Introduction

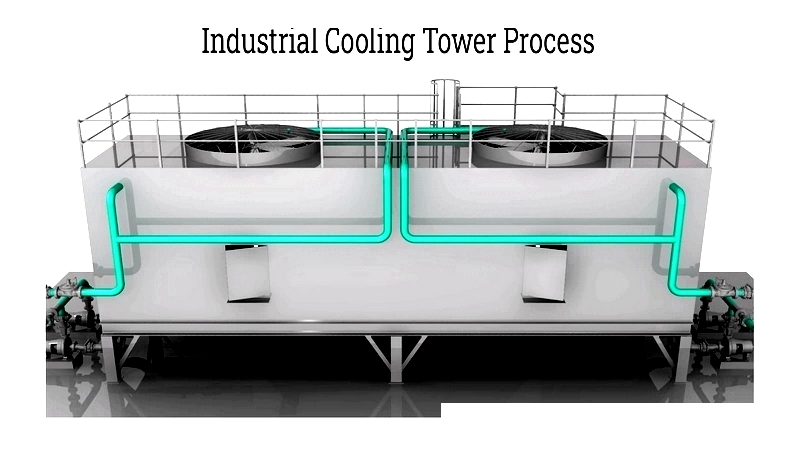

This article provides an in-depth examination of Open Loop and Closed Loop Cooling Towers.

It covers key topics including:

- Operation principles of Open Loop and Closed Loop Cooling Towers

- Components and functions of both tower types

- Different varieties of Open Loop and Closed Loop Cooling Towers

- Applications and advantages of each system

- Additional relevant information

Chapter 1: Operating Principles of Open Loop and Closed Loop Cooling Towers

This section examines the working mechanisms of both cooling tower systems.

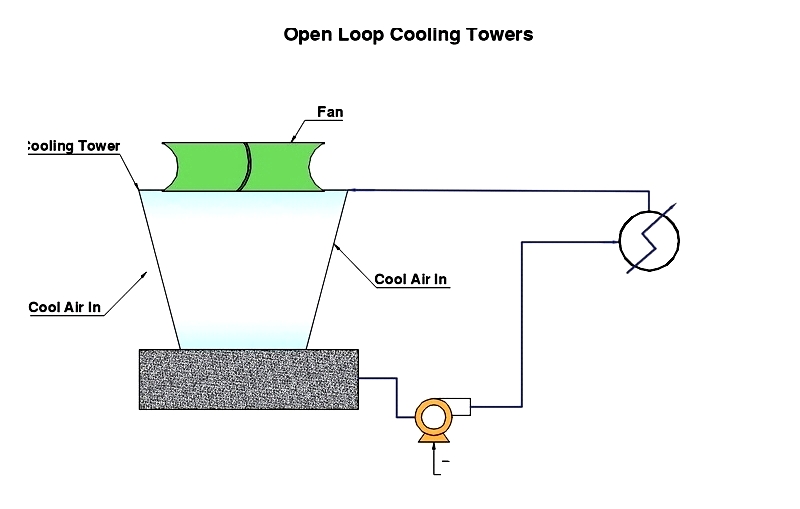

An open loop cooling tower directly exposes the process water to ambient air for heat dissipation.

Open loop systems achieve cooling through direct air-water contact, functioning as heat exchangers that transfer heat partially through air-water exchange. Evaporation of a small water portion enables cooling below ambient temperatures.

Open Loop Cooling Tower Operation

Water enters at the tower top and distributes evenly across packing material via nozzles, forming a thin film that maximizes surface area for efficient heat transfer.

Fans circulate air through the packing, cooling water through convection and evaporation. The moist air exits at the top while cooled water collects in a basin for reuse. Drop eliminators prevent water droplet escape.

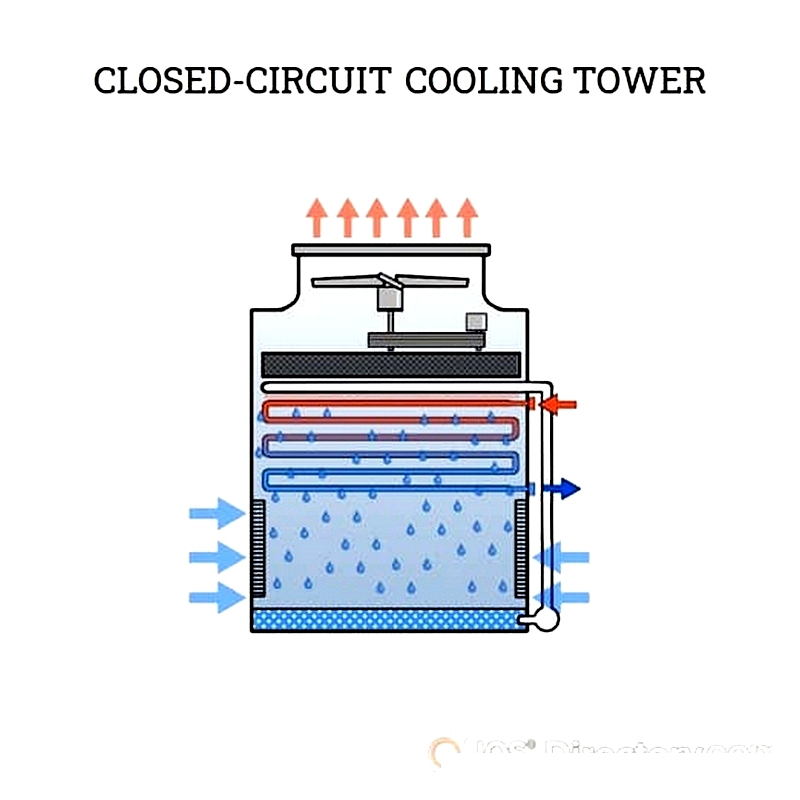

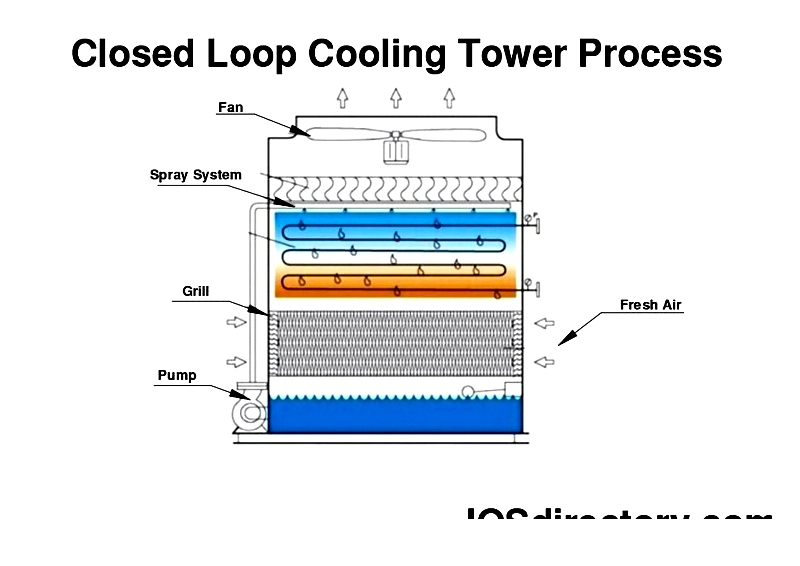

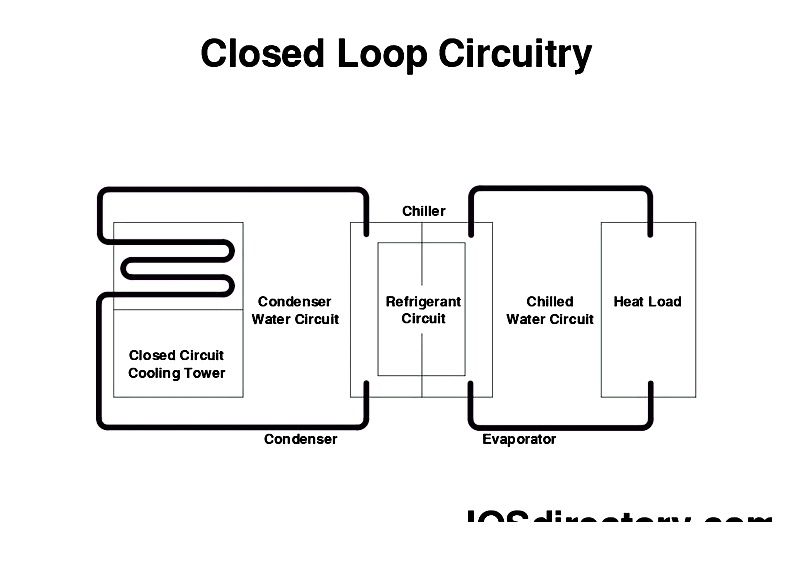

Closed Loop Cooling Towers

These systems maintain complete separation between process water and cooling air, operating within a closed circuit.

Closed loop systems employ additional heat exchangers for thermal transfer, sometimes incorporating piping and plate heat exchangers.

Closed Loop Operation

When direct water-air contact is undesirable (e.g., food processing), heat exchangers isolate process water from evaporation water. Closed systems may require antifreeze, unlike open loop towers.

Process Side

Process water circulates through stainless-steel plate heat exchangers, transferring heat to cooling water before reuse in a closed circuit serving various equipment.

Tower Side

Heated water from the exchanger flows to the tower top, spreads over packing, cools as it descends, and collects in a basin for recirculation. Countercurrent airflow absorbs heat before exiting at the top, with drop eliminators preventing water loss.

Performance Factors

Several variables affect cooling tower efficiency:

Temperature Range

The difference between incoming and outgoing water temperatures. Larger ranges can reduce capital and operating costs.

Heat Load

Determined by process requirements, heat load affects tower sizing. Precise measurement varies by application type.

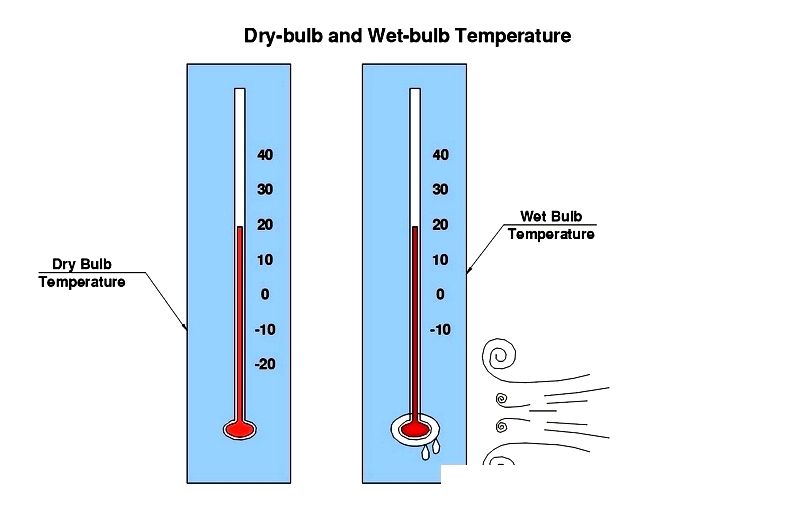

Wet-bulb Temperature (WBT)

Measured with a moistened thermometer, WBT indicates local humidity conditions when compared to dry-bulb readings. Cooling towers cannot cool below this critical parameter.

Proper WBT measurement requires careful tower placement away from heat sources.

Temperature Approach

The difference between exit water temperature and incoming air WBT. This key performance metric typically ranges 5-20°F, with lower approaches requiring exponentially larger towers.

Performance Calculations

Approach = CWT - WBT

Range = HWT - CWT

Efficiency = (Range / (Range + Approach)) × 100

Chapter 2: Components and Functions of Cooling Towers

This section details the structural elements and operational roles of cooling tower components.

Instrumentation

Typical systems include blowdown rate controls, flow meters, level switches, vibration monitors, thermocouples, and oil level indicators.

Fan Motors

Explosion-proof motors with protective relays are essential in hazardous environments like refineries.

Nozzles

Plastic nozzles (polypropylene, ABS, PVC) ensure uniform water distribution across tower cells.

Distribution Valves

Corrosion-resistant valves regulate water flow for even cell distribution.

Drive Systems

Shafts transmit motor power to gear reducers, which adjust speed to operational requirements.

Louvers

Asbestos louvers prevent water loss and optimize airflow through fill media.

Structural Components

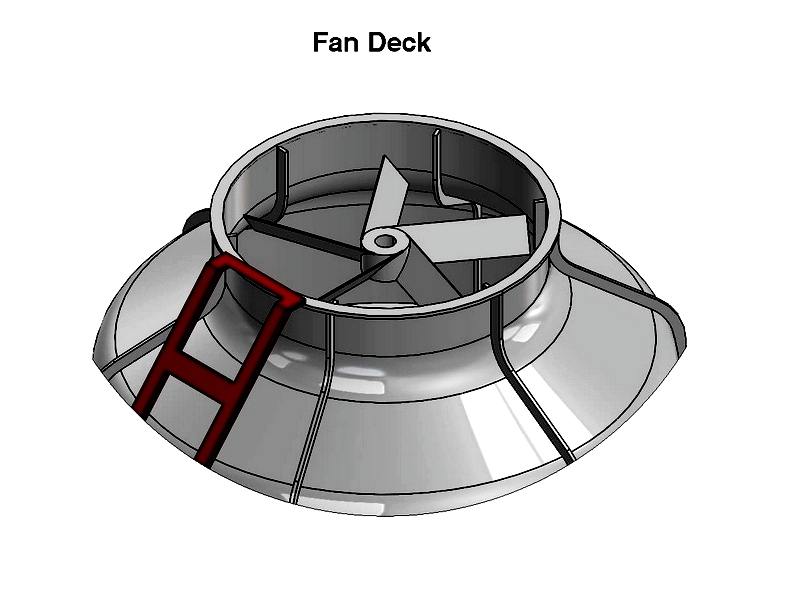

Fan decks support cylinders and provide maintenance access to distribution systems.

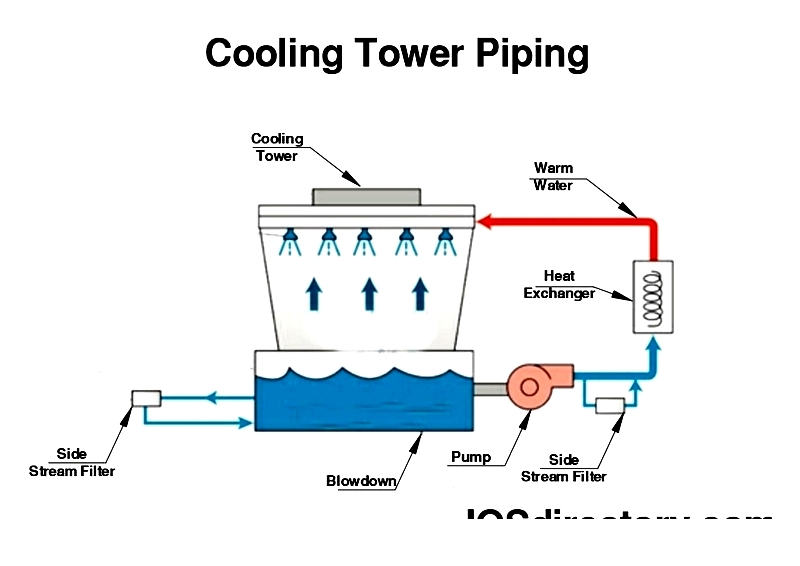

Piping

Properly supported or buried piping prevents thrust loading on tower structures.

Fans

FRP, aluminum, or steel fans with adjustable blade angles optimize seasonal performance.

Construction Materials

Treated wood, FRP, or concrete structures selected based on application requirements.

Water Basins

RCC basins collect cooled water and support tower structures, with height measured from basin to fan.

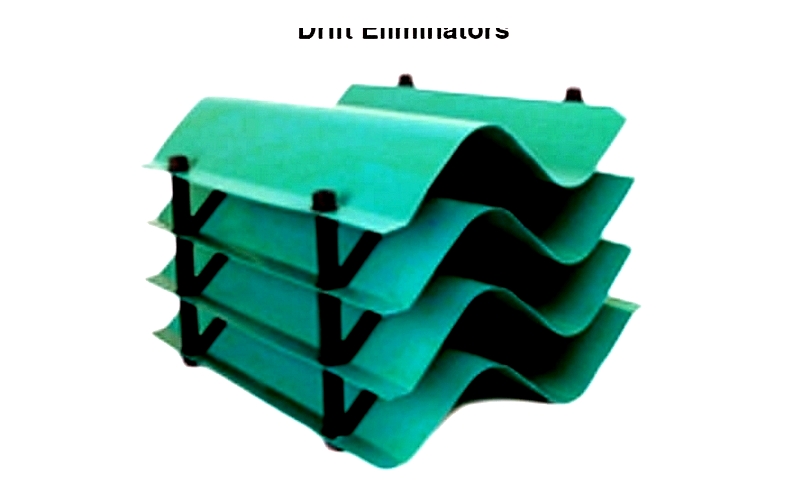

Drift Eliminators

PVC devices minimize water loss by redirecting airflow, though with increased pressure drop.

Fill Media

Polypropylene, wood, or PVC media maximize air-water contact through vertical, cross-corrugated, or offset configurations.