Introduction

This article provides a comprehensive guide to blister packaging. You'll discover:

- Advantages of Blister Packaging

- Blister Packaging Operation

- Components of a Blister Pack

- Methods of Blister Foil Forming

- And much more…

Chapter One – Understanding Blister Packaging

Blister packaging, commonly called blister packs, consists of pre-formed plastic cavities with flexible coverings. Products are placed in these molded pockets and sealed with lidding material, typically through heat bonding. Available in various formats, blister packaging is widely used in pharmaceuticals for pills, tablets, capsules, and lozenges. Its cost-effectiveness, due to inexpensive materials and efficient production, also makes it popular for consumer goods like food, electronics, toys, and tools. Key benefits include:

Advantages of Blister Packaging

Individual Packaging

Originally developed for birth control pills, blister packs offer an economical way to package single medication doses. Their clear dosing indicators help ensure proper administration. Each dose is isolated in individual pockets, maintaining quality while preventing cross-contamination if one section is damaged.

Maintaining Product Integrity

Blister packaging materials are selected based on product sensitivity to light, oxygen, and moisture. Barrier layers can be added to protect contents from contaminants. For example, opaque aluminum materials shield products from UV degradation.

Tamper Protection

Blister packs feature tamper-evident designs since opened packaging cannot be resealed. Visible damage remains when lids are removed from blister cards, deterring tampering and theft in pharmaceuticals and consumer goods.

Preventing Accidental Drug Misuse

Child-resistant (CR) packaging designs require specific actions to open, reducing accidental ingestion risks for children and seniors.

Product Visibility

Blister packs showcase products clearly for retail display, with eye-catching colored lids or backing materials.

Secure Product Fit

Using CAD software, blister molds are precision-engineered to match product shapes with minimal clearance.

Contract Packaging

Many manufacturers outsource packaging to specialized providers offering labor, equipment, and regulatory-compliant solutions. Contract packaging companies handle quality testing, graphic design, manuals, inventory, and distribution, allowing manufacturers to focus on production.

Chapter Two – The Blister Packaging Process

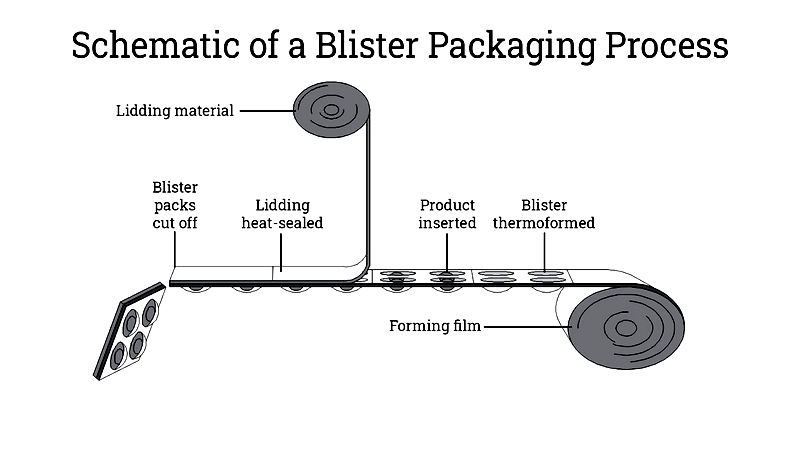

Essential for pharmaceuticals, electronics, and retail, blister packaging protects products while ensuring tamper evidence and shelf life. The process begins with design collaboration between engineers and manufacturers to select optimal materials. A custom negative die is CNC-machined from metal stock to create cavity molds for thermoformed or cold formed packaging.

Thermoforming heats PVC, PET, or PETG films to stretch over dies using vacuum and air pressure. Cold forming mechanically presses aluminum foil into molds for moisture- and light-sensitive products.

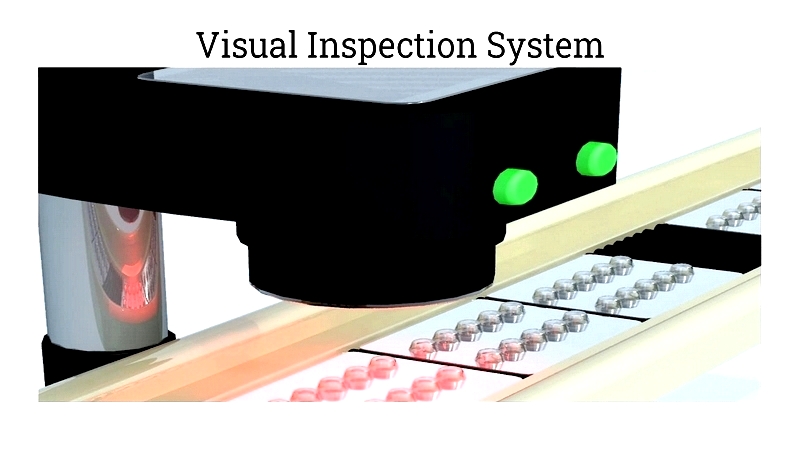

Products undergo visual and automated inspections before being loaded into blister cavities. High-volume systems use vibratory feeders for precise placement.

Advanced inspection systems detect defects before sealing, where lidding materials are heat-bonded to blister sheets. Cooling stabilizes seals before die-cutting creates individual cards with features like tamper-proofing or child-resistant mechanisms.

Quality tests include dye leak detection and modern methods like laser inspections. Compliance with FDA, cGMP, and ISO standards ensures product safety and brand trust.

By integrating advanced materials, automation, and quality control, blister packaging delivers secure, cost-effective solutions across industries. Partnering with experienced providers helps businesses achieve optimal protection, compliance, and customer satisfaction.