Introduction:

This article provides comprehensive insights into prefabricated buildings. Continue reading to explore:

- An Overview of Prefabricated Buildings

- Benefits of Prefabricated Construction

- Risks and Challenges of Prefabrication

- Types of Prefabricated Constructions

- And much more…

Chapter One – Overview of Prefabricated Buildings

Prefabricated buildings, commonly called prefabs, are constructed using factory-made components such as walls, roofs, and floors. These elements may be fully or partially assembled before being transported to the construction site. This method is favored for its cost efficiency, rapid construction, and recyclability. Prefabricated buildings are widely used for temporary worksites, offices, healthcare facilities, emergency shelters, schools, apartments, and single-family homes.

Compared to traditional construction, prefabrication offers greater efficiency due to its controlled manufacturing environment. Since many structures feature repetitive elements like walls and roofs, streamlined production processes can be established, allowing for continuous improvements in manufacturing techniques.

The concept of prefabricated structures traces back to ancient nomadic societies needing portable shelters. During colonization, demand for movable housing existed but declined as permanent settlements emerged.

Significant advancements in prefabricated building methods occurred in the 20th century, particularly during and after the world wars. Labor shortages during wartime led to housing scarcities, driving innovation in construction solutions.

Prefabricated buildings must meet the same standards as traditional structures, though regulations vary by region. In the U.S., modular buildings must comply with the International Building Code, which is regularly updated but differs across locations.

Before installation, site inspections assess soil conditions for foundation suitability. Third-party reviews ensure compliance with local, state, and international codes. once met, modular firms obtain necessary permits for construction and occupancy.

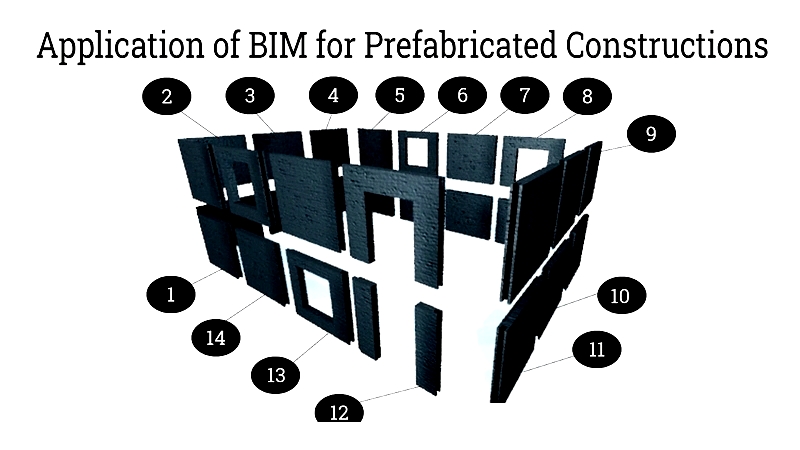

With evolving construction standards and increasing demand for housing and offices, prefabricated buildings remain viable alternatives. Technologies like Building Information Modeling (BIM) enhance assembly management and mitigate risks associated with prefabrication.

Chapter Two – Benefits of Prefabricated Buildings

Prefabricated buildings, also known as modular or pre-engineered structures, offer numerous advantages to manufacturers, contractors, architects, developers, and end-users. By splitting construction between on-site assembly and off-site fabrication, project schedules and costs become more manageable with effective project management. Off-site fabrication benefits from optimized assembly lines, automation, and standardized processes. The growing emphasis on sustainability presents opportunities for prefabricated buildings, especially with rising demand for green construction. Residential, commercial, industrial, and educational sectors are expected to adopt more modular solutions due to their innovation, adaptability, and cost-effectiveness.

Faster On-site Construction

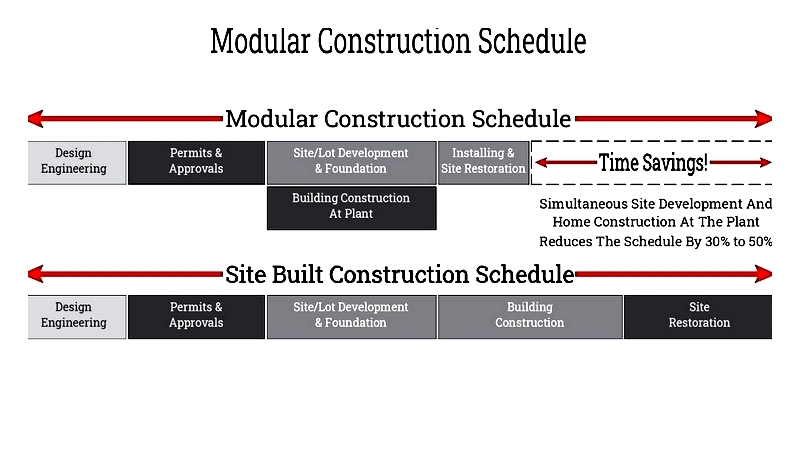

Manufacturing buildings in controlled environments significantly accelerates construction timelines. Workers in modular facilities perform repetitive tasks efficiently, aided by automation and robotics. Prefabrication allows simultaneous off-site activities like structural fabrication and utility integration while site preparation occurs. Buildings can arrive 90% complete, enabling rapid assembly. This speed benefits offices, healthcare units, classrooms, and temporary housing, minimizing disruptions.

Resistance to Uncontrollable Factors

Weather significantly impacts traditional construction, causing delays and safety risks. Prefabrication minimizes these effects since 90% of work occurs indoors. Climate-controlled manufacturing ensures uninterrupted progress regardless of external conditions. This reliability is crucial for sectors like healthcare and education.

Prefabrication reduces environmental impacts through controlled production of structural components. Techniques like shop welding and steel frame assembly are less affected by weather or site variability.

Higher Quality and Consistency

Prefabrication ensures superior quality through rigorous inspections and standardized processes. Dedicated quality control teams and building code officials review components at every stage. Experienced staff in modular plants enhance build quality and reduce errors, unlike traditional construction with variable labor skills.

Standardized components in prefabrication ensure uniformity across projects. This consistency is vital for industries requiring strict compliance, such as healthcare and pharmaceuticals.

Time Savings, Project Efficiency, and Cost Control

Prefabrication often matches or slightly exceeds traditional construction costs but offers greater efficiency and predictable timelines. Projects can be completed in half the time, reducing overhead and operational downtime. Precision engineering and customizable features make modular construction ideal for offices, schools, and cleanrooms.

Flexibility, Reusability, and Disassembly

Many prefabricated buildings are designed for temporary or semi-permanent use, such as classrooms, healthcare units, or disaster relief housing. They can be disassembled and relocated, minimizing site disruption and environmental impact.

Environmentally Friendly Materials and Sustainability

Prefabrication supports sustainability through efficient material use and waste reduction. Leftover materials are often recycled, reducing landfill waste. Energy-efficient designs with optimal insulation and renewable energy compatibility further enhance environmental benefits.

Improved Worker Safety and Reduced On-Site Hazards

Off-site fabrication provides safer working conditions by minimizing exposure to heights, weather, and hazardous materials. Ergonomically designed workstations and safety compliance reduce injury rates.

Performance and Lifespan Inspection

Prefabricated buildings typically last 30+ years with proper maintenance. Continuous inspections during production ensure quality and durability, offering long-term value for owners.

When selecting prefabricated solutions, choose reputable suppliers with proven expertise in delivering code-compliant, customizable structures that meet your specific needs.