Introduction

This article provides an in-depth exploration of carbon dioxide lasers.

Key topics covered include:

- Working Principles of Carbon Dioxide Lasers

- Different Types of Carbon Dioxide Lasers

- Applications and Advantages of Carbon Dioxide Lasers

- Additional Related Information

Chapter 1: Fundamental Principles of Carbon Dioxide Lasers

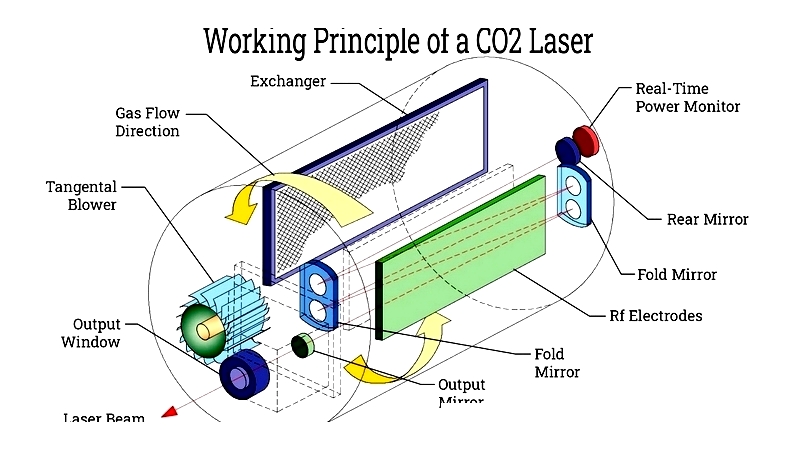

This section examines the core principles behind carbon dioxide lasers, focusing on their design, key components, and operational mechanisms.

Understanding Carbon Dioxide Lasers

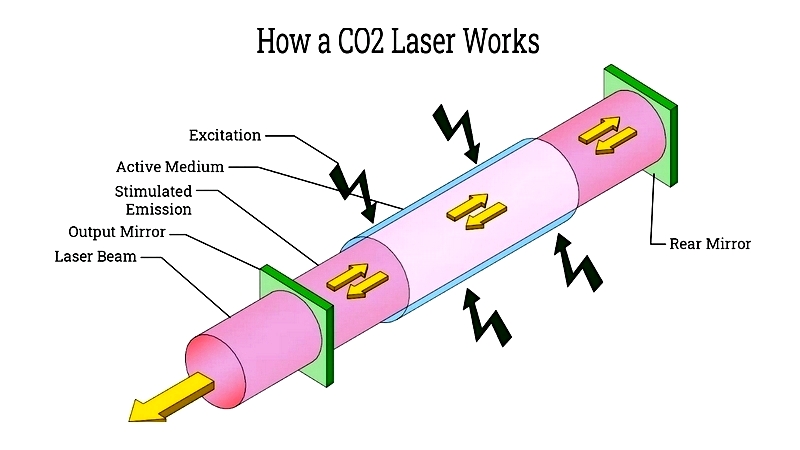

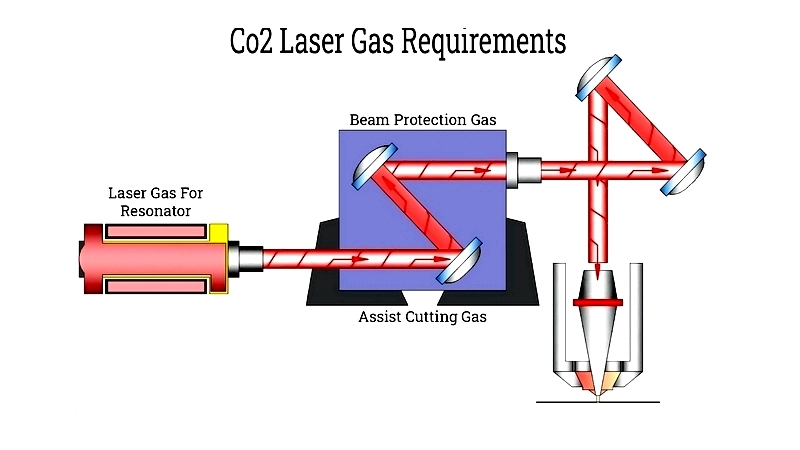

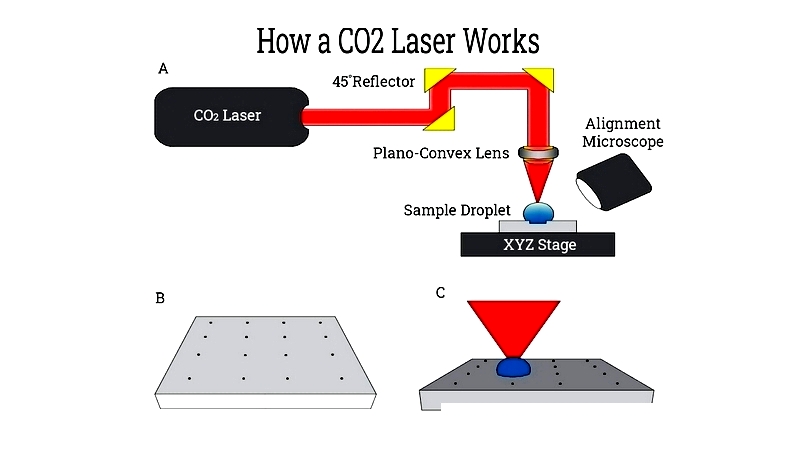

A carbon dioxide laser utilizes CO2 as its primary gain medium, often supplemented with nitrogen (N2), helium (He), and occasionally hydrogen (H2), water vapor, oxygen, or xenon (Xe) to enhance performance. The system operates through electrical gas discharge, which excites the gas mixture to produce laser light.

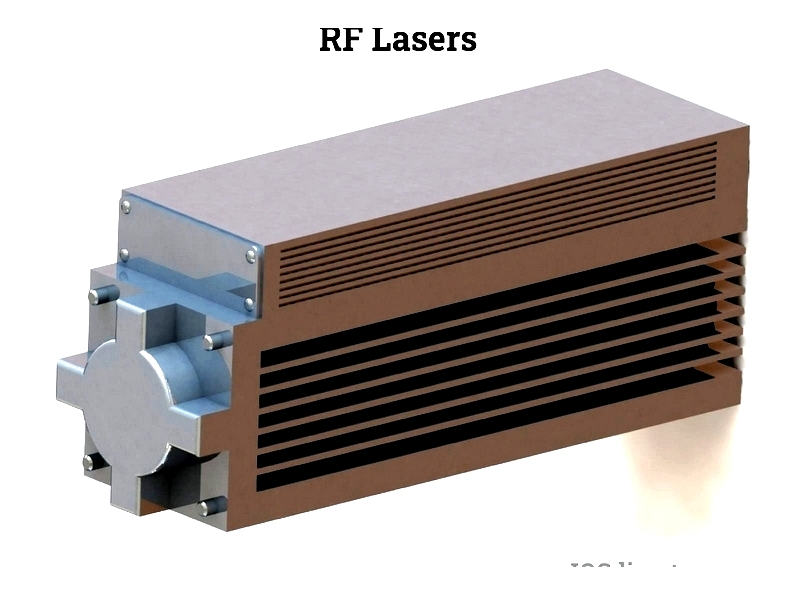

These lasers can be powered by alternating current (AC), direct current (DC), or radio frequency (RF) energy. Emitting at 10.6 micrometers, they're extensively used in dermatology for scar removal, wrinkle reduction, and skin treatments, as well as in surgical applications requiring precision cutting.

Structural Components

Carbon dioxide lasers consist of several essential elements:

Construction Materials

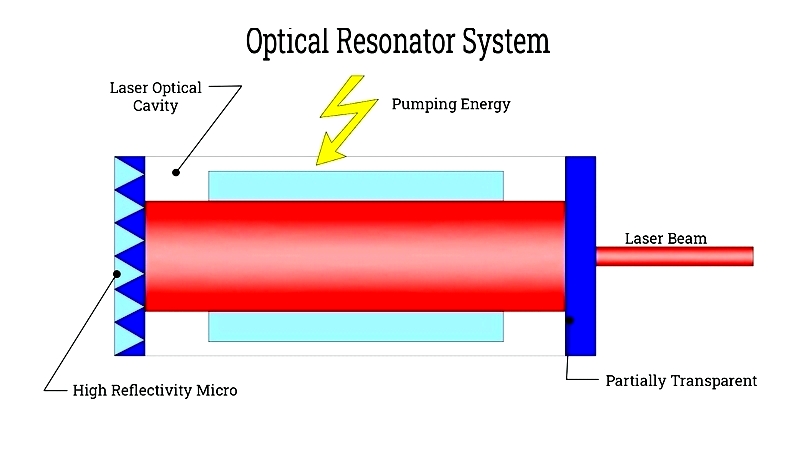

Given their infrared operation, CO2 lasers require specialized materials. Mirrors typically feature silver coatings, while windows and lenses use germanium or zinc selenide. High-power applications may employ gold-coated mirrors and diamond components.

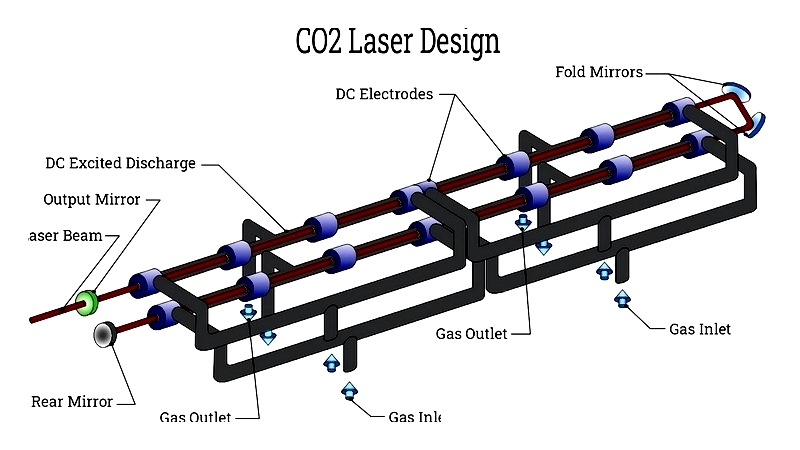

Design Specifications

The core component is a quartz discharge tube (approximately 2.5 cm diameter and 5 meters long) containing a CO2-N2-He gas mixture (1:2:3 ratio) with added water vapor. Operating pressures are maintained at 7 Torr (He), 1.2 Torr (N2), and 0.33 Torr (CO2). Laser action occurs through vibrational-rotational transitions in CO2 molecules, producing continuous output.

Active Medium Composition

The active medium combines CO2, N2, and He in a 1:2:3 ratio, with CO2 molecules serving as the primary emission centers.

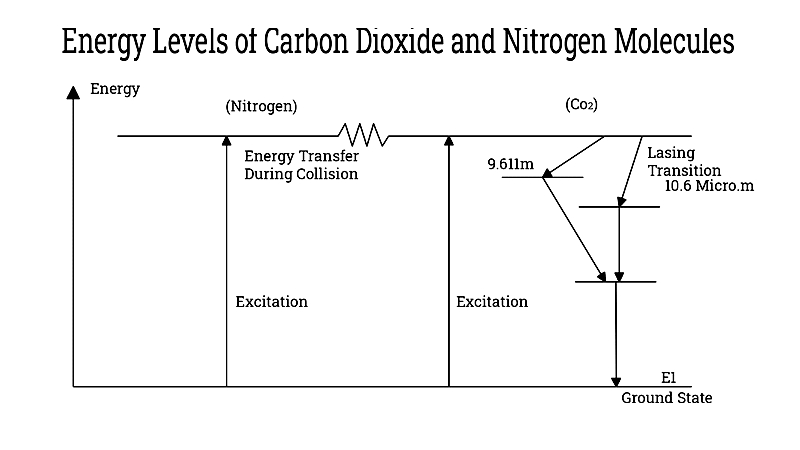

Energy Pumping Mechanism

Electrical discharge creates population inversion by energizing CO2 molecules through electron collisions.

The process involves:

N2 + e* → N2* + e

Where:

N2 = Ground state nitrogen

e* = Energetic electron

N2* = Excited nitrogen

e = Lower-energy electron

Excited nitrogen then transfers energy to CO2:

N2* + CO2 → CO2* + N2

This creates population inversion in CO2's E5 level, enabling laser transitions at either 10.6μm (E5→E4) or 9.6μm (E5→E3), with typical outputs reaching 10kW.

Optical Resonator Configuration

The gas mixture sits between two mirrors (one fully reflective, one partially reflective). Given their infrared operation and high power, optical components use specialized materials like zinc selenide or gold.

Operational Process

Key operational stages include:

Beam Generation

Electric current excites nitrogen molecules, which transfer energy to CO2, creating population inversion. Photon emission occurs when excited nitrogen interacts with cool helium atoms.

Helium helps depopulate lower energy levels, while water vapor assists in CO2 regeneration from CO byproducts.

Emission Characteristics

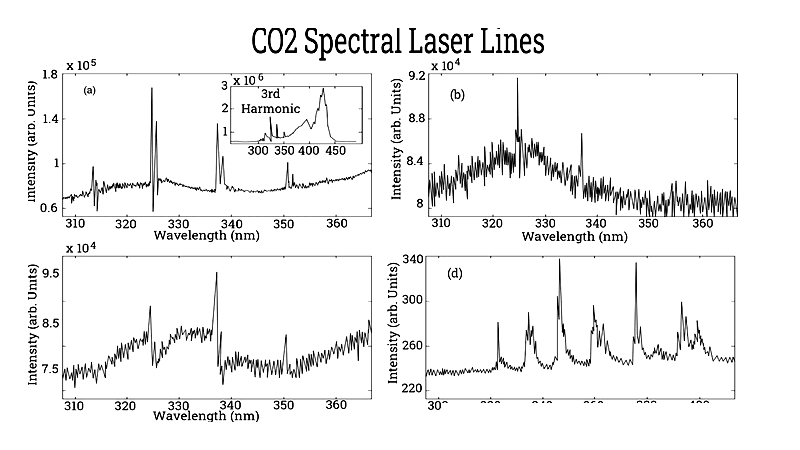

Primary emission occurs at 10.6μm, with secondary lines at 9.6μm due to vibrational-rotational transitions. The P branch (Δj = -1) dominates at 10.6μm, while the R branch (Δj = +1) appears at higher energies.

Some specialized models emit at alternative wavelengths (e.g., 9.3μm) for enhanced material absorption.

Performance Metrics

Typical outputs range from tens of watts to kilowatts, with 10-20% conversion efficiency. While requiring specialized optics, their long wavelengths pose reduced eye hazards compared to visible lasers.

Discharge Dynamics

Nitrogen excitation and subsequent energy transfer to CO2 remains fundamental to population inversion.

Gas Mixture Maintenance

Catalytic additives (H2O/H2) help regenerate CO2 from discharge byproducts.

Key Attributes

- Molecular gas laser type

- Active medium: CO2-N2-He mixture

- Electrical discharge pumping

- Concave mirror resonator

- ~10kW output power

- Continuous/pulsed operation

- 9.6μm and 10.6μm wavelengths

Working Principle

Laser transitions occur between vibrational states of CO2 molecules in a N2-He-CO2 mixture.

Core Components

Three essential elements:

Electrical Excitation

Current energizes the gas medium.

Gas Composition

Typical ratio: 1:1:8 (CO2:N2:He), adjustable for specific applications.

Infrared Optics

Specialized materials (Ge, ZnSe, etc.) handle high-power infrared beams.

Chapter 2: Varieties of Carbon Dioxide Lasers

Major types include longitudinal-flow, transverse-flow, sealed-off, waveguide, and TEA lasers, each suited for specific industrial/scientific applications.

Flow Configuration Lasers

Employ continuous gas flow through discharge tubes for high-power stability.