Introduction

This article provides a comprehensive examination of rubber-to-metal bonding.

Key topics covered include:

- Principles of Rubber-to-metal Bonding

- Rubber Bonding, Rubber Products, and Silicone Bonding

- Applications and Advantages of Rubber-to-metal Bonding

- Additional relevant information

Chapter 1: Fundamentals of Rubber-to-metal Bonding

This chapter explores the core principles of rubber-to-metal bonding, examines the characteristics of bonded rubber, and discusses various techniques for joining rubber to metal surfaces.

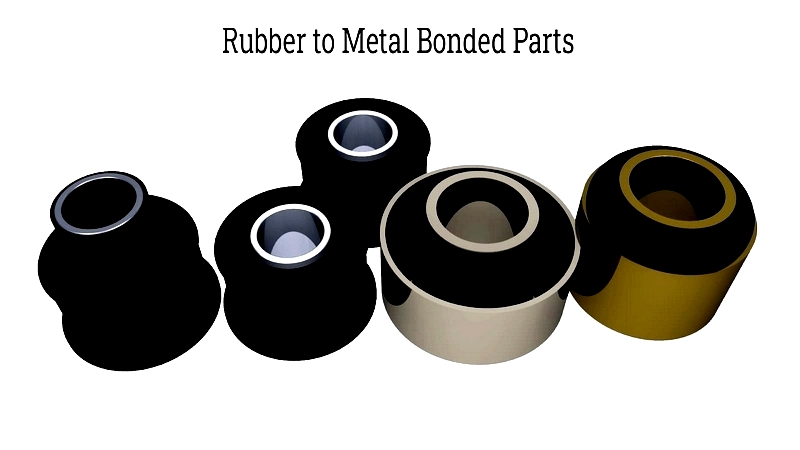

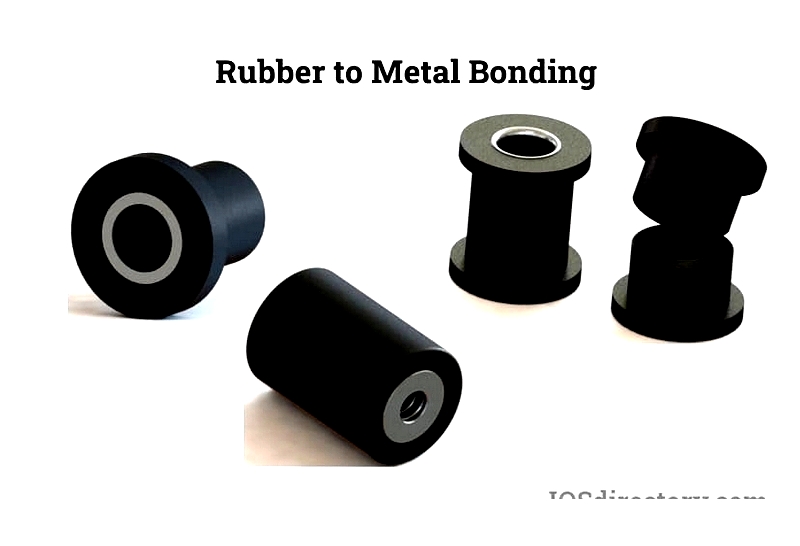

Rubber-to-metal Bonding Overview

Rubber-to-metal bonding creates durable connections between rubber and metal components. Common adhesives include rubber-based adhesives, silicone-based glues, two-part adhesives, polyurethane solutions, and epoxy resins.

Rubber-based adhesives are widely used for their strong bonding and flexibility. Two-component adhesives with polyurethane solutions are preferred for applications requiring maximum bond strength. The choice of adhesive depends on environmental conditions and industry requirements.

Molding and adhesion are primary methods for combining metal and rubber. The selection depends on production volume, space constraints, manufacturing speed, and equipment costs.

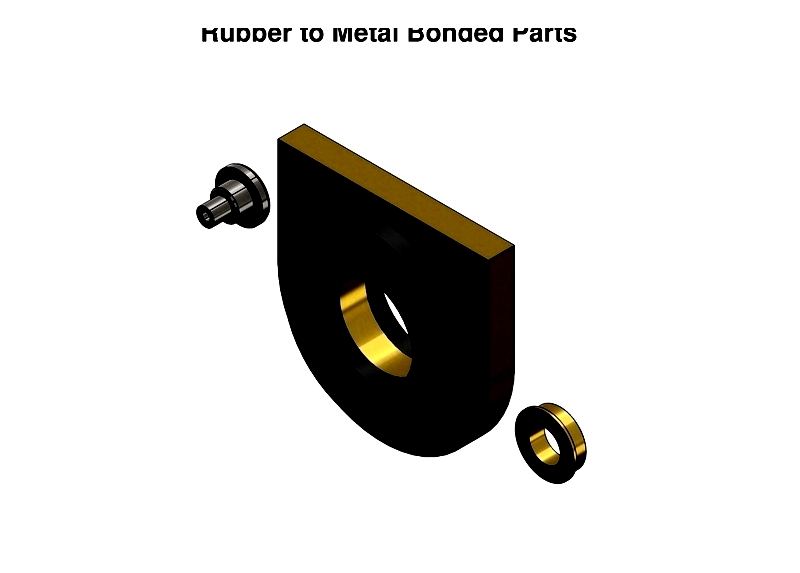

Several molding techniques are available:

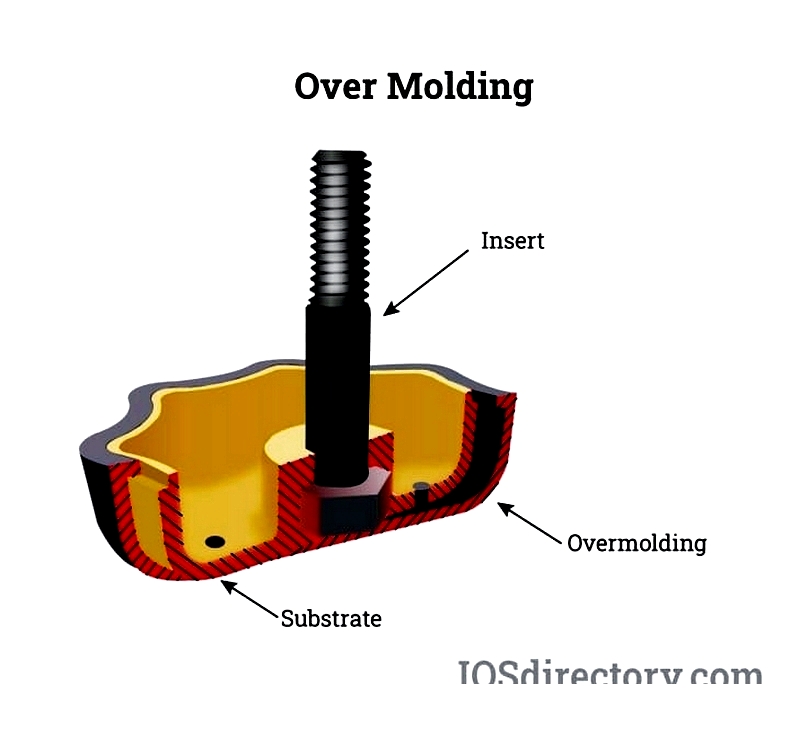

Over Molding

Over molding coats metal substrates with rubber, creating components where both materials remain visible. This multi-layer method is commonly used for seal manufacturing.

Total Encapsulation

Complete encapsulation involves placing metal inserts into molds before adding rubber. Also called insert molding, this method produces components with minimal metal visibility, often used for o-rings with wiring.

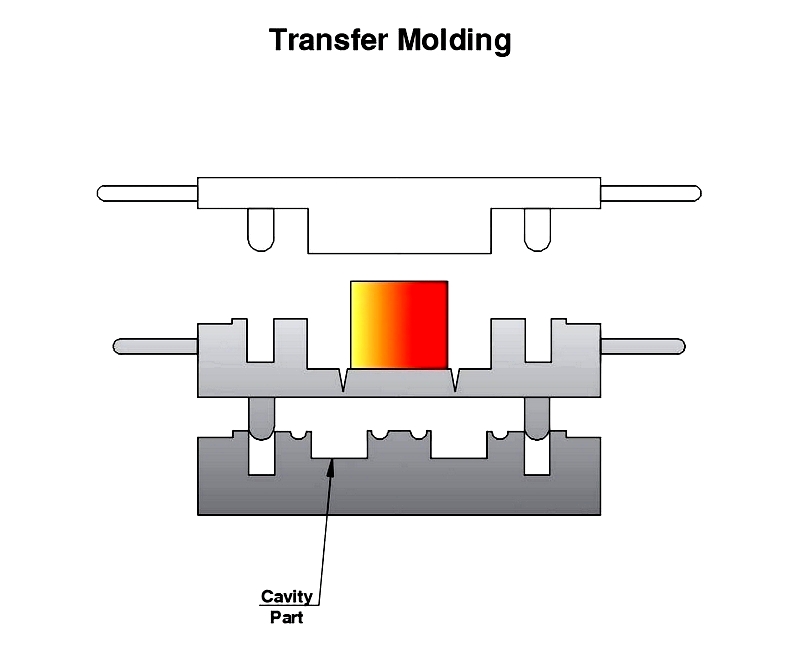

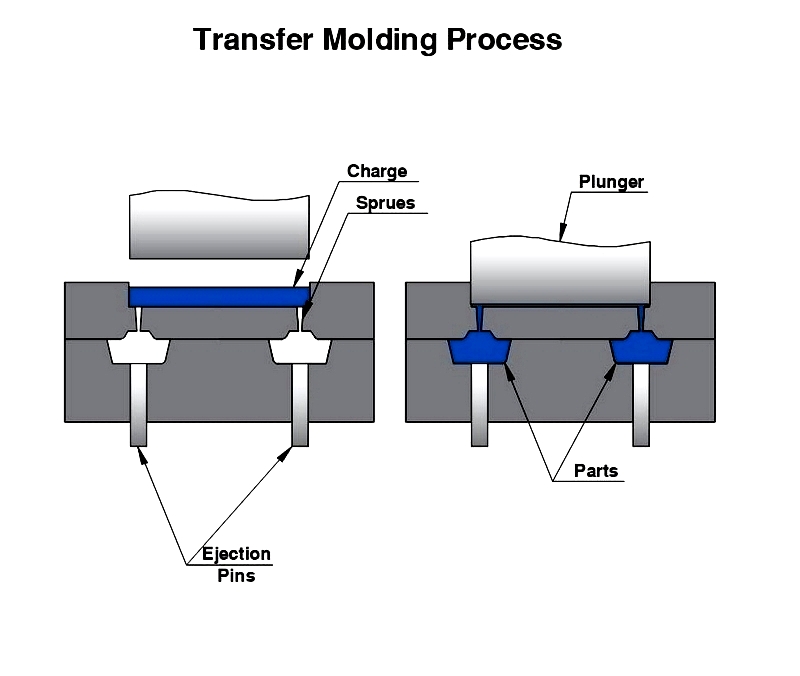

Transfer molding and injection molding are the most common rubber-to-metal bonding methods.

Transfer Molding Process

In transfer molding, metal parts are placed in preheated molds. Solid rubber is then forced into the mold by a heated plunger, surrounding the metal components to form bonds.

The assembly is then cured and vulcanized under high heat and pressure.

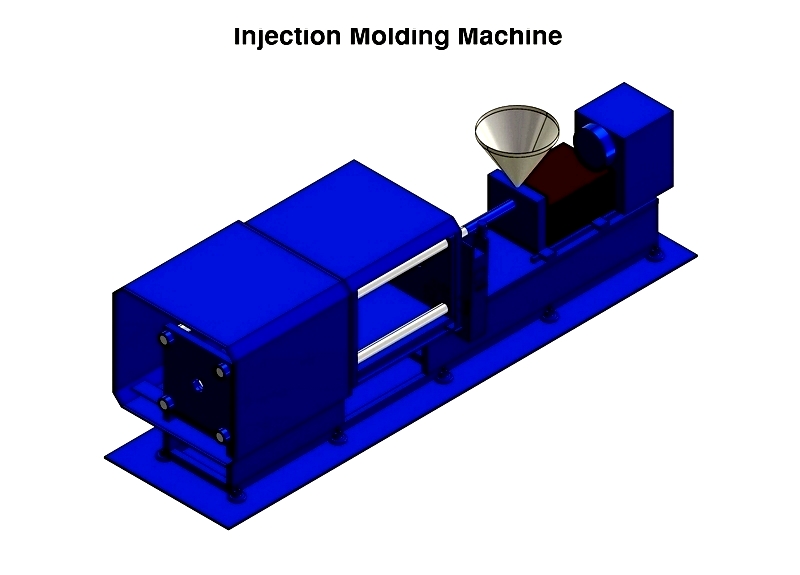

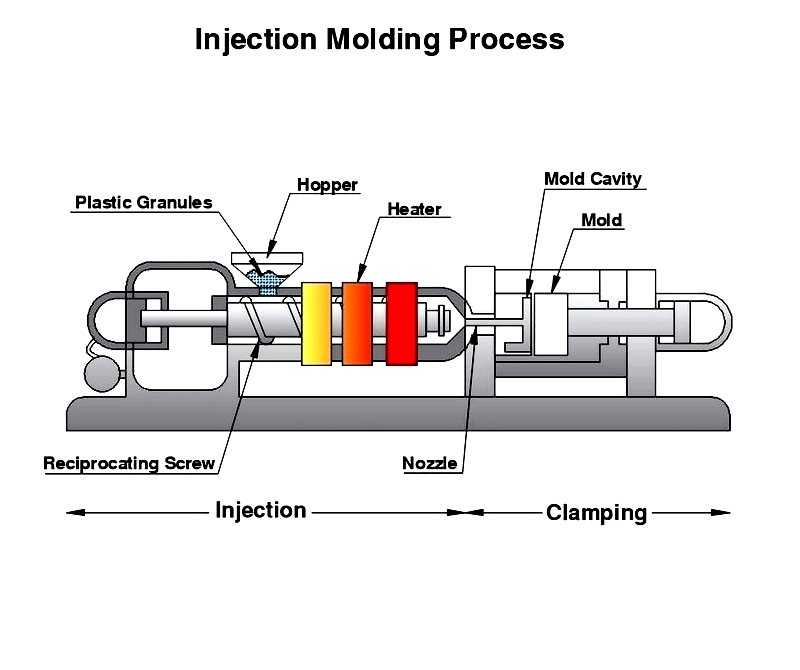

Injection Molding

Similar to transfer molding, this process begins by placing metal parts into molds.

Liquid elastomer is injected into the mold, then cured and vulcanized before part removal.

Compression Molding

Compression molding uses closed molds where uncured rubber preforms are placed into heated cavities. High-pressure clamps shape the rubber, which cures under heat and pressure.

After curing, the rubber solidifies and is ejected for trimming and testing.

Rubber-to-metal Bonding Steps

The bonding process involves these key steps:

Elastomer Preparation

Vibration isolation mounts typically use natural rubber or neoprene. Raw materials are blended with additives and fillers, then processed through rollers for even distribution.

The mixed rubber is shaped into pellets for transfer molding or strips for injection molding, stored in climate-controlled conditions before curing.

Post-vulcanization, natural rubber offers excellent mechanical properties including tensile strength and abrasion resistance, suitable for -40°F to 190°F environments.

Neoprene, polymerized from chloroprene, shares similar properties with better oil resistance (-30°F to 212°F), commonly used in pump-related industries.

Surface Preparation

Effective bonding requires slightly rough, oil-free metal surfaces. Phosphate dipping removes oil and adds rust resistance. Alternatives include grit blasting or machining.

Alkaline cleaning or solvent degreasing removes oils, while aluminum oxide grit blasting eliminates rust. Cleaned parts should be stored in low-humidity environments.

Various metals including steel, aluminum, and copper are used, selected based on application requirements.

Primer and Adhesive Application

Cleaned surfaces receive a two-layer adhesive system (primer base and adhesive topcoat) for bonding rubber to low carbon steel.

Application methods include dipping, rolling, spraying, or brushing, with recommended thicknesses of 0.2-0.4 mil for primer and 0.5-1 mil for adhesive.

Components dry at room temperature or in circulating air ovens. Immediate molding prevents surface contamination.

Molding Process

Natural rubber and neoprene typically undergo transfer or injection molding at temperatures up to 340°F, with adhesive-coated components placed in heated molds.

Testing

Quality assessment involves breaking sample pieces to verify tensile strength, with breaks occurring in rubber rather than bonds. Load deflection tests may also verify accuracy.

Bonded Rubber Characteristics

Bonded rubber provides continuous surfaces for exterior applications, combining rubber mulch with binding compounds for organic aesthetics. It exceeds safety standards with superior shock absorption.

This slip-resistant material stays in place, performs well in humid or cold conditions, and resists microbial growth. Its durability and design versatility make it ideal for playgrounds and trails.

Available in various colors, bonded rubber offers more visual options than poured rubber materials.

Rubber-to-metal Adhesion

Material properties influence adhesive selection for rubber-to-metal bonds, with application scope and bonding surface size determining optimal choices.

Cyanoacrylate superglues work for small areas, while two-part adhesives suit larger surfaces. Polychloroprene-based contact adhesives handle expansive areas effectively.

Surface preparation is critical, involving solvent cleaning or abrasion for coated metals. Testing small samples before full application is recommended.

Cured adhesives allow modifications like drilling and effectively fill imperfections, particularly useful for aluminum assemblies.