Introduction

This article provides an in-depth exploration of graphite machining.

You will discover key topics including:

- What graphite machining entails

- The graphite machining process

- Graphite production methods

- Applications of machined graphite parts

- And more…

Chapter One – What is Graphite Machining?

Graphite machining refers to the shaping, molding, configuring, and precision cutting of graphite materials to create various industrial parts and components. The success of graphite machining primarily depends on the tools used. Manufacturers employ specially designed cutting tools that reduce chipping and breakouts. Indexable carbide cutters are commonly used for their efficient design, making them ideal for high-speed roughing operations.

Graphite exists in two main forms: natural and synthetic. Natural graphite forms in igneous and metamorphic rocks and is mined globally. Synthetic graphite, on the other hand, is produced by heating carbon-rich materials like pitch, coal, and acetylene to extreme temperatures. This process rearranges carbon atoms into layered graphite structures.

Chapter Two – How Graphite is Machined?

Graphite machining shares similarities with precision machining techniques for materials like cast iron but presents unique challenges. Due to graphite's brittle, crystalline nature, machining produces fine powder-like chips called swarf. Unlike metal machining, specialized tools slice through graphite in a manner akin to plowing snow, yielding smooth edges and high-quality finishes ideal for EDM electrodes, semiconductor components, and carbon brushes.

Graphite's high compressive strength allows secure clamping during CNC machining. Determining the proper clamping force is crucial to prevent deformation or breakage. Gradual testing helps identify the optimal force for vibration-free, high-speed machining.

Methods For Graphite Machining

Specialized Tools

Tool selection is critical in graphite machining. Graphite's abrasive nature quickly wears down standard tools. Diamond-coated or polycrystalline diamond (PCD) tools are recommended for longevity. Tungsten carbide offers a viable alternative, while high-speed steel suits low-volume tasks. Proper tool selection and machining parameters minimize chipping and ensure dimensional accuracy.

Baking Graphite

Ensuring graphite is dry before machining protects tools and maintains precision. Moisture turns graphite dust into an abrasive slurry, accelerating tool wear. Graphite billets should undergo drying before processing. During manufacturing, temporary binders like pitch carbonize during baking, strengthening the material's structure. Additional high-temperature treatment enhances properties for demanding applications.

The importance of Ventilation

Effective dust control is essential when machining graphite. The fine, conductive dust can damage equipment and pose health risks. OSHA sets exposure limits at 15 mppcf or 1.5 mg/m³. Modern facilities use dust extraction systems and HEPA filters to maintain compliance and protect workers.

Climb Milling and Conventional Milling

Climb milling (down-milling) is preferred for graphite as it reduces chipping and tool wear. Efficient chip removal ensures quality when producing intricate components. High-speed CNC mills with dust protection deliver precision for both large and small batches.

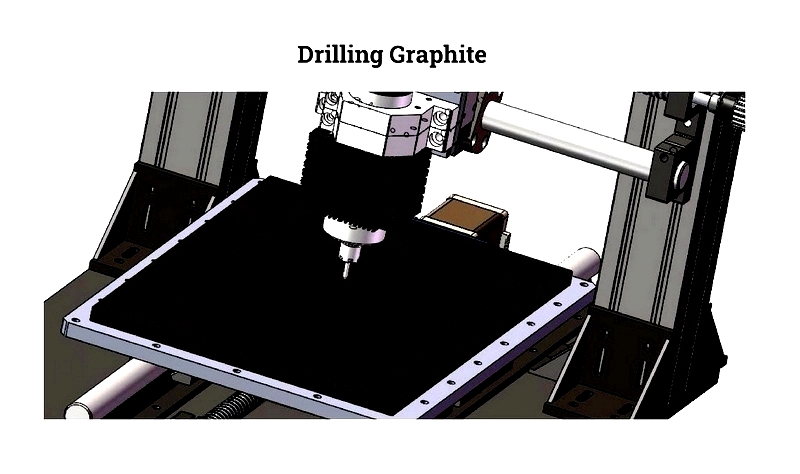

Drilling Graphite

Drilling requires careful dust management. Diamond-coated or carbide-tipped drills enable higher speeds while controlling heat. Graphite grade influences drilling parameters and cooling needs for consistent results.

Safety and Turning

Minimizing force during turning prevents damage. Collet chucks enable secure workpiece handling. Tool rigidity is crucial to prevent chatter and maintain surface quality for critical applications.

Sawing Graphite

Precision sawing demands effective dust collection. Tungsten carbide or diamond-grit blades extend tool life and ensure clean cuts, essential for industries requiring high purity.

Types of Machined Graphite Processes

Graphite can be processed through various methods, each suited to specific applications. Key processes include extrusion, isostatic pressing, vibration molding, and conventional molding.

Extruding Process

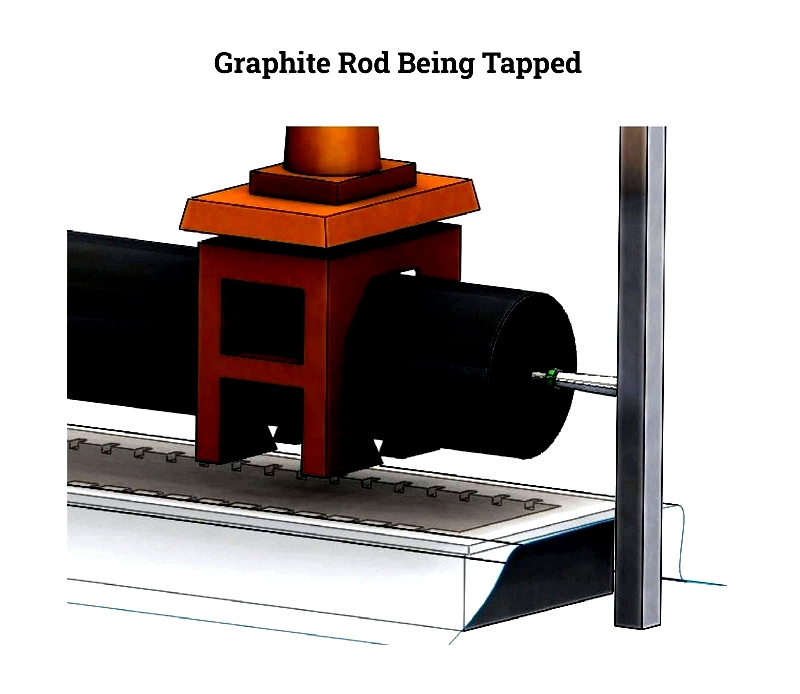

Extrusion produces cost-effective graphite rods and plates. The process involves mixing graphite with a binder, extruding through a die, and high-temperature treatment. Extruded graphite is widely used for electrodes and heating elements.

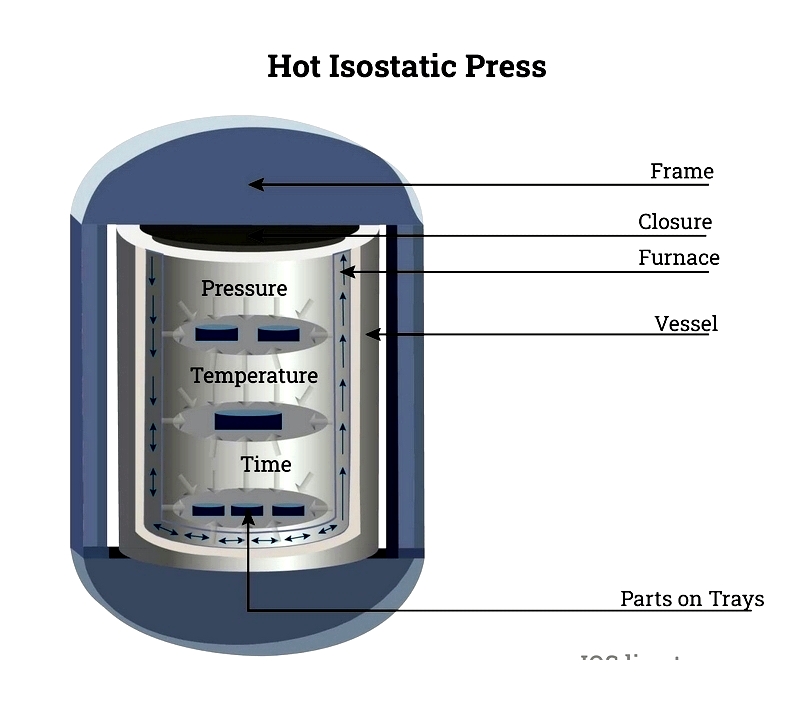

Isostatic Pressing

Isostatic pressing creates high-density graphite for demanding applications. Uniform pressure yields consistent density and grain structure. Post-processing enhances properties for semiconductor and aerospace uses.

Vibrated Graphite and Solidification

Vibration molding produces lower-density graphite at reduced costs. The process ensures uniform structure for furnace linings and casting molds.

Molding Graphite

Conventional molding is ideal for mass-producing standard parts. While not as dense as isostatic pressed graphite, it offers affordability and consistency for electrical and mechanical applications.