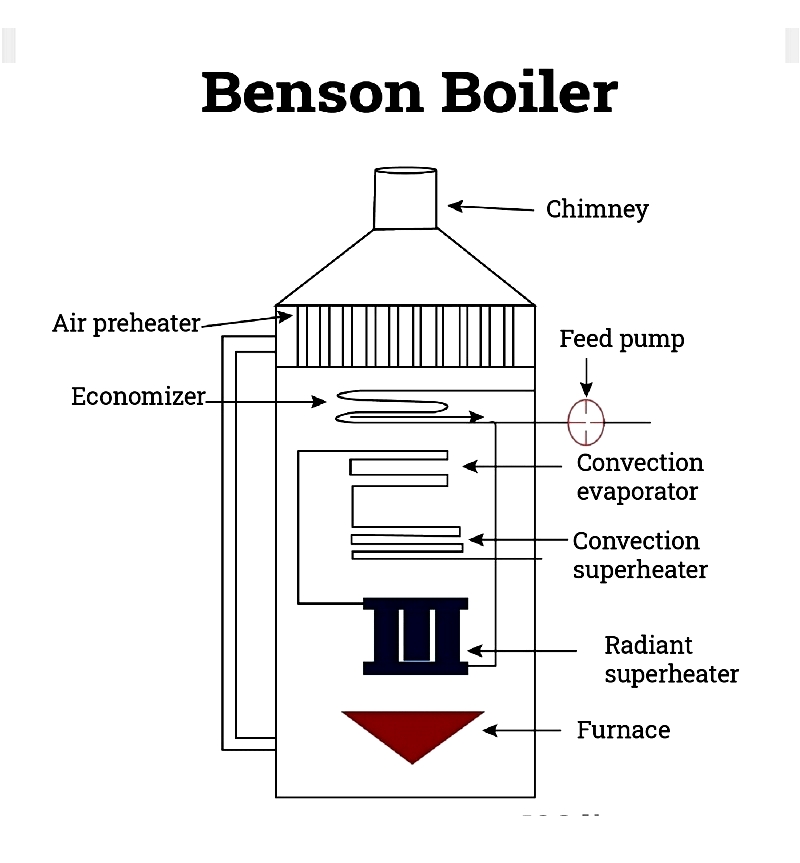

Benson Boiler

The Benson boiler shares features with the Lamont boiler but operates at supercritical pressure without needing a steam separator or drum. Feedwater is compressed beyond water's critical pressure, eliminating phase distinction and bubble formation. This supercritical process reduces metallurgical stress while improving heat transfer and thermal efficiency.

Key components include an air preheater, economizer, superheater, evaporator, and combustion chamber. The Benson boiler's ability to produce high-quality, dry steam quickly makes it ideal for modern thermal and combined-cycle power plants.

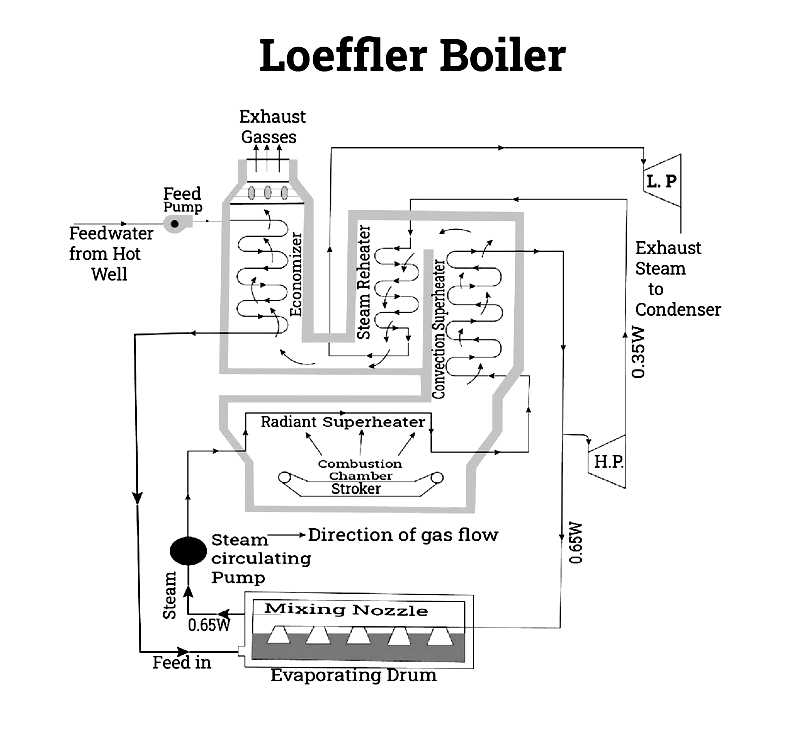

Loeffler Boiler

The Loeffler boiler addresses scaling issues by circulating superheated steam instead of feedwater. High-pressure water in tubes converts to steam through radiant heating before entering the superheater system.

With both radiant and convective superheaters, the Loeffler boiler ensures maximum steam temperature and quality for power generation and petrochemical processing.

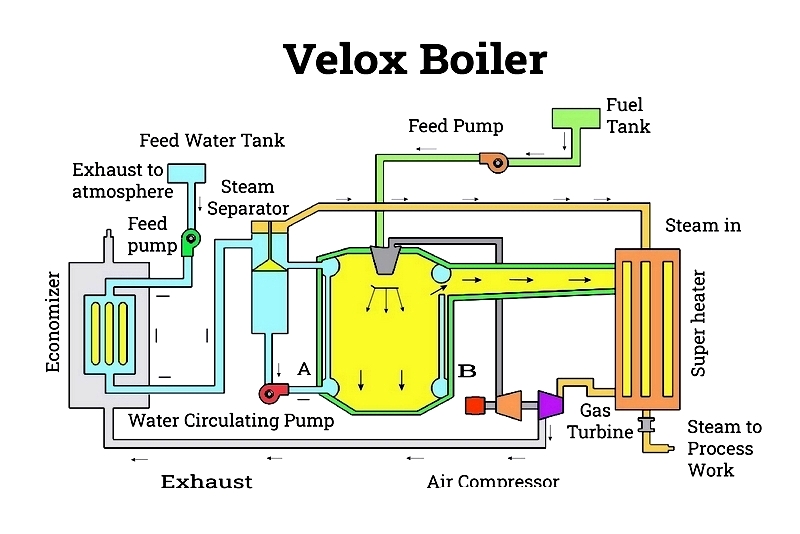

Velox Boiler

The Velox boiler uses a gas turbine-driven compressor to supply high-velocity air into the combustion chamber, enhancing heat transfer rates. Steam is separated in a water separator and processed in a flue gas-heated superheater.

Its quick response, compact size, and high-pressure steam generation make the Velox boiler suitable for industrial cogeneration and chemical manufacturing.

Cornish Boiler

The Cornish boiler is a classic fire-tube boiler with a single horizontal flue tube surrounded by water. While typically low-pressure, modern versions can handle moderate pressures. Its simple design with a grate, single fire tube, and steam dome makes operation and maintenance easy.

Fuel combustion produces hot gases that flow through the central tube, heating surrounding water to create steam. Cornish boilers are valued for their robust construction and suitability for smaller-scale industrial needs.

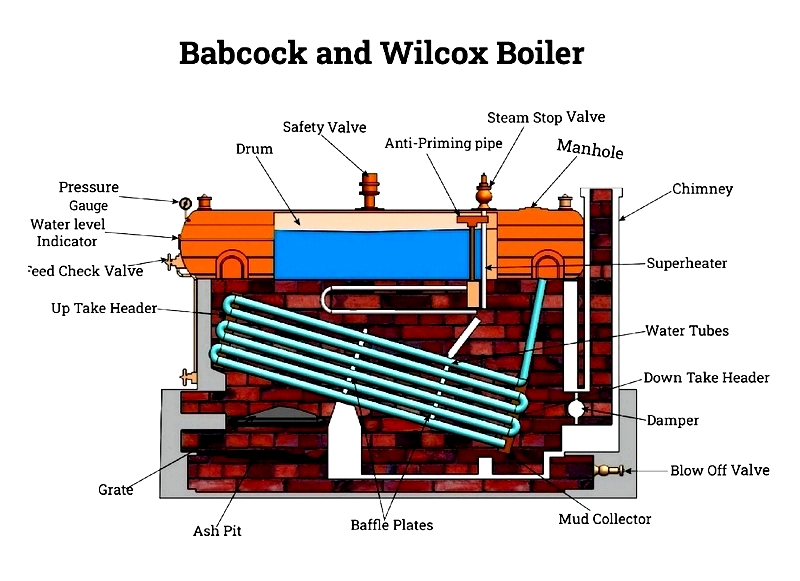

Babcock and Wilcox Boiler

The Babcock and Wilcox boiler is a benchmark in industrial water-tube design, known for efficiency and reliability. This horizontal, externally fired boiler uses natural circulation through inclined tubes heated by combustion gases. Water moves in a zigzag pattern for optimal heat transfer.

Steam collects in the drum where water droplets are removed before superheating. Its modular construction and high steam output make it ideal for power stations and industrial processes requiring continuous high-pressure steam.

Selecting the Right High-Pressure Boiler

Choosing the appropriate high-pressure boiler depends on steam pressure requirements, fuel type, application needs, and site considerations. Water-tube boilers like Lamont, Benson, Loeffler, and Babcock & Wilcox designs are preferred for large-scale industrial systems due to their heat transfer efficiency and high-pressure capabilities. Fire-tube boilers like the Cornish design suit smaller applications.

When evaluating options,