Introduction

This article provides a comprehensive overview of industrial fans and their applications.

You will learn about:

- The definition of industrial fans

- Different types of industrial fans

- Common uses of industrial fans

- Industrial fan design principles

- And additional relevant information

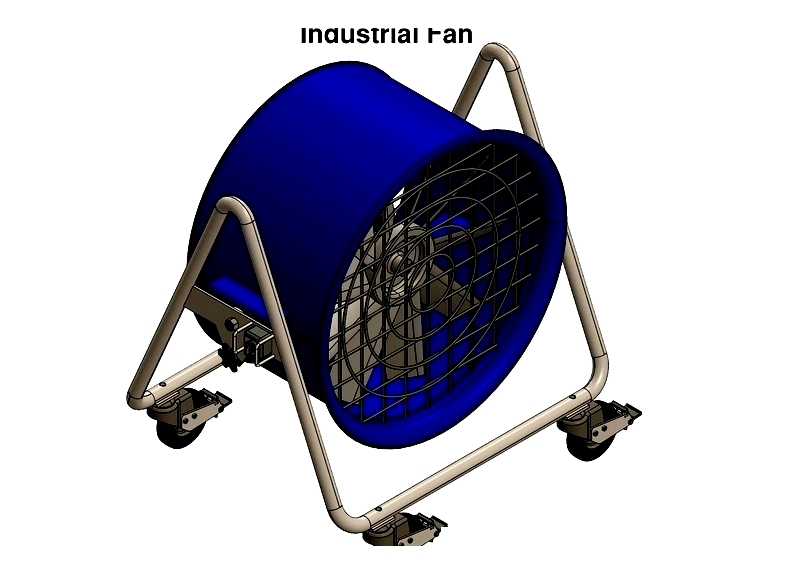

Chapter One - What is an Industrial Fan?

Industrial fans are durable air movement devices designed to withstand demanding conditions, constructed with high-quality materials for long-lasting performance. These fans maintain consistent airflow and pressure through robust components like roller or ball bearings. Their construction features secure motor enclosures, seamless welds, and housings made from materials like cast aluminum and stainless steel.

These fans serve multiple purposes, from cooling large commercial spaces to regulating temperatures during complex assembly processes. Proper air circulation is essential for maintaining safe working conditions and optimizing equipment efficiency in facilities of all sizes.

Chapter Two - Types of Industrial Fans

Industrial fans are vital for maintaining air quality, temperature control, and safe working environments across various industries. They enhance ventilation in manufacturing, processing, HVAC systems, power plants, and mining operations. Fan selection depends on factors like airflow volume, pressure needs, space limitations, energy efficiency, noise levels, and environmental conditions. While models vary, all industrial fans primarily fall into two categories: centrifugal and axial.

Centrifugal fans, also called blowers or squirrel cage fans, operate like pumps. Their rotating impellers draw air inward and discharge it at a 90° angle to create static pressure. These high-pressure fans excel in ductwork, dust collection systems, HVAC setups, and industrial ventilation requiring substantial airflow.

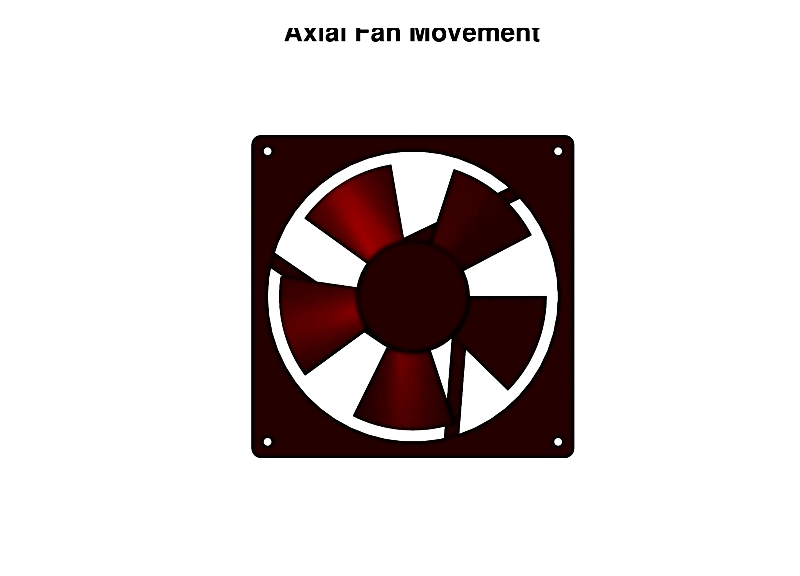

Axial fans, or industrial propeller fans, move air parallel to their rotation axis. Their performance depends on blade shape, size, and housing design. These fans handle large air volumes at low pressure, making them ideal for general ventilation, cooling, and exhaust systems in tunnels, warehouses, and industrial settings.

Air Foil Fan

Air foil fans use aerodynamic blades to move large air volumes efficiently and quietly. Common in cooling towers and HVAC systems, their adjustable blades allow precise airflow control. These fans excel where low noise and high efficiency are priorities.

Backward Curved Fan

Backward curved fans feature swept blades that reduce dust buildup and improve efficiency. Their design generates high pressure with low energy use and noise, making them ideal for heavy-duty ventilation and pollution control systems.

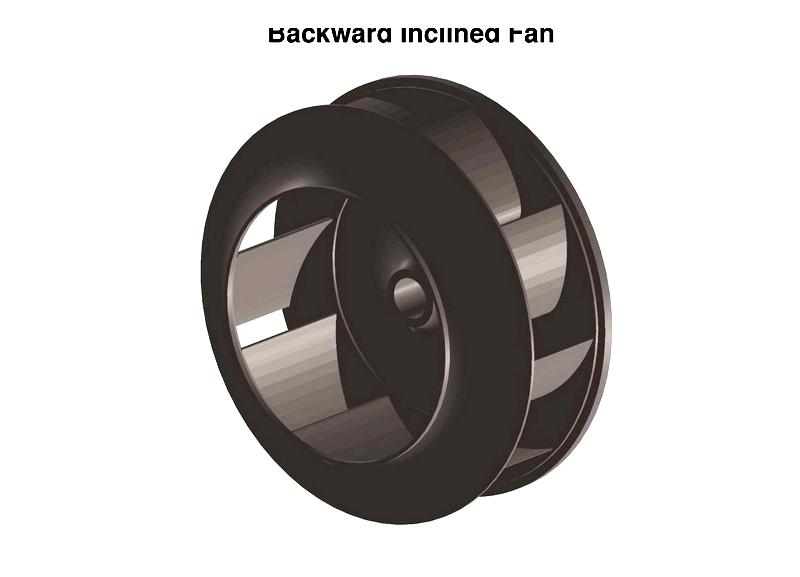

Backward Inclined Fan

Backward inclined fans have flat, angled blades that minimize airflow disruption. Their simple design reduces vibration and noise, making them suitable for industrial ventilation, cleanrooms, and high-temperature applications.

Radial Blade Fan

Radial blade fans feature durable, flat blades resistant to abrasion. Their design handles dust and particulates well, making them suitable for material handling, conveying, and filtration systems in demanding industries like woodworking and foundries.

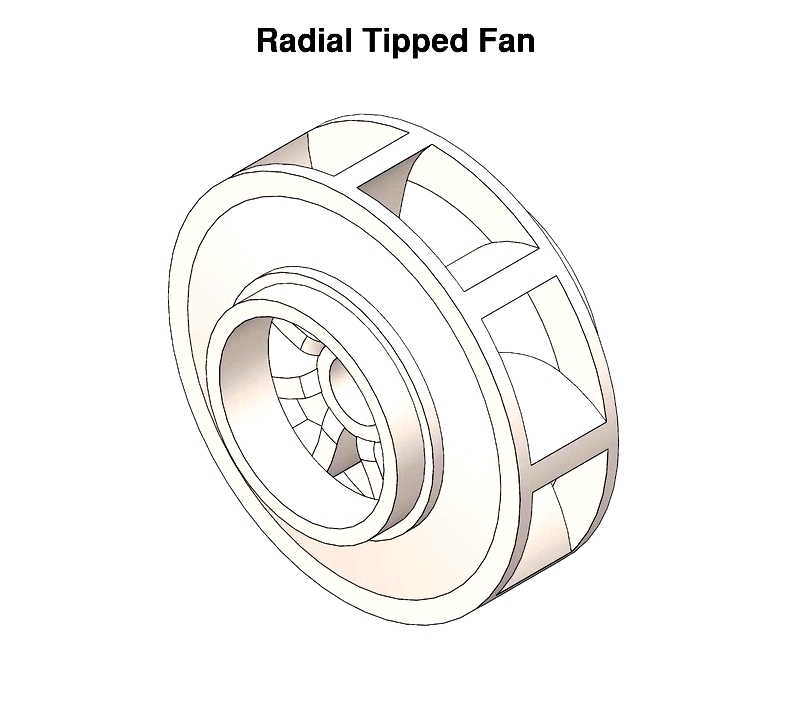

Radial Tipped Fan

Radial tipped fans combine radial impeller strength with backward inclined efficiency. They handle particulates well and operate under moderate to high pressures, making them ideal for dust collection and industrial exhaust systems.

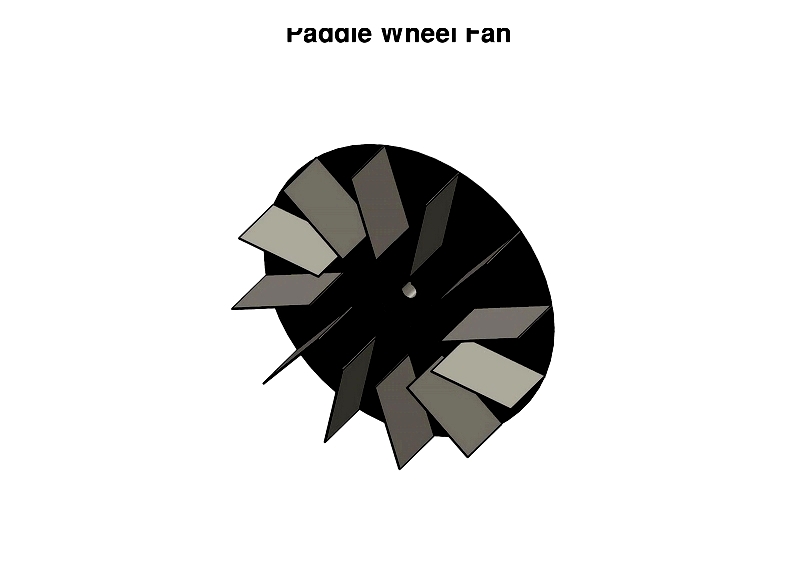

Paddle Wheel Fan

Paddle wheel fans feature heavy-duty radial blades for rugged applications. Their robust construction suits material handling, high-temperature processes, and harsh industrial environments like foundries and incinerators.

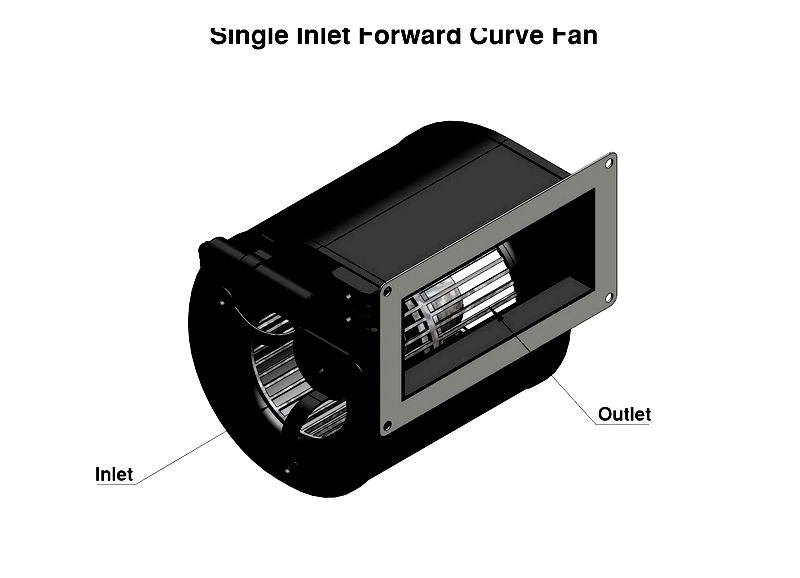

Forward Curved Fan

Forward curved fans, or squirrel cage blowers, convert high-velocity air to low-velocity flow. Common in HVAC systems, they provide compact, quiet operation for low-to-medium pressure applications.

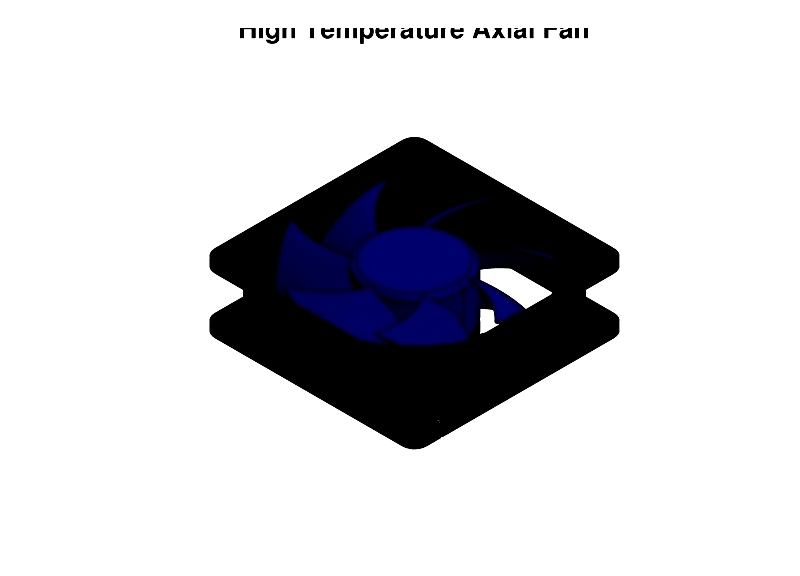

High Temperature Axial Fans

These fans withstand temperatures up to 100°C (212°F) or higher. Their heat-resistant design makes them essential for oven ventilation, kiln cooling, and hot gas exhaust in industrial settings.

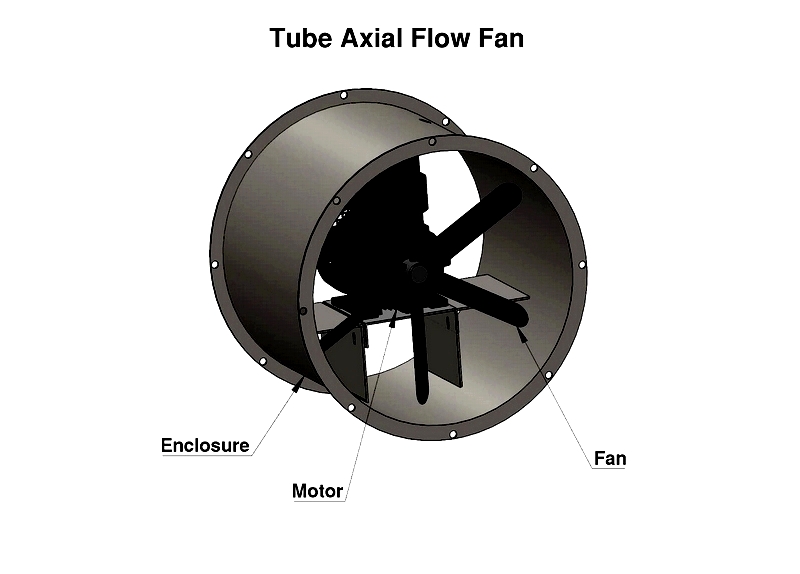

Tube Axial Fan

Tube axial fans feature disk impellers in cylindrical housings for direct airflow. They suit industrial ventilation, process cooling, and corrosive or high-temperature applications with various impeller materials.

Vane Axial Fan

Vane axial fans use guide vanes for efficient, directional airflow. Their balanced design suits smoke exhaust, pressurization, and mine ventilation systems, often featuring high-temperature motors and vibration controls.

Variable Pitch Fan

Variable pitch fans allow real-time airflow adjustment through blade angle changes. Their adaptability benefits process plants, cooling towers, and mining operations needing flexible air volume control.

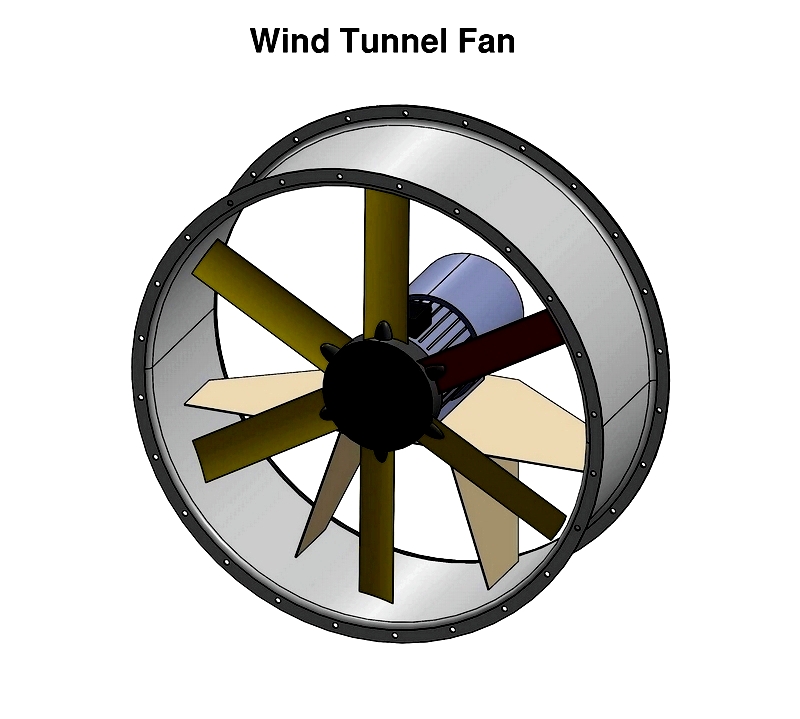

Wind Tunnel Fan

Wind tunnel fans generate adjustable, high-capacity airflow for aerodynamic testing. Their durable construction serves aerospace, automotive, and indoor skydiving applications requiring precise air movement control.

Beyond engineering, these fans also support training and recreational facilities needing controlled airflow environments.

Cooling Fan

Industrial cooling fans maintain comfortable temperatures for personnel and equipment. Their high-volume, low-speed design benefits warehouses, production lines, and electrical cabinets, helping facilities meet safety standards.