Introduction

This section explains pressure sensors and their functions, along with a list of pressure sensor manufacturers.

You will learn about:

- What a Pressure Sensor is

- Different Types of Pressure Sensors

- Applications of Pressure Sensors

- How Pressure Sensors Function

- And much more...

Chapter 1: What is a Pressure Sensor?

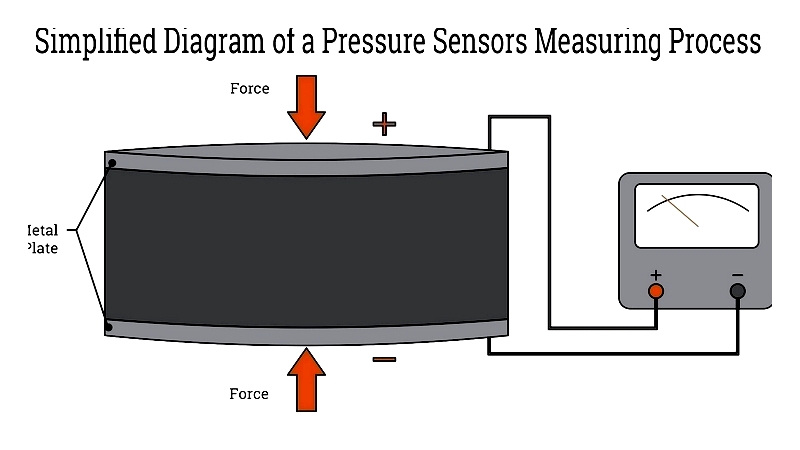

A pressure sensor is a device that detects and measures the force applied to a surface. It provides real-time data about equipment status and helps predict potential failures. These sensors convert physical changes into electrical signals, which are transmitted as analog or digital outputs.

The most common type is the strain gauge sensor, which measures pressure through material deformation caused by stress. Like all pressure sensors, these readings are converted into voltage or electrical signals that vary with the applied pressure intensity.

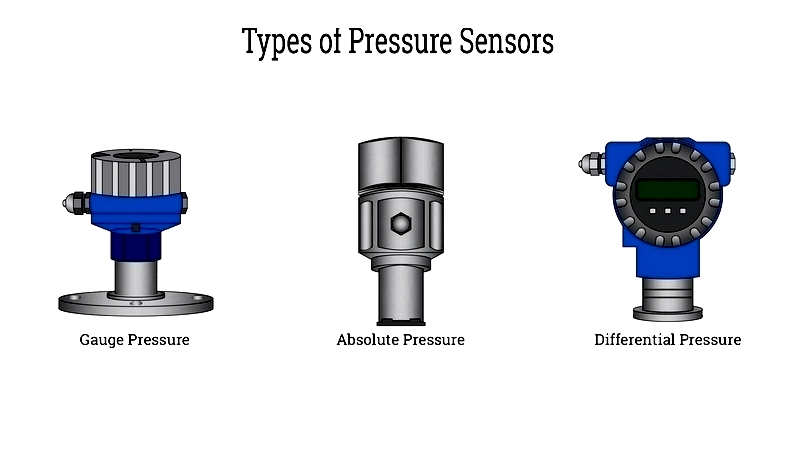

Pressure sensors are classified by their measurement range, temperature range, or pressure type. The main categories include absolute, gauge, sealed gauge, and differential pressure. Gauge pressure readings compare against fixed, chamber, atmospheric, or differential pressures.

Similar devices include pressure transducers, indicators, and transmitters. While all serve the same basic function, they differ in output signals. Pressure sensors produce signals relative to pressure strength, transducers convert force to voltage, transmitters output current in milliamps (mA), and indicators display pressure in psi.

Chapter 2: Types of Pressure Measurement

Pressure sensors alert operators to potential risks before system failures occur, allowing corrective action. Various types serve industrial and medical applications, helping users select the most suitable option.

With numerous sensor types available, choosing the right one can be challenging. Manufacturers assist customers with guidance, documentation, and expertise. Common types include aneroid barometers, manometers, bourdon tubes, vacuum (Pirani) sensors, sealed sensors, piezoelectric sensors, and strain gauges.

These devices are crucial for manufacturing, controlling gas/fluid flow, measuring speed, altitude, and water levels. Their diverse applications have led to variations in technology, design, performance, durability, and cost.

Pressure monitoring measures force exerted by gases or liquids on surfaces. Specialized sensors provide real-time data to predict potential failures.

Understanding pressure measurement types is essential. The main categories are absolute, gauge, differential, vacuum, and compound pressure, distinguished by their reference points.

Absolute Pressure

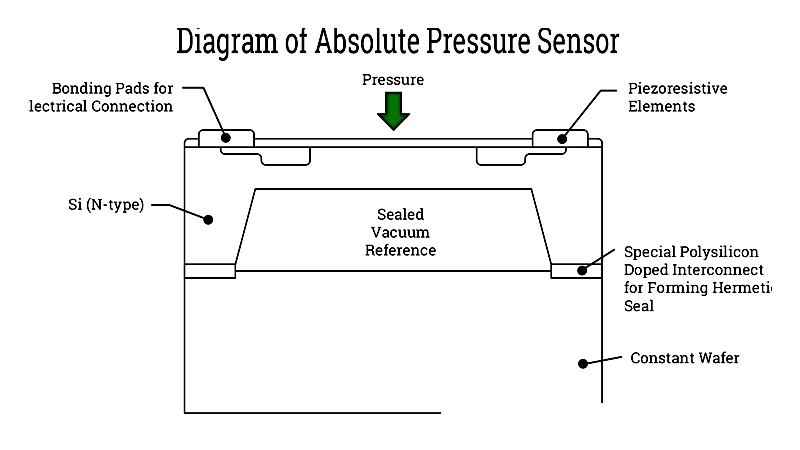

Absolute pressure measurements compare target pressure against a perfect vacuum reference. Boyle's Law explains that gas pressure inversely relates to volume at constant temperature, making these measurements temperature-dependent.

These measurements remain unaffected by atmospheric conditions, weather, or altitude, denoted as Pabs. Barometric pressure exemplifies absolute measurement, requiring a vacuum-sealed sensing diaphragm.

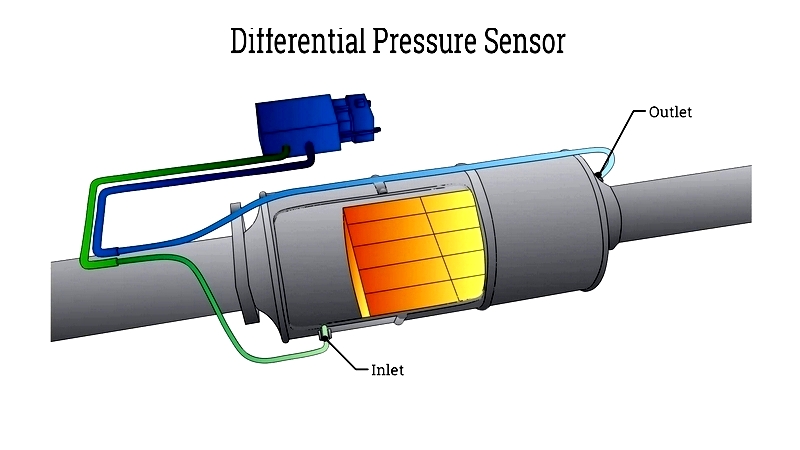

Differential Pressure

These sensors compare two system points, such as before and after a closed valve. Their purpose is detecting malfunctions rather than measuring absolute pressure, using two ports to measure diaphragm deflection on either side. Unaffected by atmospheric conditions, they're commonly used for filter protection.

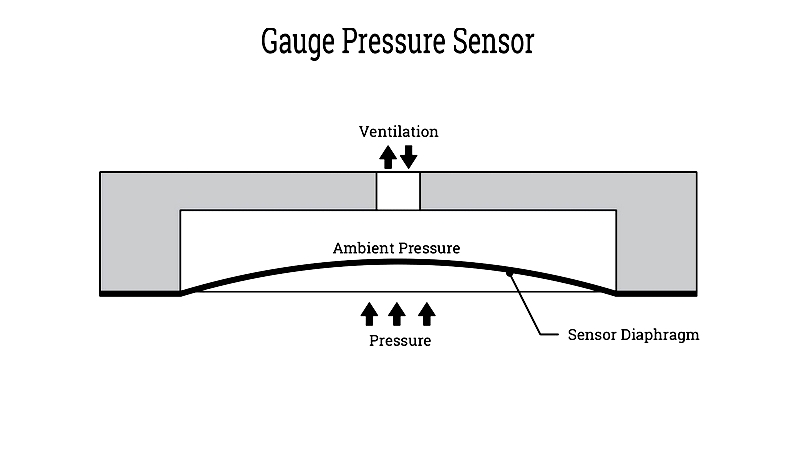

Gauge Pressure

Gauge pressure measures system pressure above atmospheric, with zero referencing ambient air. Readings vary with altitude and weather, relating to absolute pressure through the formula: Gauge = Absolute - Atmospheric.

Overpressure appears as positive (absolute > atmospheric) or negative (absolute < atmospheric), measured in psi.

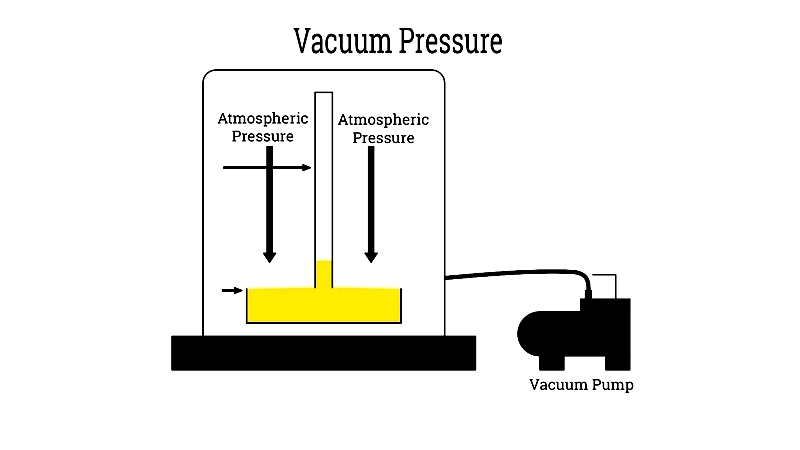

Vacuum Pressure

Measuring below atmospheric pressure, vacuum sensors examine force in low-pressure environments. Despite their accuracy, manufacturing challenges exist due to vacuum creation difficulties. Measurements appear negative relative to atmospheric pressure, using units like torr, Pascal, Bar, or atm.

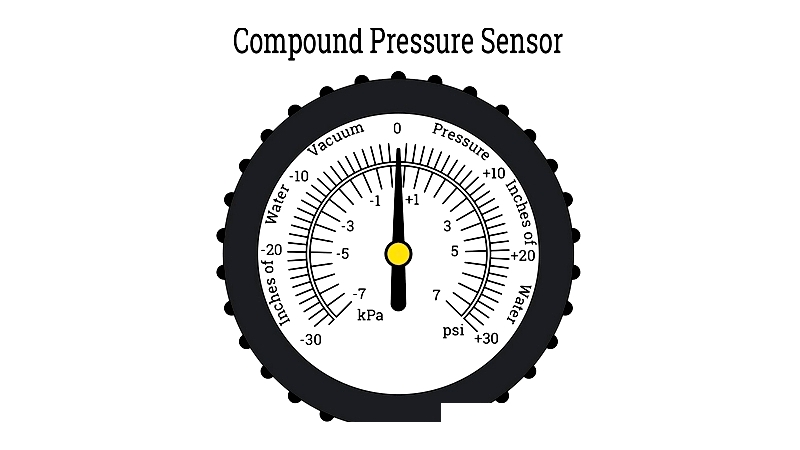

Compound Pressure

These sensors measure both positive and vacuum pressures, combining gauge and vacuum technologies. Their dials display positive and negative values with zero indicating atmospheric pressure. Using incorrect sensors for compound applications can cause permanent damage.

Pressure Measurement

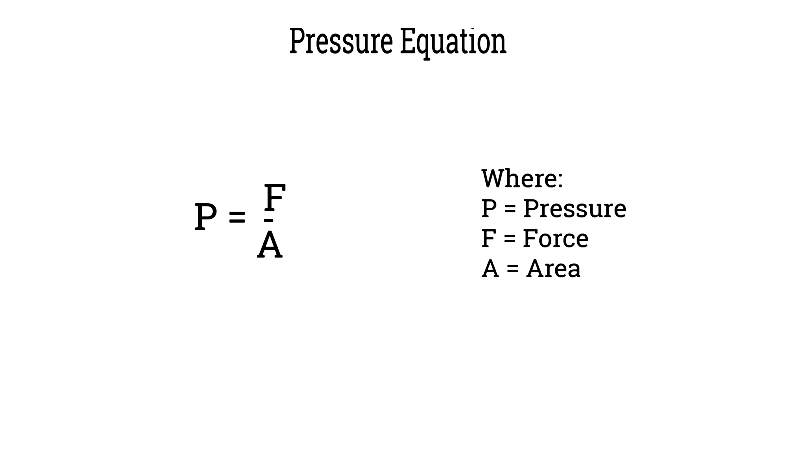

Experts understand pressure's critical role in equipment and personnel safety. Defined as force per unit area applied by various media, it's measured as absolute, gauge, or differential.

Before modern sensors, pressure was measured using liquid-filled manometers. The SI unit is pascal (Pa), with other units including psi, torr, and bar.

- Pounds Per Square Inch (psi): Measures force per square inch, commonly used in the US for gases, liquids, and material strength.

- Bar: Metric unit where 1 bar approximates atmospheric pressure (100,000 Pa), widely used in Europe.

- Torr: Non-SI unit equal to 1/760 of atmospheric pressure, originally used with mercury barometers.

While experts typically understand measurement units, basic knowledge helps when working with manufacturers. US companies use psi, bar, or mbar, while international standards prefer pascal or N/m². Other units include atm, in. Hg, mmHg, and torr, with selection depending on instrument type, application, industry, and regional preferences.