Introduction

This article offers a comprehensive overview of steam boilers.

Continue reading to find answers to key questions such as:

- What exactly is a steam boiler?

- Different types of steam boilers

- The manufacturing process of steam boilers

- Common applications of steam boilers

- And additional valuable information...

Chapter One - Understanding Steam Boilers

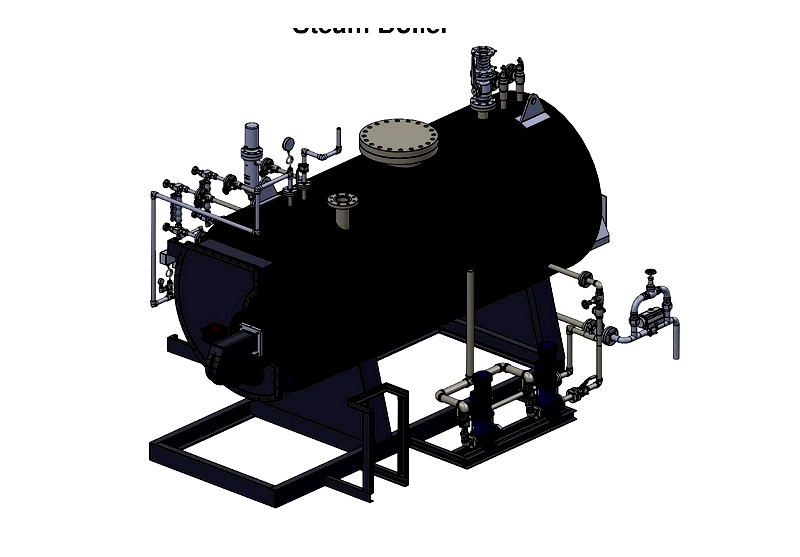

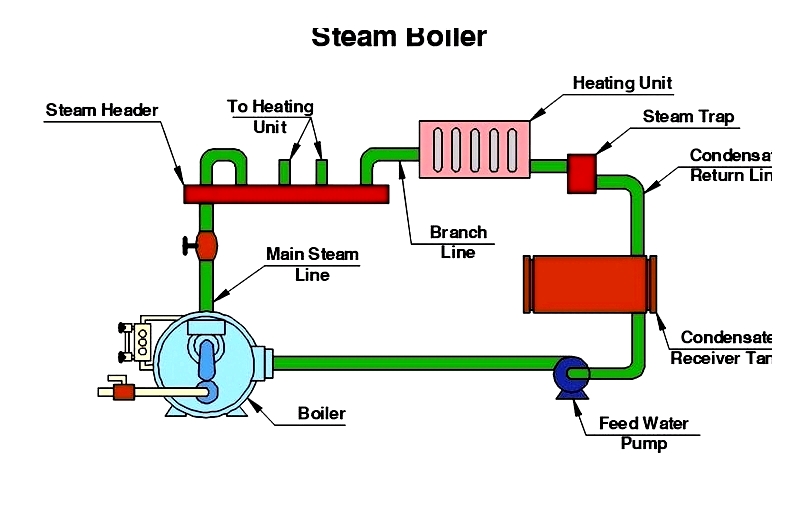

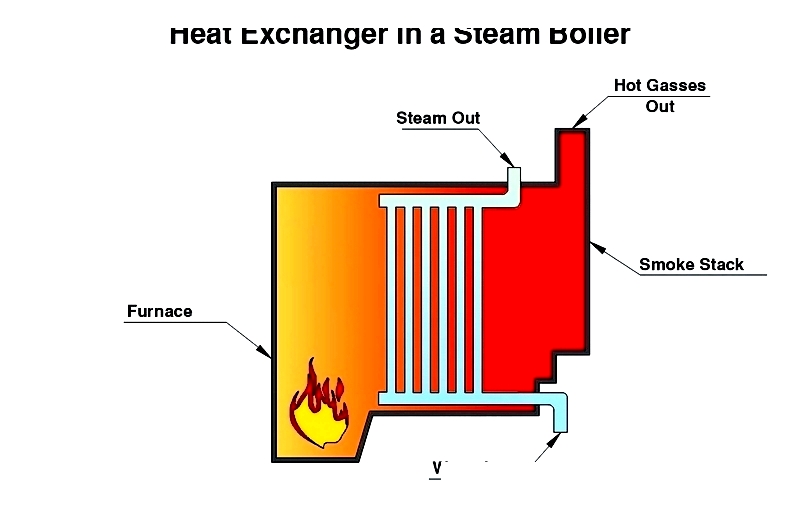

A steam boiler is a specialized device that generates steam by heating water. Functioning as a heat exchanger, it converts water into steam for various external applications. The boiler typically consists of a combustion chamber and a water reservoir. Available in multiple sizes, steam boilers range from compact units to large-scale systems designed for heavy-duty operations.

Steam boilers produce steam through fuel combustion that heats water. This process employs three fundamental heat transfer methods: radiation, convection, and conduction.

Chapter Two - Steam Boiler Varieties

Steam boilers serve as crucial elements in industrial and commercial heating systems, categorized by their construction, mobility, tube configuration, fuel type, and operating pressure. While early steam boilers were efficient, they often lacked modern control systems, making them more hazardous than contemporary models that incorporate advanced safety features. Boiler size, fuel choice, and design are customized for specific industrial, commercial, or residential needs, addressing diverse heating and steam requirements. Common fuel options include electricity, wood, natural gas, coal, oil, and other fossil fuels, each differing in operational costs, efficiency, emissions, and environmental impact. With growing demand for efficient heat and power generation, industries are increasingly adopting alternative fuels like biomass and refuse-derived fuel (RDF) to support sustainability goals, reduce carbon emissions, and meet environmental standards. Recognizing the main steam boiler types and their applications is essential for selecting the ideal system that ensures energy efficiency, cost-effectiveness, and process optimization.

Steam Boiler Classifications

Hot Water Boilers

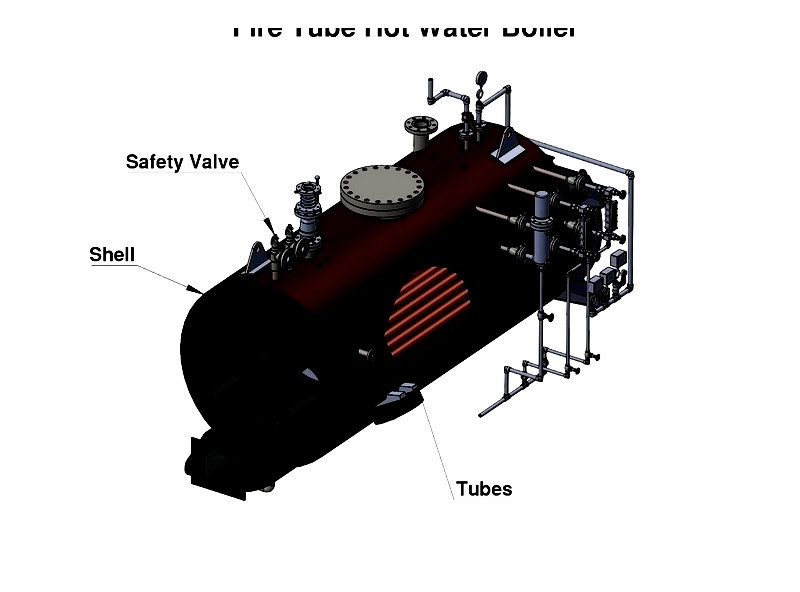

Hot water boilers are pressurized vessels that transfer thermal energy to water for hydronic heating and hot water supply. Constructed from durable materials like stainless steel, cast iron, aluminum, and carbon steel, these boilers withstand high temperatures and operating pressures. They're widely used in building heating systems, radiant floor heating, and various pressure heat delivery processes. These units are further classified by their internal tube arrangements.

Hot water boilers employ either fire tube or water tube designs. Fire tube boilers channel combustion gases through tubes submerged in water, heating the surrounding water. Water tube boilers circulate water inside tubes while combustion gases flow externally, enabling faster heat transfer and higher pressure steam. Selecting the appropriate hot water boiler depends on load demands, water quality, energy efficiency, and available fuel sources.

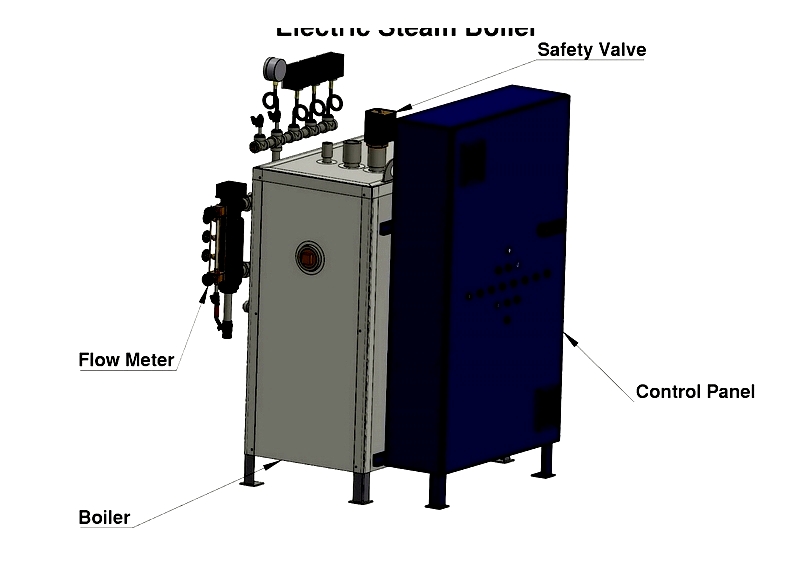

Electric Boilers

Electric boilers utilize heating elements to directly generate heat for steam or hot water production, offering quick, efficient thermal output without combustion. As environmentally friendly systems with low emissions, electric steam boilers produce no exhaust gases or greenhouse emissions, making them ideal for facilities prioritizing air quality and environmental compliance. Beyond their energy efficiency, electric boiler systems are highly durable, requiring minimal maintenance due to fewer moving parts and no burners.

Electric steam boilers are increasingly popular for small-scale or decentralized applications, especially where noise and emissions are concerns. However, monitoring water mineral deposits is crucial to prevent scaling that could reduce efficiency and reliability.

Gas Boilers

Gas steam boilers use natural gas or propane as their primary fuel source, ranking among the most efficient and cost-effective options for industrial and commercial use. The gas is delivered to burner systems that ignite and heat exchangers, transferring thermal energy to water or producing steam. Available in condensing and non-condensing models, these boilers offer lower emissions and reduced operating costs compared to oil or coal-fired units.

Gas-fired boilers are well-suited for space heating, process heat, and various steam applications across manufacturing, food processing, chemical production, and institutional facilities. Natural gas's clean combustion contributes to smaller carbon footprints, higher efficiency, and compliance with environmental regulations.

Low Pressure Boilers

Low pressure steam boilers operate at 10-15 psi with output temperatures around 300°F (149°C). Ideal for applications needing consistent moderate temperatures, these boilers serve space heating, humidification, and light manufacturing processes. Their popularity stems from safe operation, quick response times, and lower maintenance needs versus high pressure systems. Common applications include schools, hospitals, commercial buildings, and small industries where reliable steam generation is essential.

High Pressure Boilers

High pressure steam boilers generate elevated steam pressures to power turbines and heavy machinery in industries like chemical processing, power generation, and petrochemical refining. These systems use high-efficiency pumps to deliver steam at 15-800 psi and temperatures exceeding 250°F (121°C), maximizing energy output for continuous, demanding operations.

For safety and efficiency, high pressure boilers require regular monitoring of pressure, temperature, water levels, and fuel delivery. They may operate in batch or continuous modes, depending on process requirements. Considerations should include redundancy, control technology, and safety features when selecting these boilers.

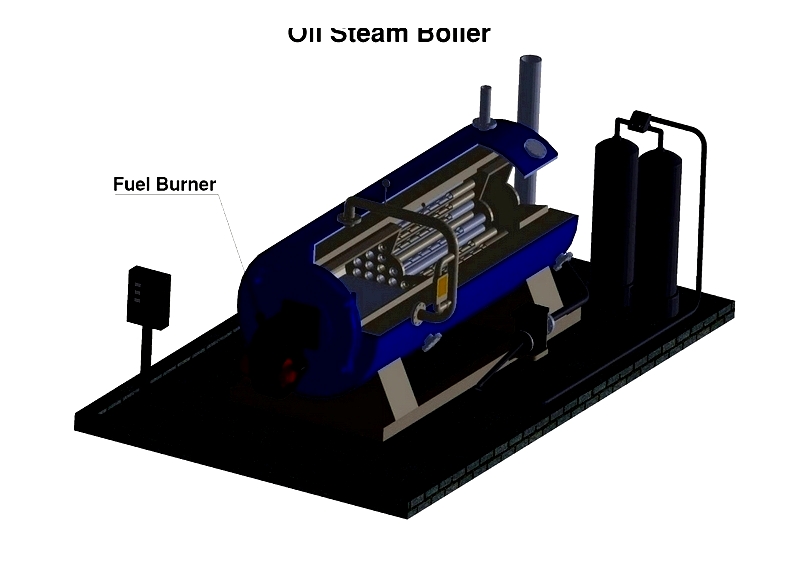

Oil Boilers

Oil steam boilers use oil-based fuels like No.2 heating oil for combustion, heating exchangers or water tanks to produce efficient steam. With efficiency rates often exceeding 90%, they provide alternatives where gas isn't available.

While typically more expensive initially than gas boilers, oil-fired systems often have longer operational lifespans. Fuel storage requires on-site tanks that need regular maintenance. Modern oil boilers feature advanced burner controls and low-emission designs for improved efficiency and compliance.

Water Tube Boilers

Water tube boilers circulate water inside tubes surrounded by combustion heat, efficiently generating high-pressure steam through tangential pressure. This design offers superior pressure resistance, rapid steam production, and high thermal efficiency.

Preferred for industrial power plants and continuous processes, water tube boilers come in various designs (D-type, O-type, A-type) optimized for specific steam outputs and pressure requirements.

Specialized Boiler Designs

La Mont, Benson, and Loeffler boilers are advanced water tube designs using forced circulation and draft fans to deliver large volumes of high-pressure steam efficiently. Water circulates through small-diameter tubes via centrifugal pumps, maximizing heat transfer while minimizing overheating risks. Integrated economizers preheat feedwater using waste heat, reducing fuel consumption and emissions.

These specialized boilers are commonly used in power plants, marine applications, and demanding industrial processes requiring consistent steam output and rapid startup.