Introduction

This article provides an in-depth exploration of rubber gaskets.

Continue reading to learn about:

- What are Rubber Gaskets?

- Benefits of Rubber Gaskets

- Industrial Uses of Rubber Gaskets

- Different Rubber Gasket Materials

- And more...

Chapter 1: What is a Rubber Gasket?

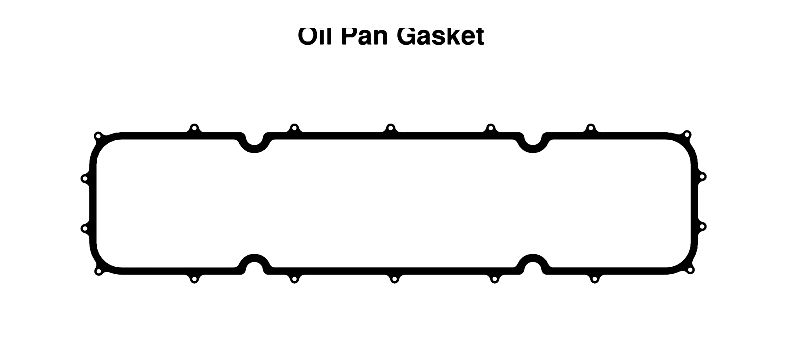

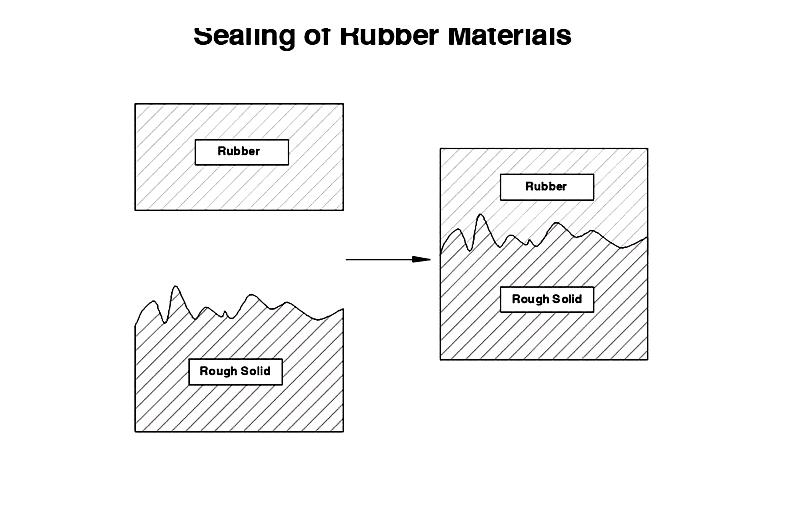

Rubber gaskets are flexible components designed to seal small gaps between connected surfaces or joints. They find common use in various applications, including sealing flange faces in piping systems, cylinder heads in vehicles, engine blocks, tank rims, covers, and door edges. These gaskets work by conforming to surface irregularities when compressed, creating a strong seal through deformation.

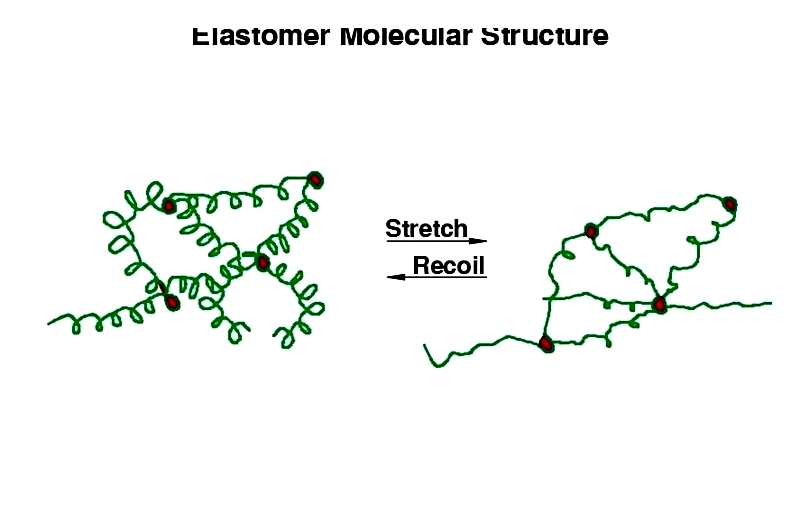

Rubber's excellent sealing properties come from its elastomeric nature. Both natural and synthetic rubbers belong to the elastomer family, known for their exceptional elasticity. This flexibility results from cross-linked polymer chains forming amorphous structures. The weak intermolecular forces between these chains allow them to adapt under stress, enabling elastomeric gaskets to conform to various surface profiles for reliable sealing.

Chapter 2: Advantages of Rubber Gaskets

Rubber gaskets offer numerous benefits compared to metal and other non-metal gaskets due to their unique properties. Their exceptional elasticity allows them to deform and recover, creating long-lasting, leak-proof seals in diverse applications. Easier to manufacture and customizable from various elastomeric materials, rubber gaskets serve as preferred sealing solutions for industrial, automotive, plumbing, and high-purity applications. Below are key reasons why rubber gaskets excel in critical sealing environments.

Cost-Effective and Easy to Manufacture

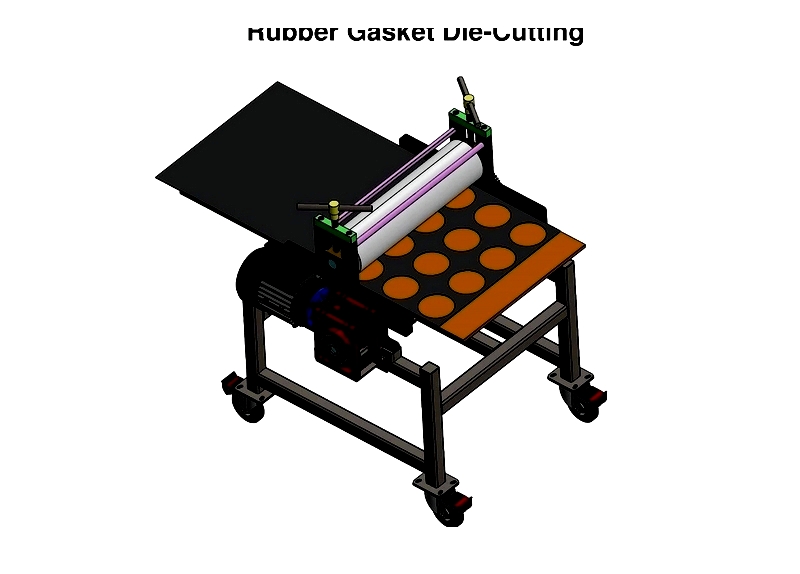

Manufacturers produce rubber gaskets by blending raw rubber compounds with additives and forming them into desired shapes. Both thermosetting and thermoplastic rubbers offer excellent processability. In liquid or uncured states, rubber flows smoothly into intricate molds, enabling high-precision manufacturing through compression, transfer, and injection molding. After curing, the material can be cut, stamped, or machined into custom shapes.

Compared to metal gaskets, rubber gaskets require lower heat and pressure during production, reducing tooling costs, energy consumption, and overall expenses. This makes them economical for high-volume production and prototyping, offering industries scalability and flexibility with fast turnaround times.

Excellent Sealing Properties for Leak Prevention

Rubber's viscoelastic properties allow gaskets to stretch, compress, and recover without damage. This flexibility enables them to conform to uneven surfaces, filling micro-irregularities for reliable sealing. Unlike metal gaskets that rely on compression, rubber gaskets create uniform seals with lower bolt torque, maintaining integrity under thermal cycling and vibration in demanding environments.

By minimizing seal failure risks, rubber gaskets reduce downtime and enhance equipment safety and efficiency in high-pressure, high-temperature, and chemically aggressive applications.

Wide Selection of Rubber Types for Every Application

Rubber gaskets can be engineered from various base polymers to meet specific requirements. Common materials include natural rubber, silicone, EPDM, neoprene, nitrile, Viton, polyurethane, butyl, and SBR. Manufacturers can tailor properties like temperature resistance, chemical compatibility, and mechanical strength through compounding techniques.

This versatility surpasses metal gaskets (typically stainless steel) and mineral gaskets (mica or vermiculite), with only compressed fiber gaskets offering comparable adaptability through elastomeric components.

Highly Resistant to Chemicals, Heat, and Environmental Factors

Properly specified rubber gaskets demonstrate outstanding durability against corrosive chemicals and harsh conditions. Material selection determines chemical resistance - fluorocarbon elastomers like FKM resist strong acids and extreme temperatures, while SBR, butyl, and EPDM offer excellent weatherability. Industries rely on specialized rubber gaskets for chemical processing, automotive fuel systems, and HVAC applications to maximize service life and minimize maintenance.

Customizable Physical Properties for Performance Needs

Rubber gaskets offer customizable characteristics like hardness, compression set, tensile strength, and low-temperature flexibility. This tunability balances requirements for sealing tightness, pressure containment, and mechanical wear. Softer materials suit low-pressure applications, while harder compounds handle high-pressure or chemically aggressive environments, maintaining performance under fluctuating loads.

Easy Fabrication into Custom Shapes

Rubber gaskets accommodate various fabrication methods. Large sheets allow custom cutting for irregular flanges, while laser cutting produces precise, intricate geometries. Extrusion and injection molding create seamless profiles for high-volume applications like door seals and o-rings, using CAD-assisted tooling for consistent results across automotive, aerospace, and marine industries.

FDA-Approved and Food-Grade Options

Specialized rubber compounds meet FDA and NSF standards for food, beverage, and pharmaceutical applications. Food-grade materials like nitrile, silicone, and EPDM resist bacterial growth and cleaning agents while maintaining performance. These gaskets ensure hygiene and compliance in food processing, laboratories, and pharmaceutical equipment handling consumables.

Long Service Life and Maintenance Advantages

Rubber gaskets offer extended service life due to their resilience and resistance to permanent deformation. Their non-corrosive nature prevents bonding to flanges, simplifying maintenance in chemical processing, power generation, and water treatment facilities. This longevity reduces downtime and supports cost-effective maintenance schedules.

Frequently Asked Questions about Rubber Gaskets

- Which industries benefit most from rubber gaskets? - Automotive, aerospace, oil and gas, water treatment, food processing, pharmaceuticals, electrical, HVAC, and marine industries value their versatility and reliability.

- How to select the best rubber gasket material? - Consider temperature range, chemical exposure, mechanical stresses, pressure ratings, and regulatory standards.

- What's the typical rubber gasket lifespan? - Industrial-grade gaskets typically last several years when properly selected and maintained.