Introduction

This article provides an in-depth exploration of fasteners and their applications.

You'll discover detailed information on various topics including:

- What defines a fastener?

- Non-permanent threaded fasteners explained

- Permanent fasteners and their characteristics

- The manufacturing process of fasteners

- Additional relevant information

Chapter One: Understanding Fasteners

Fasteners are mechanical components that join two surfaces or objects, either permanently or temporarily. Non-permanent fasteners enable easy separation without damaging the materials, while permanent fasteners typically require significant force for removal and may cause surface damage. Permanent fasteners are designed to create durable, long-lasting connections.

Fasteners encompass various types including screws, nails, nuts, bolts, and washers, available in multiple sizes and configurations. These essential components are widely used in construction, manufacturing, and industrial equipment assembly.

Chapter Two: Non-Permanent Threaded Fasteners

Fasteners are crucial mechanical devices for joining and securing materials, available in numerous shapes, sizes, and types - from simple nails to industrial-grade bolts. They can be standard or custom-made for specialized applications, with each industry requiring solutions that meet specific performance, safety, and durability standards.

The variety of fasteners stems from the different stresses they must endure, including mechanical loads, vibration, weight, and environmental factors. Engineered for critical applications, they hold together components in automotive, aerospace, electronics, and heavy machinery sectors. Non-permanent threaded fasteners allow secure assembly while permitting disassembly for maintenance or repairs.

Fasteners can be categorized by permanence (permanent vs. non-permanent) and threading (threaded vs. non-threaded). Permanent fasteners like rivets aren't meant for removal, while threaded fasteners include screws and bolts. Understanding these distinctions is vital for selecting the right fastener for each application.

Bolts

Bolts are versatile threaded fasteners that join non-threaded components. They feature specialized heads and threaded shafts that engage with nuts or tapped holes. Material and design choices allow bolts to meet specific strength and corrosion resistance requirements across various industries.

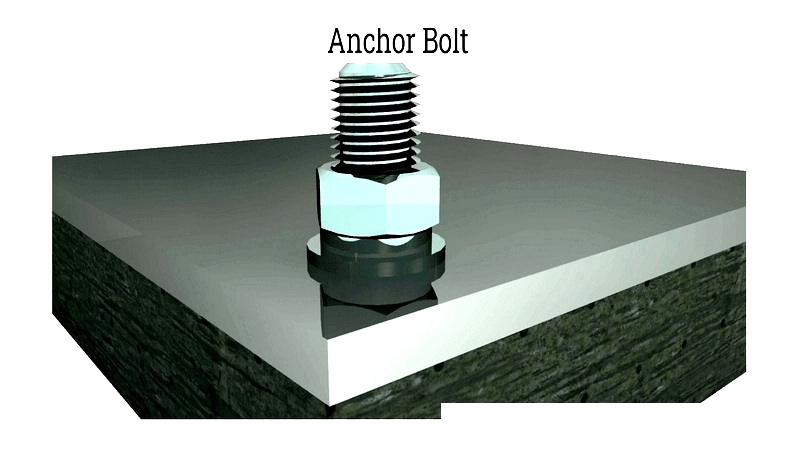

Anchor Bolts

Anchor bolts provide permanent anchoring in concrete foundations, securing structural elements. Available in L-shaped, J-shaped, and sleeve variants, proper selection ensures construction safety and reliability.

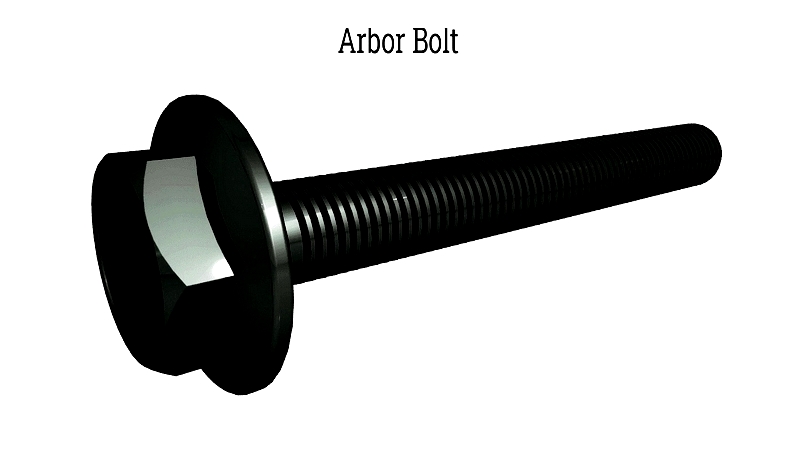

Arbor Bolts

Arbor bolts have fixed washers and reverse threading, primarily used in power tools for secure blade attachment.

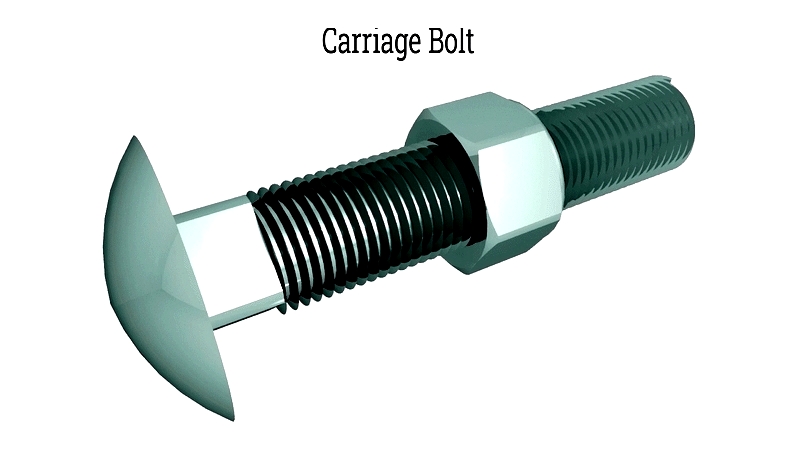

Carriage Bolts

Carriage bolts feature dome heads with square necks that prevent rotation, ideal for woodworking and construction applications.

Wheel Bolts

Precision-engineered wheel bolts secure automotive wheels to hubs, crucial for vehicle safety and performance.

Wheel Nuts

Wheel nuts (lug nuts) fasten wheels to studs, available in various finishes for corrosion resistance and performance.

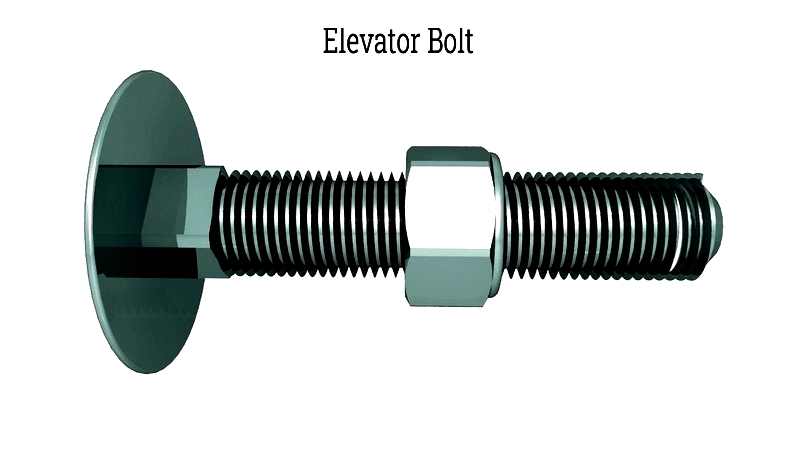

Elevator Bolts

Elevator bolts feature wide heads for conveyor systems and industrial machinery requiring stable fastening.

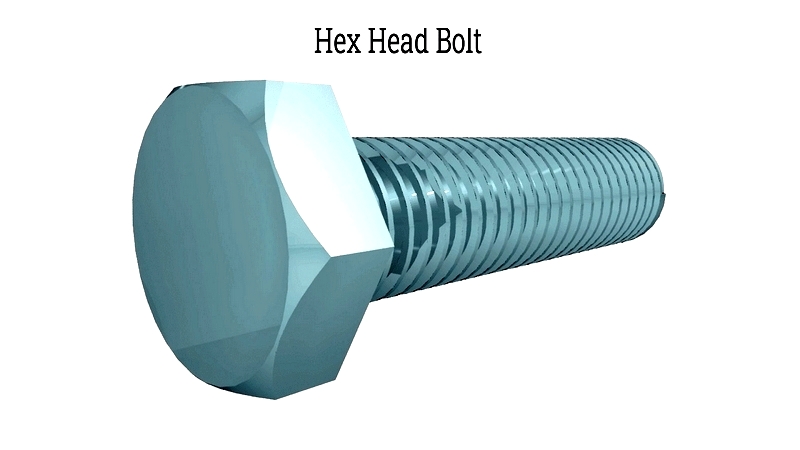

Hex Head Bolts

Hex bolts are widely used in construction and manufacturing, available in partial or full thread designs for different strength requirements.

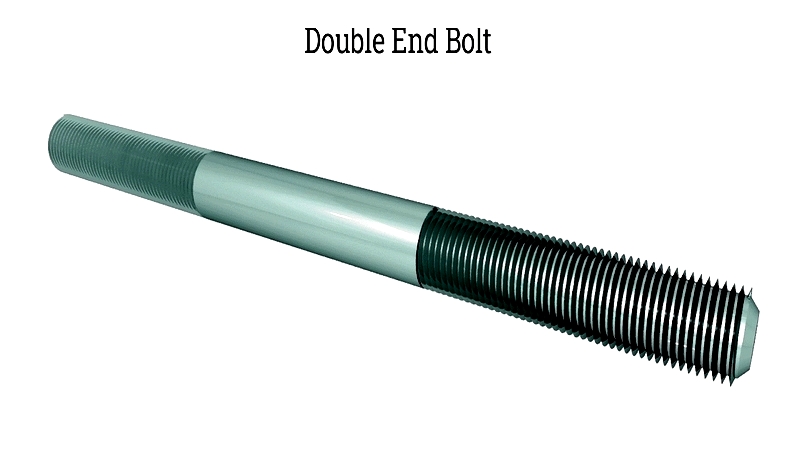

Double End Bolts

Double end bolts thread on both ends, suitable for flange joints in piping systems and power equipment.

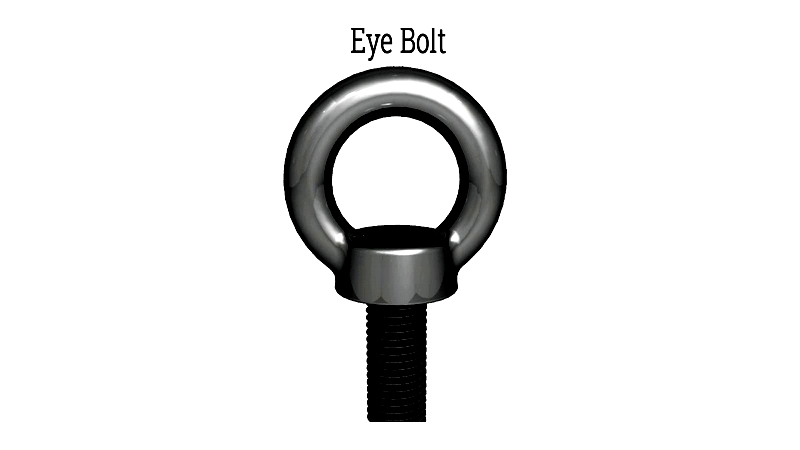

Eye Bolts

Eye bolts feature loops for attaching ropes or cables, used in lifting and rigging applications with specific load requirements.

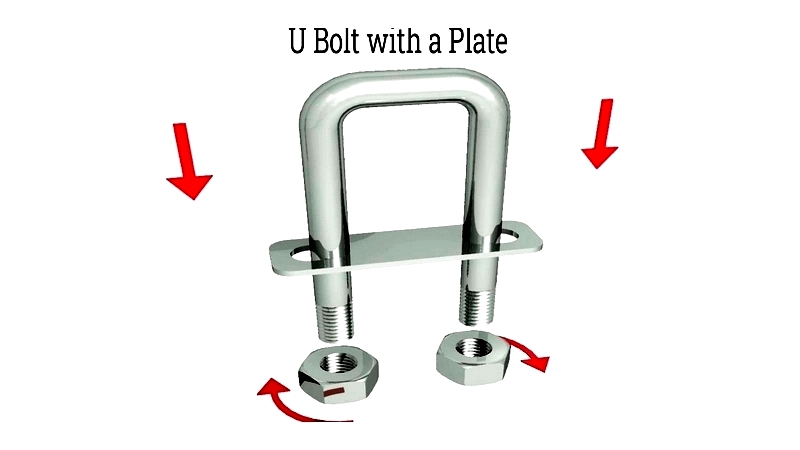

U Shape Bolts

U bolts secure pipes and structural components, available in various materials for different industrial applications.

Specialized bolt types include J bolts, flanged bolts, and shoulder bolts, each serving specific engineering and construction needs.

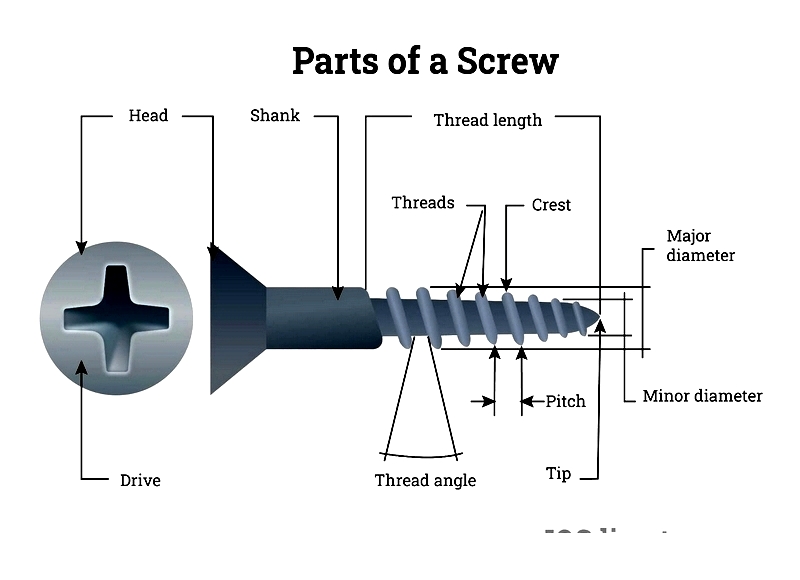

Screws

Screws create their own threads in materials, providing clamping force without nuts. Available in self-tapping and self-drilling varieties, they're used across multiple industries for their versatility and ease of installation.

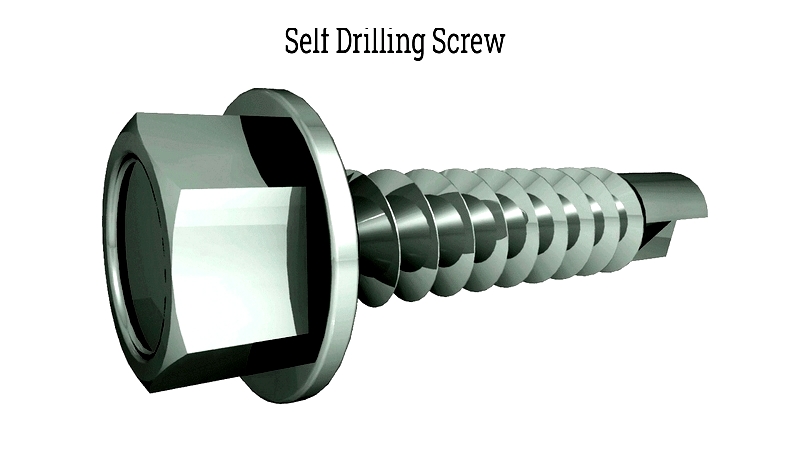

Self-Drilling Screw

Self-drilling screws eliminate pre-drilling with integrated drill points, ideal for metal fabrication and construction.

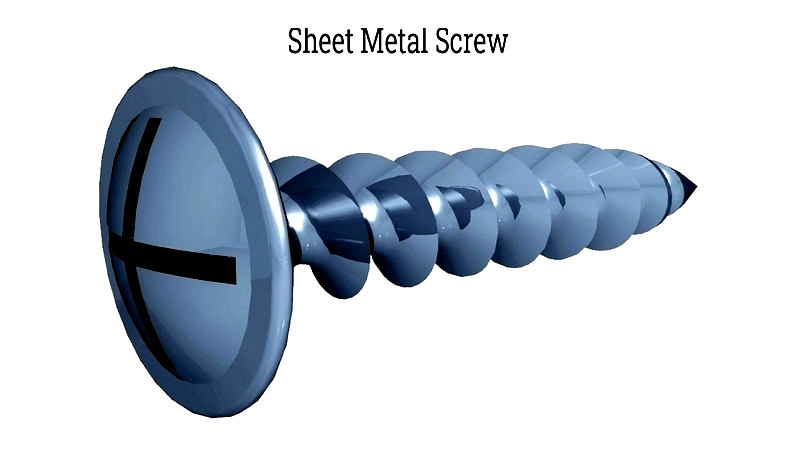

Sheet metal Screw

Sheet metal screws secure metal components with sharp points and full threading for durable fastening.

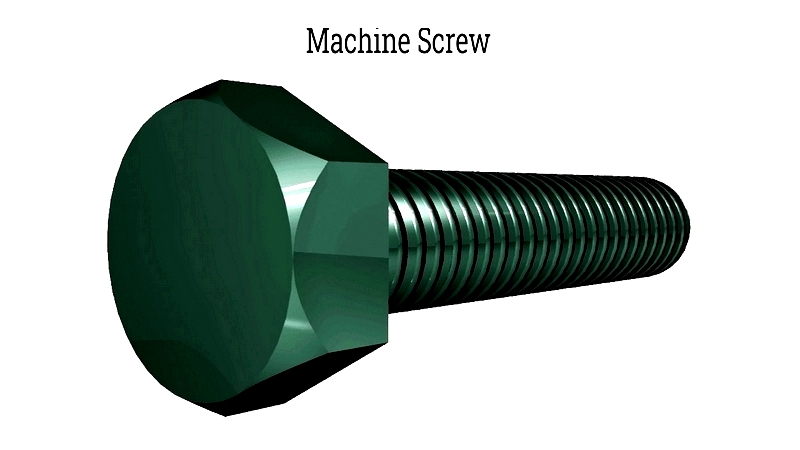

Machine Screw

Precision machine screws assemble electronics and machinery, available in various materials for different requirements.

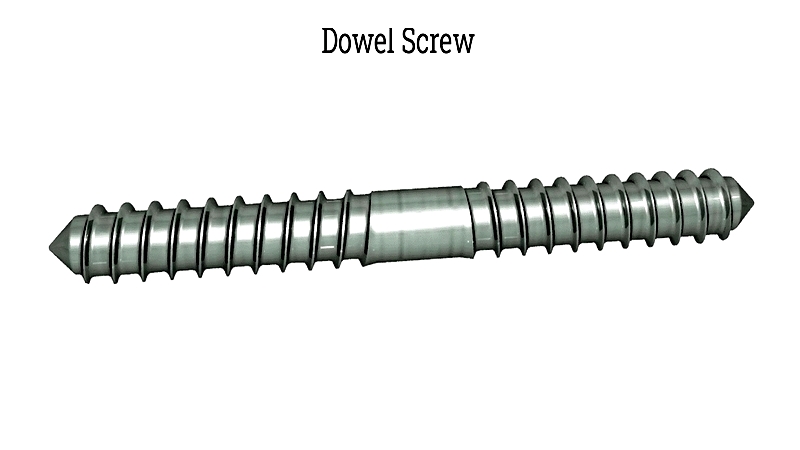

Dowel Screw

Headless dowel screws invisibly join wood pieces, perfect for furniture and cabinetry.

Thread Cutting Screw

Thread cutting screws create new threads in hard materials, essential for machinery and equipment assembly.

Wood Screws

Specially designed for wood, these screws offer superior pull-out strength for various woodworking applications.

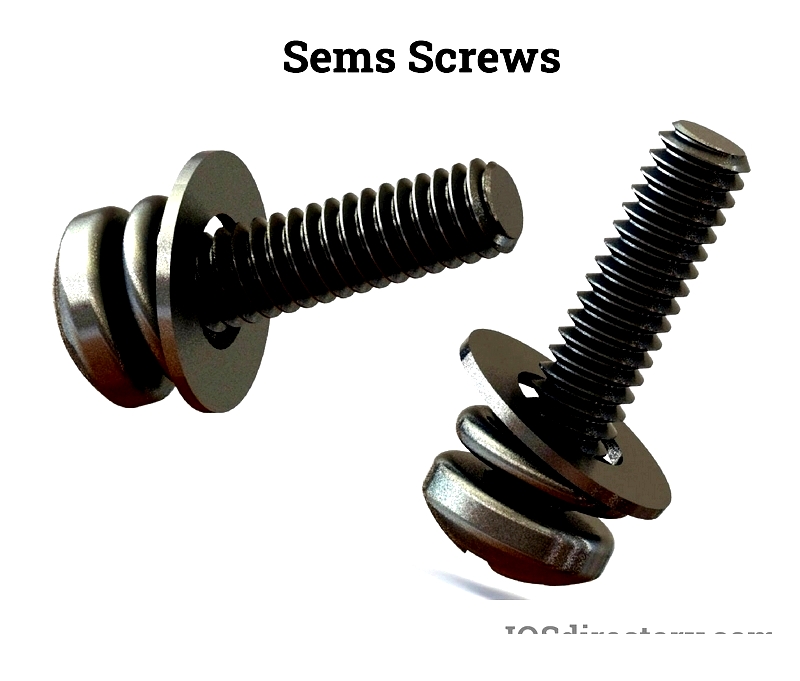

Sems Screws

Sems screws feature integrated washers for stability and vibration resistance, streamlining assembly in automotive and industrial applications.

Nuts

Nuts secure threaded fasteners, providing vibration resistance and load distribution across various industries.

Cap Nuts

Domed cap nuts protect threads and improve appearance in visible applications.

Castle Nuts

Notched castle nuts accept cotter pins for secure locking in high-vibration