Introduction

This article provides an in-depth exploration of ball bearings.

Key topics covered include:

- Ball Bearings Design and Function

- Types of Ball Bearings

- Applications & Benefits of Ball Bearings

- And Much More...

Chapter 1: Ball Bearings Design and Function

This chapter examines the design, structure, and purpose of ball bearings.

Understanding Ball Bearings

Ball bearings are rolling-element bearings designed to support loads, reduce friction, and position moving machine parts for smooth operation.

By using two separate races to contain the balls, ball bearings minimize surface contact and friction between moving components. The rolling motion of balls creates less friction than flat surfaces sliding against each other.

Design of Ball Bearings

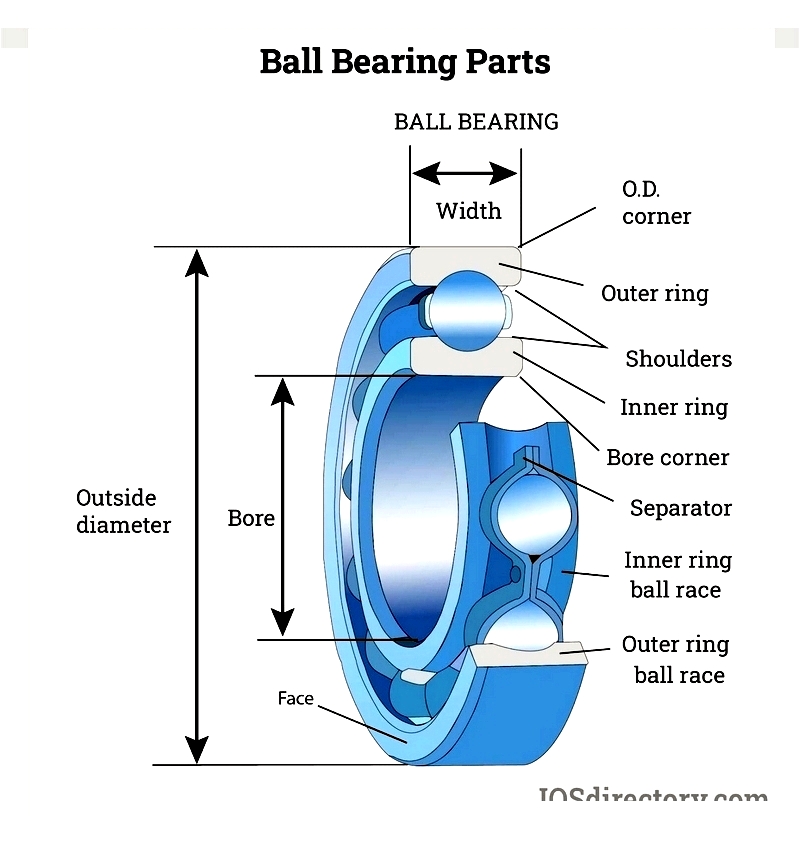

Ball bearings consist of four main components: two races (rings), balls (rolling elements), and a retainer (to space the balls). Angular contact and radial ball bearings feature inner and outer rings designed to support radial loads perpendicular to the rotation axis.

The stationary outer race transfers radial loads, while the inner race attaches to the rotating shaft to support and guide it. Rolling elements carry and distribute loads across raceways.

These elements rotate at different speeds from the inner race while revolving around it. The separator prevents ball-to-ball contact by acting as a buffer between them. Thrust bearings support axial loads parallel to the rotation axis using two equal-sized rings.

Materials Used in Ball Bearings

Ball bearing materials vary, typically matching ring materials for optimal performance - especially important during temperature changes. Common materials include:

Roller Bearing Steel 1.3505/100Cr6

Steel ball bearings primarily use hardened steel balls. Chrome steel, containing about 1% carbon and 1.5% chromium, offers excellent durability and performance.

Martensitic chrome steel balls enhance stability and durability for continuous operation. Roller bearing steel provides durability and corrosion resistance for demanding applications.

Stainless Steel 1.4401 and 14401

Used in plastic ball bearings, non-hardened stainless steel balls resist corrosion from saltwater and alkalis. More economical than glass balls, they're compatible with plastic rings.

Soda-Lime Glass

For metal-free bearings, soda-lime glass balls offer chemical resistance. Suitable for mild chemical environments, they're sometimes called "lemon glass" due to their light green tint.

Borosilicate Glass

Borosilicate glass provides superior chemical resistance and handles strong acids. Benefits include:

- Excellent heat resistance and thermal shock tolerance

- Mechanical stability

- Very low coefficient of linear expansion

Aluminum Oxide

Ceramic ball bearings use lightweight aluminum oxide balls that resist corrosion, abrasion, and high temperatures. They withstand water, acids, and salt solutions but avoid strong alkalis and certain acids. These white-to-ivory ceramics meet ASTM F 2094 Class II/III standards.

Silicon Nitride

Silicon nitride ceramic balls are lightweight, tough, and corrosion-resistant. While resistant to many chemicals, they may be affected by certain corrosives. These black, mother-of-pearl-hued balls offer insulation, self-lubrication, and thermal shock resistance.

Ball Bearing Specifications

Key specifications include dimensions and operating characteristics:

Ball Bearing Dimensions

Critical dimensions to consider:

-

Bore Diameter

Metric bore sizes follow a standard system where sizes 04 and above multiply by 5 to get millimeters. Hex bores measure across-the-flats.

-

Outside Diameter

Includes housing but excludes flanges in flanged bearings. Outer ring width accounts for the entire bearing width.

-

Overall Width

Includes locking collar if present in the bearing assembly.

Operating Specifications

- Grease-lubricated bearings have lower speed ratings than oil-lubricated ones

- Dynamic thrust is the constant axial load a bearing group can sustain for one million inner ring revolutions

- Dynamic radial load is the constant load a bearing group can endure for one million inner ring revolutions

Ball Bearing Load, Fatigue, and Lifespan

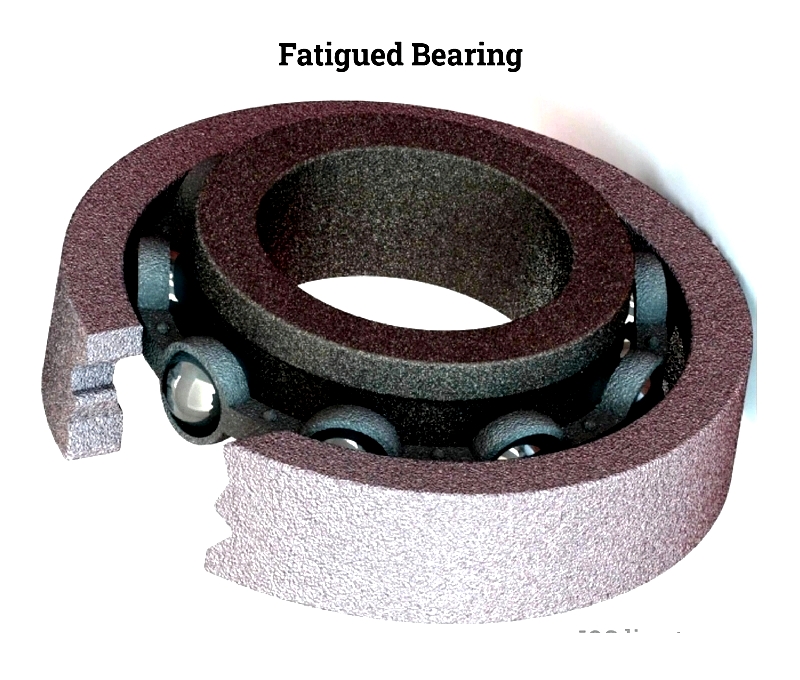

Optimizing bearing life requires minimizing ball-to-raceway contact and proper lubrication. Ball bearings handle dynamic/static, radial/axial loads. Considering these variables is crucial for determining operating loads.

They support higher dynamic/radial loads but lower static/axial loads. Non-elastic deformation first appears as flattened ball areas. Industry standards suggest bearings last up to one million rotations while maintaining 90% functionality - known as bearing fatigue.

Function of Ball Bearings

Ball bearings reduce rotational friction while supporting axial and radial loads. Two races contain the balls that transfer loads - one race typically attaches to a rotating shaft, the other remains stationary.

As one race rotates, the balls roll with it, creating less friction than sliding surfaces. Though contact areas are smaller, allowing some misalignment between races.

Chapter 2: Types of Ball Bearings

This chapter details various ball bearing types used across industries. Understanding each type's characteristics helps select optimal solutions for mechanical systems.

Angular Contact Ball Bearings

Precision bearings with offset raceways accommodate combined axial and radial loads simultaneously. Ideal for high-speed applications like machine tool spindles and automotive gearboxes.

Available with shields/seals and various materials (ceramic hybrid, stainless steel, etc.) for different environments. Common in aerospace, robotics, and precision manufacturing.

- Single Row: High load capacity for primarily one-direction axial loads, often used in pairs

- Double Row: Combines two single-row bearings for increased load capacity in compact space

- Four Point: Supports substantial axial loads from any direction, used in rotary tables and heavy machinery

Deep Groove Ball Bearing

The most common bearing type, featuring deep raceway grooves for high-speed operation and moderate radial/axial loads. Used in electric motors, appliances, and automotive applications.