Introduction

This article provides an in-depth exploration of CNC machining.

You will learn about key topics including:

- What is CNC?

- Open loop and closed loop machine systems

- The CNC manufacturing process

- Types of CNC machines and operations

- Types of CNC software

- What is a CNC machine?

Chapter 1: Understanding CNC

Computer Numerical Control (CNC) is an advanced manufacturing process where programmed software controls factory machinery operations. This technology is essential for managing complex machines like grinders, lathes, mills, and routers. CNC overcomes the limitations of manual operations that depend on hand-operated controls. Fundamentally, CNC enables precise three-dimensional cutting through programmed instructions, optimizing production and significantly improving efficiency.

CNC machines operate using a numerical control system guided by software that manages the production process. The programming language, G-code, controls the machine's detailed operations. CNC allows operators to program machines for repetitive, predictable tasks. Due to its precision and effectiveness, CNC is widely used in metal fabrication and plastic production industries.

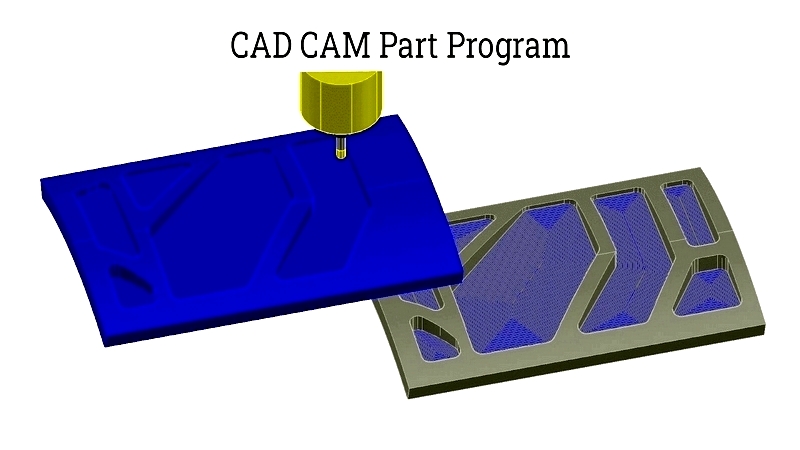

CNC programming begins with a CAD design, which is converted into computer code compatible with the CNC system. A trial run verifies the program's accuracy, identifying and correcting potential errors. After adjustments, the final program is loaded into the machine, and production begins.

Open Loop and Closed Loop Control Systems

CNC machines use either open-loop or closed-loop systems to control material processing. Open-loop systems operate in one direction until completion, while closed-loop systems receive feedback to correct errors like feed speed or positioning.

Open-loop systems are simple, relying on calibration for accuracy. Material is fed into the machine, which produces a finished part without in-process adjustments. Precise calibration is crucial to avoid errors. A washing machine is an example of an open-loop system: it completes its cycle without checking results.

Closed-loop systems are more complex, incorporating controllers, amplifiers, and feedback mechanisms. Unlike open-loop systems, they continuously monitor and adjust operations. For instance, a home heating system activates when temperatures drop below a set level and adjusts until reaching the desired temperature. Though slower due to monitoring, these systems are easier to calibrate as they make most adjustments automatically.

CNC machines reference multiple axis points to remove material from workpieces. Systems vary from 3 to 5 axes. A basic three-axis system keeps material stationary while the machine moves along the XYZ plane. Four-axis systems add capabilities like drilling or specific cuts. Five-axis systems offer greater complexity, manipulating five material sides for highly technical components.

The CNC Manufacturing Workflow

CNC is a subtractive process, removing material layers to create custom shapes, unlike additive methods that build by layering. CNC production is fully automated, ensuring high precision and reliability.

Successful CNC manufacturing depends on accurate programming. Software must contain precise instructions for the machine to operate within its limits. CAD (Computer-Aided Design) software drives CNC functionality. Careful programming minimizes errors and downtime, maximizing efficiency.

After finalizing a CAD design, it is converted to CNC-compatible formats like STEP or IGES. STEP files, a standard for product data exchange, contain 3D information readable by various programs. IGES files serve similar purposes, transferring CAD files as diagrams or models. Both formats work for CNC processing.

CNC machines use programming languages like G-code and M-code. G-code controls operations like movement speed and tool functions, while M-code manages start and stop commands.

Before running a CNC program, machine setup is critical. This includes securing the workpiece and installing tools like lathes or cutters. Each tool must be precisely aligned.

Like verbal instructions guide a person, CNC programs direct machines through command sequences. once started, production follows the programming step by step, resulting in custom-designed parts.