Introduction

This article provides comprehensive information about dumpers.

Readers will gain a clear understanding of:

- What dumpers are

- The types, applications, advantages, and disadvantages of dumpers

Chapter 1: What defines a dumper?

Dumpers are specialized machines featuring tiltable or hinged rear sections for easy unloading. This section explores various dumper types and their applications across multiple industries.

Chapter 2: What are the different types of dumpers?

This chapter examines various dumper types and their industrial applications, highlighting key differences in design, capacity, functionality, and safety features. Understanding these variations helps businesses select appropriate equipment for efficient material handling, workflow optimization, and workplace safety compliance.

Tote Dumpers

Tote dumpers are material handling devices designed to lift and tip large containers—such as totes, bins, or carts—for safe and precise unloading in industrial settings. Also known as bin dumpers or bulk container dumpers, they're commonly used in food processing, manufacturing, waste management, agriculture, and packaging operations.

Figure Provided by PPM-Tech

Figure Provided by PPM-TechTote dumpers offer significant ergonomic benefits in hygienic environments like food processing plants, where workers frequently transfer heavy materials. Even with team lifting, repetitive handling poses workplace hazards—including musculoskeletal disorders and repetitive strain injuries—increasing operational costs and compliance concerns.

Tote Dumpers and Ergonomics for Bulk Materials

Container handling, even with lighter loads, significantly increases injury risks. OSHA recommends limiting single-person lifts to 50 pounds or less. Grain handling often involves twisting motions that can cause muscular injuries.

Hydraulic tote dumpers substantially reduce manual lifting injuries. Compared to forklifts or manual methods, tote dumpers demonstrate superior efficiency, reliability, and safety.

Tote dumpers streamline the dumping process while enhancing operator safety and hygiene—particularly in regulated industries like food production, pharmaceuticals, and chemical processing. Capable of handling 1,000-5,000 pound loads, they're essential for high-volume production lines.

Unlike alternative methods, tote dumpers provide consistent, efficient, and safer container emptying. Hydraulic dumpers streamline production workflows and can be customized for stationary or mobile applications.

Stainless steel construction is preferred for sanitary tote dumpers due to its non-porous, easy-to-clean surface that withstands rigorous washdowns and meets FDA food contact regulations. These dumpers comply with 2017 FDA Food Code and modern food safety standards.

Container Dumpers

Container dumpers are heavy-duty machines for unloading materials onto conveyors, processing lines, or waste equipment. Versatile and essential for modern material handling systems, they serve recycling, mail processing, waste transfer, agriculture, and manufacturing industries. Customizable features enable handling of various materials—including packaged goods, loose materials, and liquids—to meet specific workflow needs.

Three primary container dumper categories address different operational requirements:

- Standard dumpers

- Heavy duty dumpers

- High reach dumpers

Standard Dumpers

The standard dumper series maximizes space efficiency. Suitable for medium-duty applications (up to six cycles hourly), these hydraulic dumpers feature compact designs with front-mounted cylinders and space-saving power units.

Heavy Duty Dumpers

Heavy duty container dumpers feature angled cylinders for enhanced mechanical advantage. With larger power units supporting higher cycle rates and heavier loads, they're ideal for demanding applications in recycling facilities and high-volume production lines.

High Reach Dumpers

High reach dumpers elevate dumping carriages before unloading. Built with heavy-duty construction, they're essential for feeding tall hoppers or elevated conveyors requiring overhead bin dumping.

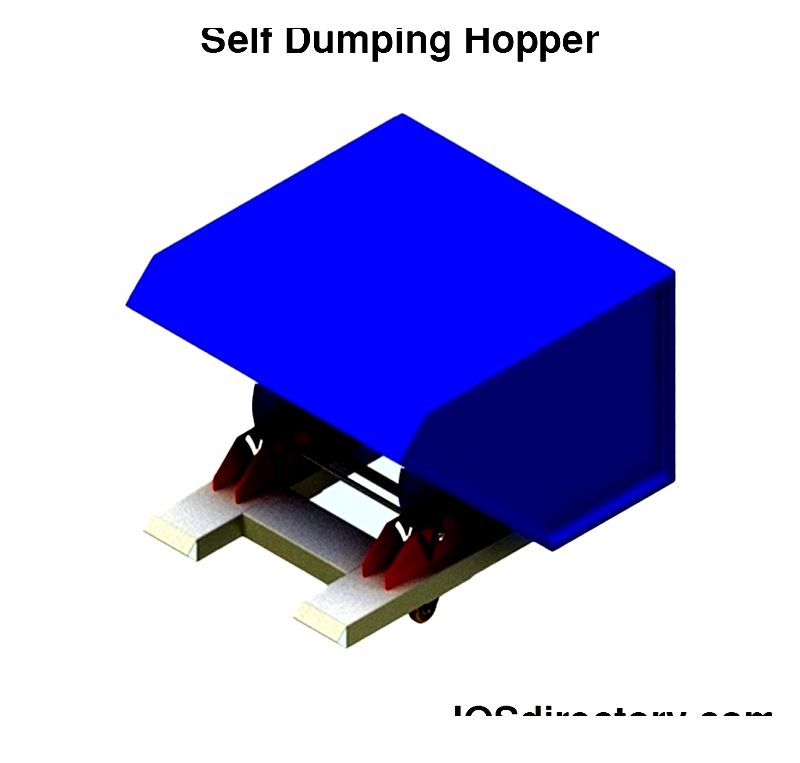

Self-Dumping Hoppers

Also called forklift dumpsters, self-dumping hoppers automatically dispose of collected waste using forklifts or pallet jacks. Widely used in manufacturing and industrial facilities, they efficiently handle scrap metal, wood waste, and general refuse.

Advantages of Self-Dumping Hoppers

These hoppers enable forklift operation without external lifts, motors, or pulleys. Automatic release latches and dump-from-seat controls enhance safety, reduce manual labor, and help maintain OSHA ergonomic compliance.

Commonly known as scrap hoppers, they're designed for waste handling. The dump-from-seat feature minimizes manual handling for improved operator safety.

Benefits of Self-Dumping Hoppers

- Increased efficiency—move large waste volumes in single trips

- Improved material handling—supports lean manufacturing principles

- Versatile applications—handle bulk materials, recyclables, or awkward items

- Enhanced safety—reduces lifting injuries and accident risks

Typical Applications

- Manufacturing plants

- Woodworking shops

- Construction sites

- metalworking facilities

- Recycling centers

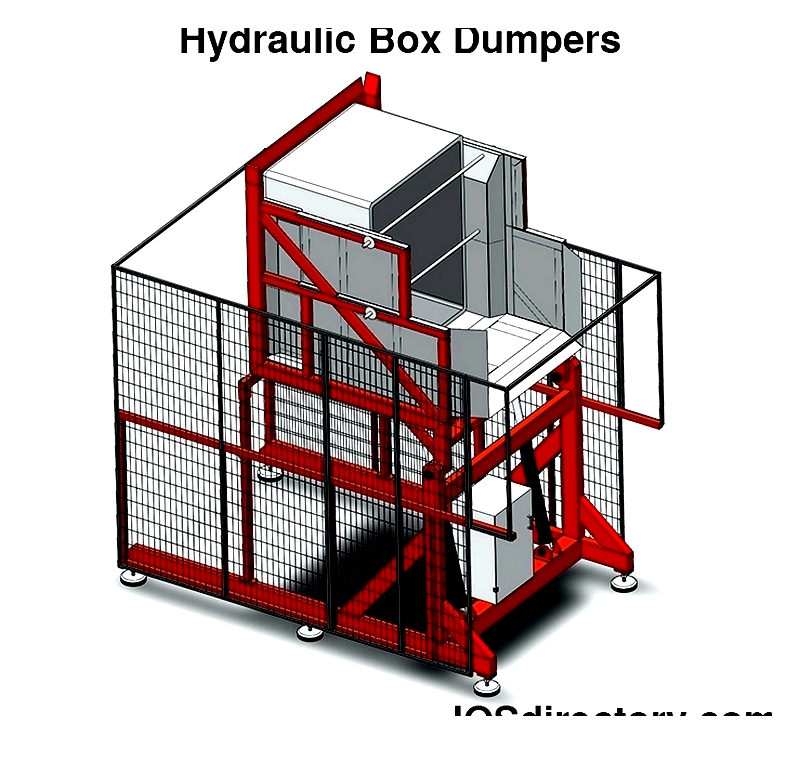

Box Dumpers

Box dumpers (or Gaylord box dumpers) accelerate material unloading while reducing operator fatigue and injury risks in warehouses and distribution centers. They efficiently transfer raw materials or finished goods into production or packaging lines.

Hydraulic Box Dumpers

Hydraulic models tilt and discharge large boxes or Gaylord containers. Portable floor-level units handle 60-95 gallon containers, with advanced models featuring PLC controls and automated safety systems.

Key Applications

- Conveyor feeding

- Material sorting

- Production equipment loading

- Recycling system integration

Industries Using Box Dumpers

- Food processing

- Warehousing

- Packaging

- Recycling

Operating Principle

Operators position containers on the platform and activate lifting/tilting via controls for fast, dust-free unloading.

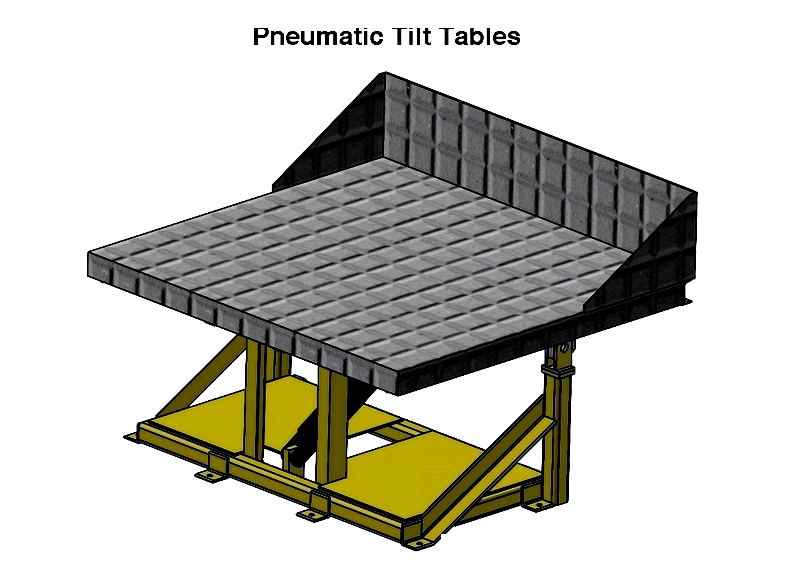

Tilt Tables

Tilt tables optimize ergonomics and safety for package handling and assembly tasks. They position heavy loads at ideal working heights/angles, reducing repetitive motion injuries and boosting productivity.

Common in industrial automation, tilt tables (including hydraulic and pneumatic models) support palletizing, assembly, and sorting operations. Chrome shafts and precision bearings ensure durability and minimize maintenance.

Types of Tilt Tables

Pneumatic models adjust tilt angles using compressed air for precise positioning. Manual/powered combinations allow single-operator load repositioning in warehouse settings.

Lift dumpers achieve greater heights than standard models. Hydraulic versions use robust cylinders for 10-foot+ discharges—essential for tall process vessels.

High Lift Dumpers

High-lift models feature dual cylinders and synchronized sprockets for 20-foot+ discharges, suitable