Introduction

This article provides comprehensive information about brass metal.

It covers the following topics:

- What is brass metal?

- Types of brass alloys

- Applications of brass metal

- Brass rolls

- Brass angle and solid brass

- Brass sheet metal and its applications

Chapter 1: Understanding Brass metal

Brass refers to a group of copper-zinc alloys known for their durability, strength, and corrosion resistance. Adjusting the copper-to-zinc ratio modifies brass's mechanical properties, corrosion resistance, and thermal characteristics for different applications. Typically, brass contains 60% to over 80% copper, with zinc making up less than 10% to more than 40% of the composition.

Brass alloys with over 30% zinc are classified as high brass. This type is less malleable, more brittle, and harder to form. Higher zinc content can increase brass's susceptibility to corrosion as zinc reacts with air and water to form a zinc oxide layer.

Brass containing more than 85% copper is called red brass or gunmetal, prized for its excellent malleability, ductility, corrosion resistance, and ease of shaping. It's highly machinable, facilitating processes like cutting, forming, and drilling. However, its high copper content also makes red brass more expensive.

Advantages of Adding Lead to Brass

Lead is added to brass alloys with copper and zinc to act as a stabilizer, improving malleability and machinability. However, due to health risks associated with lead exposure, its content in brass is strictly regulated. Typically, lead levels must remain below 2%, with even stricter limits in some regions.

The Unified Numbering System (UNS) for metals and Alloys

The Unified Numbering System (UNS) assigns a unique code to each metal type, consisting of a letter and five digits. This identifier specifies chemical composition rather than mechanical properties. The first three digits derive from existing numbering systems.

For brass alloys, UNS codes begin with "C" followed by five digits. Classifications include C20000-C29999 for yellow brass, C30000-C39999 for leaded brass, C40000-C49999 for tin brass, and C87300-C87900 for cast silicon brass. Red brass, with 85% copper content, is designated C23000.

Properties of Brass Alloys

Zinc content affects brass's malleability. When zinc exceeds 45%, the alloy becomes difficult to work with. White brass, a coarse type, is used in brazing applications and die casting despite limited economic significance.

Brass varieties with under 40% zinc are pliable and suitable for cold working. Alpha brass, with less than 37% zinc, is named for its unique crystal structure, while alpha-beta brass (duplex brass) contains 37%-45% zinc and features both alpha and beta structures.

While copper and zinc are brass's primary components, other elements like lead may be added to enhance physical or mechanical properties and improve corrosion resistance. Naval brass, an alpha-beta type, contains 59% copper, 40% zinc, 1% tin, and trace lead, with tin boosting marine corrosion resistance.

Different brass types are identified by their crystal structures: face-centered cubic (FCC) or body-centered cubic (BCC). High-copper brass has an FCC structure similar to pure copper, while high-zinc brass adopts a BCC configuration.

Brass metal Characteristics

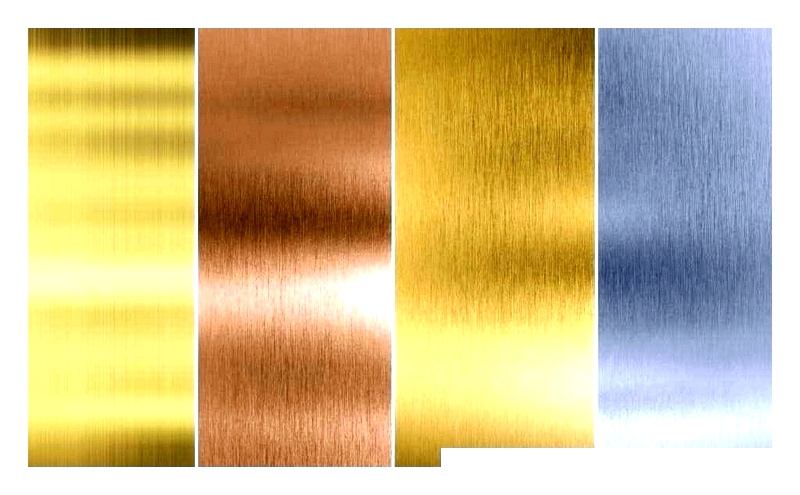

Brass exhibits various colors, including reddish-gold, silvery-white, or vibrant gold. Higher zinc content adds a silvery sheen, while more copper imparts a rose hue.

Compared to bronze and zinc, brass shows greater malleability.

- Brass is ideal for musical instruments due to its superior acoustic properties.

- It exhibits low friction.

- Brass is preferred when non-sparking metals are required.

- It has a relatively low melting point and conducts heat efficiently.

- Brass offers excellent corrosion resistance, even against saltwater-induced galvanic corrosion.

- It's easy to cast.

- Being non-magnetic, brass is simpler to recycle by separating from ferrous metals.

- As one of the most common metal alloys, brass appears in everyday items like doorknobs and jewelry.

- Beginners in metalworking should learn to work with brass due to its widespread industrial and commercial use. Reliable suppliers offer various brass alloys to meet diverse needs.

Chapter 2: Different Types of Brass Alloys

Brass alloys are crucial in metalworking, valued for their toughness, corrosion resistance, and versatile engineering properties. Each type's unique characteristics stem from its copper-to-zinc ratio and additional elements. Alloying additions like tin, aluminum, iron, lead, silicon, or bismuth fine-tune properties such as machinability, tensile strength, corrosion resistance, and workability. These features make brass alloys highly sought after in manufacturing, construction, marine, and electrical industries.

Understanding various brass types and their compositions is essential for selecting the right material. Brass is renowned for its malleability, conductivity, antimicrobial properties, and attractive appearance, making it ideal for plumbing, decorative fixtures, musical instruments, and precision components. Below are common brass alloy families and their typical uses.

Alpha Brasses - C26000

Alpha brass, or "cartridge brass," is a monophasic alloy with a yellowish tint. Despite potential vulnerability to certain conditions, it offers reliable performance with superior mechanical strength, high ductility, and excellent corrosion resistance, outperforming many other brass variants. This makes alpha brass preferred for forming processes in industrial and commercial manufacturing.

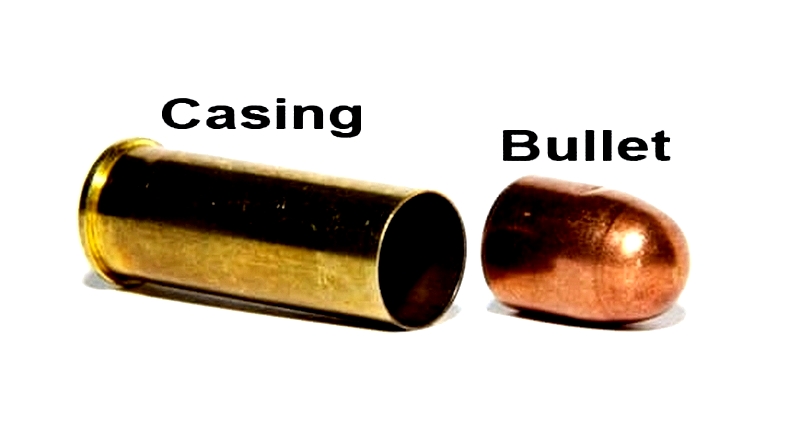

Cartridge brass (C26000), with its homogeneous alpha structure and under 37% zinc, is commonly used in ammunition cartridges, heat exchanger tubes, evaporators, automotive radiators, fire extinguishers, electrical socket springs, rivets, bolts, and screws. Its uniform composition ensures consistent performance in sheet metal fabrication, deep drawing, welding, rolling, and brazing. Often called 70/30 brass, it contains about 70% copper and 30% zinc, balancing strength, malleability, and electrical conductivity.

Alpha brasses excel in cold working, offering excellent formability for drawing and bending. Their resistance to dezincification makes them suitable for plumbing fittings and marine hardware. Their softness and adaptability also make them popular for fasteners and spring components, ensuring reliable performance in demanding environments.

Alpha-Beta Brass

Alpha-beta brasses, or "duplex brasses," contain 37%-45% zinc and feature both alpha and beta grain structures. The alpha-to-beta phase ratio depends on zinc content, with additional elements like aluminum, silicon, or tin enhancing beta-phase qualities to improve strength, corrosion resistance, and heat resistance.