Introduction

This comprehensive guide covers everything you need to know about plastic fabrication. You'll learn about key topics including:

- What plastic fabrication is

- Different plastic fabrication methods

- Finishing processes in plastic fabrication

- And much more...

Chapter 1: What is Plastic Fabrication?

Plastic fabrication involves the creation, production, and assembly of components using plastic materials or composites. With the vast array of plastic products available today, numerous fabrication techniques have been developed, each offering unique advantages for specific design needs. Manufacturers favor plastic fabrication for its cost-efficiency and versatility, making it suitable for diverse products across multiple industries.

Plastics are categorized into thermosetting plastics and thermoplastics, distinguished by their response to heat and pressure. Thermoplastics can be reshaped multiple times as their molecular structure allows repeated softening and reforming, unlike thermosets which become permanent after setting.

Thermoplastics further divide into crystalline and amorphous types, selected based on application requirements. Common crystalline resins include nylon, acetal, thermoplastic polyester, and polyethylenes, while amorphous resins comprise PVC, styrene, ABS, and polycarbonate. These materials can be melted, shaped, and joined through various fabrication processes.

Thermosetting plastics, once cured, cannot be remelted but can be machined and bonded. They include durable materials like phenolics, bakelite, G-10, and GPO polyesters, valued for their strength and suitability for structural and insulating applications.

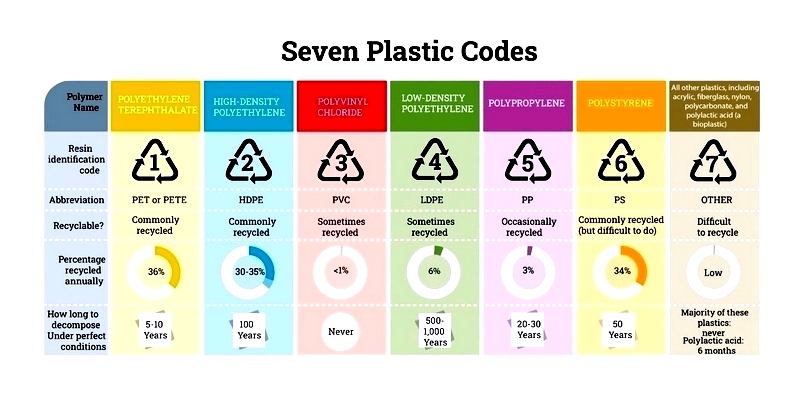

Both plastic types are classified into seven categories by molecular structure, indicated by recycling codes:

- Polyethylene Terephthalate (PETE) Fabrication - Produced through step-growth polymerization of ethylene glycol and terephthalic acid.

- High-Density Polyethylene (HDPE) Fabrication - Derived from petroleum with a linear crystalline structure offering exceptional versatility.

- Polyvinyl Chloride (PVC) Fabrication - Durable thermoplastic available in rigid and flexible (plasticized) forms.

- Low Density Polyethylene (LDPE) Fabrication - Petroleum-based with branched structure providing flexibility.

- Polypropylene (PP) Fabrication - Nonpolar, partially crystalline polyolefin, the world's second most produced plastic.

- Polystyrene (PS) Fabrication - Polymerized styrene, adaptable to expanded (EPS) and extruded (XPS) forms.

- Miscellaneous Types - Includes acrylics, nylon, polycarbonates, bioplastics, and multilayered composites.

Chapter 2: Plastic Fabrication Methods

The plastic fabrication industry employs diverse processes tailored to material properties and end-use requirements. Method selection directly impacts product performance, precision, and cost-effectiveness. Key techniques include:

- Plastic Welding

- Plastic Machining

- Compounding

- Plastic Lamination

- Molding (Injection, Compression, Blow, Rotational)

- Plastic Extrusion

- Thermoforming

- Die Cutting

- Pultrusion

- Forging

- Vacuum Casting

Plastic Welding

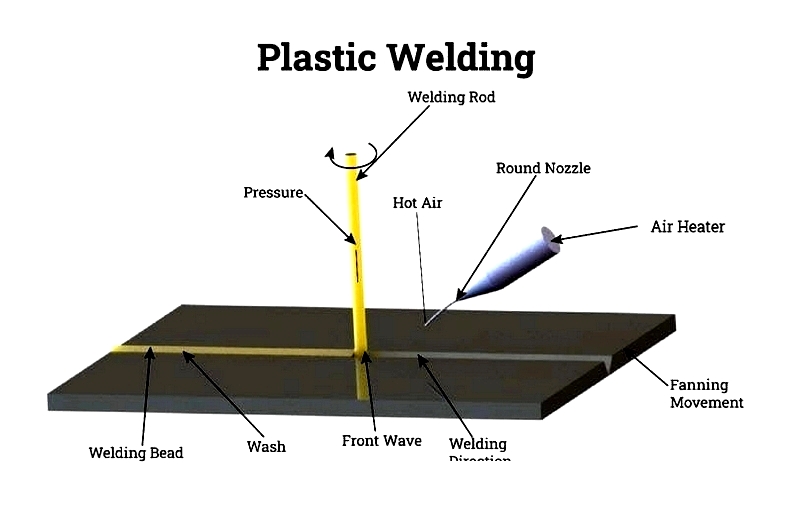

This fundamental technique melts workpieces to create molecular bonds through three stages: pressing, heating, and cooling. A filler rod (typically matching the workpiece material) is used after heating surfaces to melting point. Various methods exist including contact welding, ultrasonic welding, and hot gas welding, each with distinct advantages regarding speed, strength, or material compatibility.

Common applications include plumbing systems, automotive parts, and chemical storage tanks where leak-proof bonds are critical. Quality control ensures weld integrity for industries like pharmaceuticals and food processing.

Compounding

This process blends polymers with additives to create custom materials with specific mechanical, electrical, or thermal properties. The compound is then shaped using molds or extrusion tools. It's valuable for automotive, electronics, and medical sectors where precise material performance is essential.

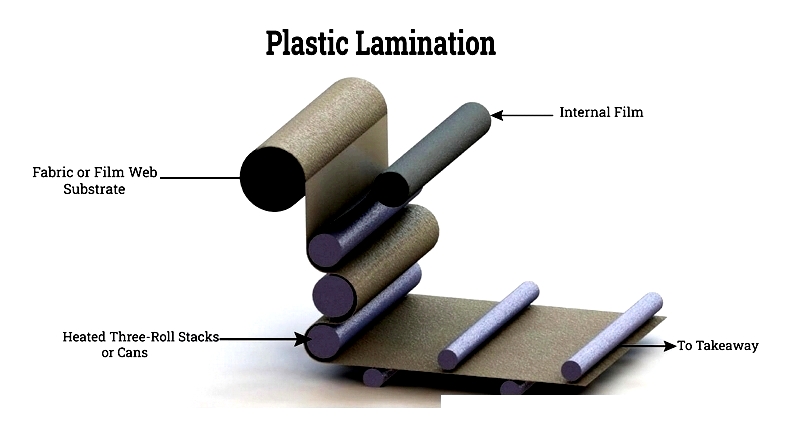

Plastic Lamination

Bonding plastic layers with other substrates enhances durability, appearance, and resistance. Two primary methods exist: film lamination (high-volume) and resin lamination (composite panels). Though time-intensive, it produces superior products for packaging and construction.

Plastic Molding

This widely-used process heats and shapes plastic resins in molds. It supports high-volume production of precise components.

Injection Molding

The most common method injects molten plastic under pressure into molds. Cost-effective for mass production of items from automotive parts to medical devices.

Compression Molding

Heats and compresses thermosetting plastics in molds, ideal for large, strong components like automotive parts.

Rotational Molding

Creates hollow products by rotating heated molds with plastic powder. Suitable for water tanks and outdoor furniture.

Blow Molding

Forms hollow items like bottles by inflating heated plastic tubes in molds. Fast and economical for containers.

Plastic Extrusion

Continuous process forcing melted plastic through dies to create profiles like pipes and window frames. Valued for construction and packaging applications.

Thermoforming

Heats and forms plastic sheets using molds and vacuum/pressure. Ideal for packaging and disposable products.

Die Cutting

Precision cutting of plastic sheets into custom shapes for electronics, medical, and packaging industries.

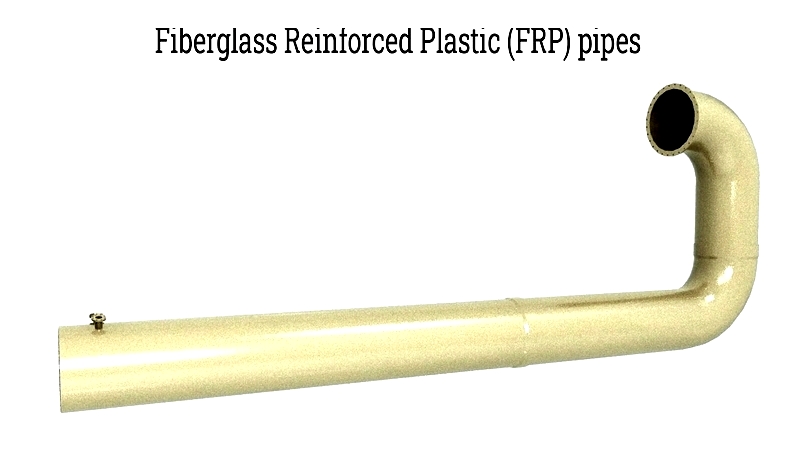

Pultrusion

Continuous process for reinforced plastic profiles with excellent strength and corrosion resistance.

Forging

Shapes plastics under force for enhanced strength in applications like automotive components.

Vacuum Casting

Creates detailed prototypes and low-volume parts without expensive tooling.

Summary: Each fabrication method offers unique benefits for specific materials and applications. Understanding these processes helps manufacturers select the optimal approach for cost-effective, high-quality plastic components.

Chapter 3: Plastic Fabrication Finishing Processes

Finishing determines final appearance, durability, and performance. Processes include:

Joining Processes

Plastic welding is common for large structures like PVC tanks. Methods include hot plate, ultrasonic, and RF welding.

Surface Finishing

Includes de-flashing, cleaning, and coating to enhance appearance and functionality. Critical for consumer products and medical